IT, mobility, healthcare, energy, construction, and various other industries use digital data to create sustainable societies. The need for advanced materials in these fields will only expand in the future. In addition, rising geopolitical risks have accelerated the development of renewable energy and storage batteries. Against this backdrop, the JX Metals Group aims to contribute to developing a sustainable society through advanced materials.

By pivoting from an equipment industry company to a technology-based company, we will contribute to the creation of a sustainable society as a leader in semiconductor and ICT materials

Position Focus Businesses as the core of our growth strategy

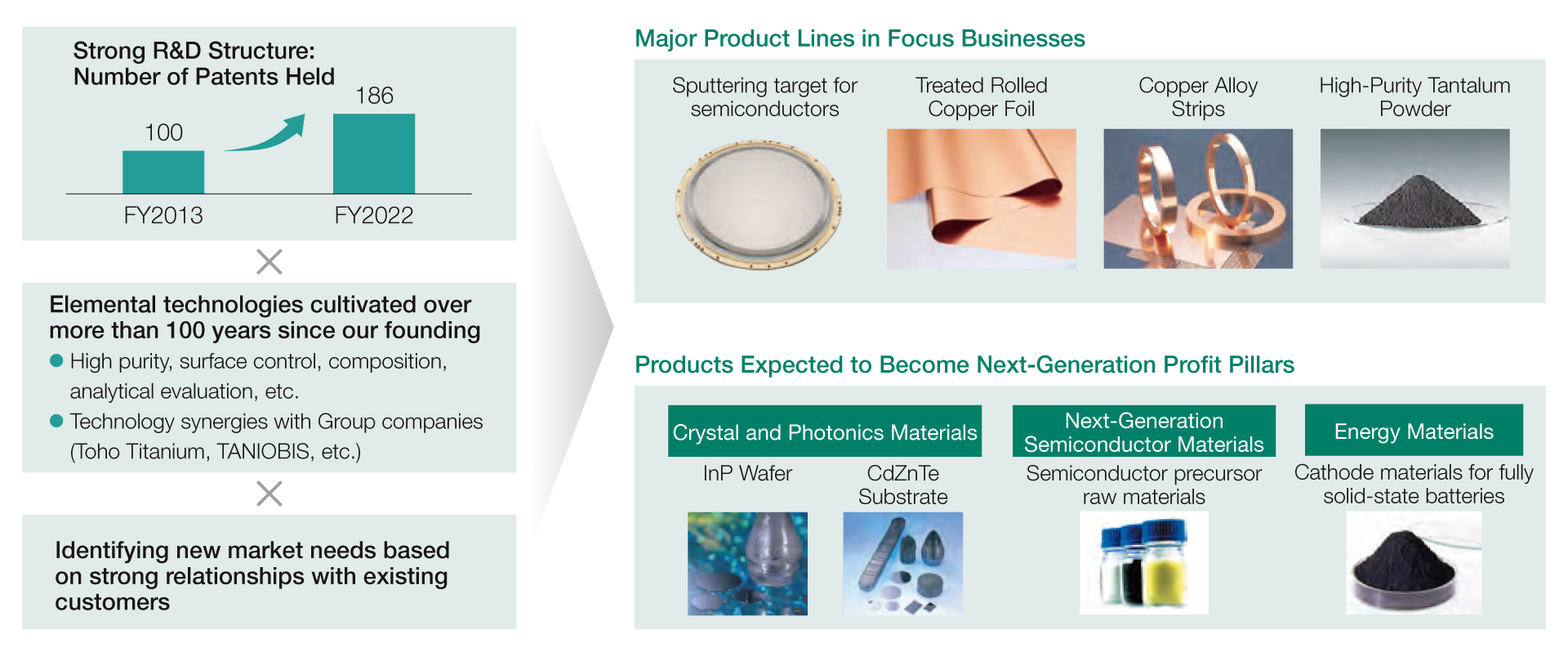

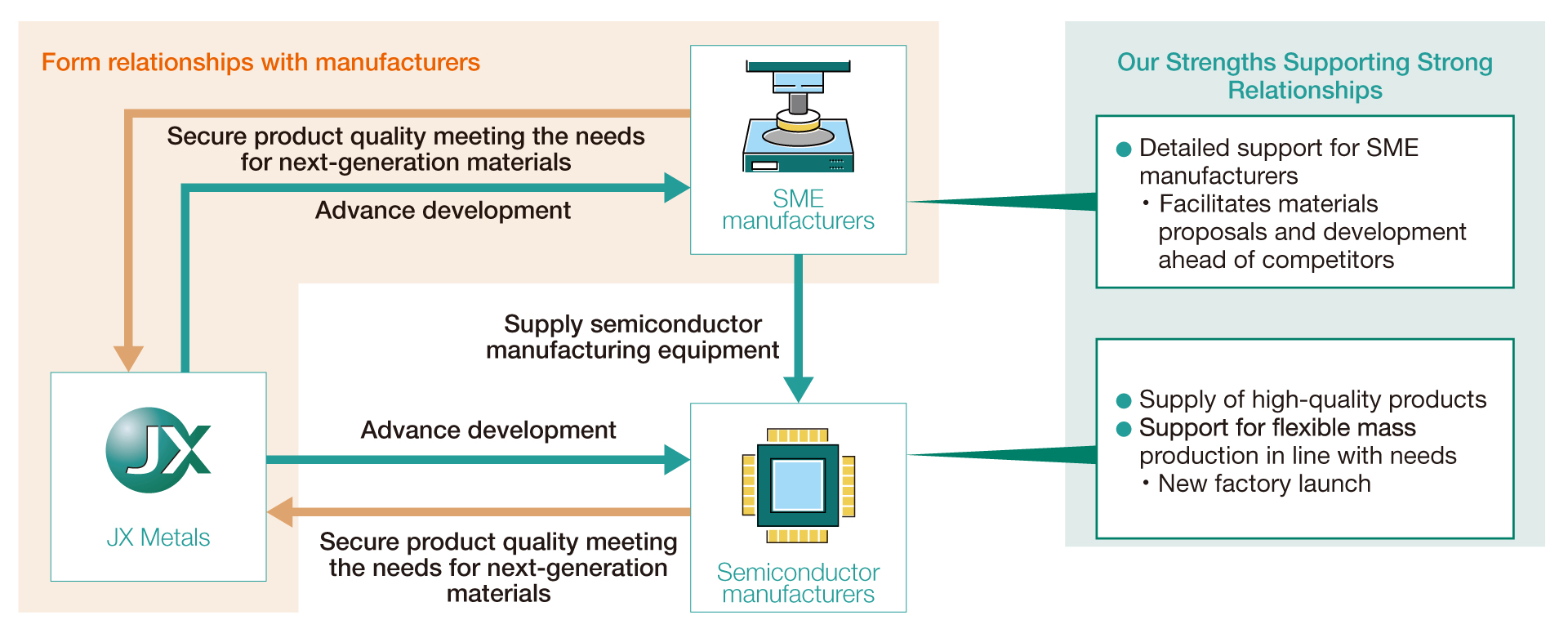

The JX Metals Group pursues the development of niche top in line with next-generation trends, leveraging a robust R&D structure and elemental technologies cultivated over more than 100 years since our founding. We also endeavor to identify new market needs based on strong relationships with customers.

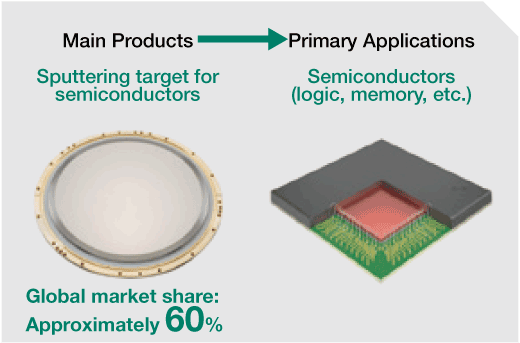

We offer a variety of sputtering targets for copper, tantalum, titanium, tungsten, cobalt, and more. We produce high-quality products in a stable manner using high purity and other advanced technologies cultivated through our business activities over many years.

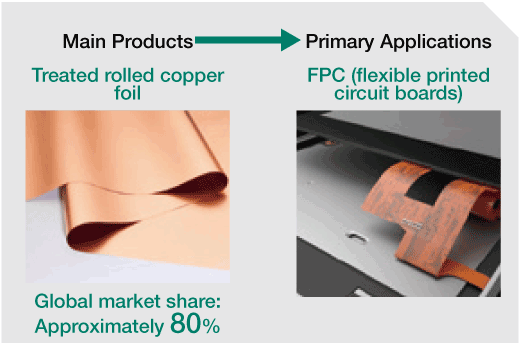

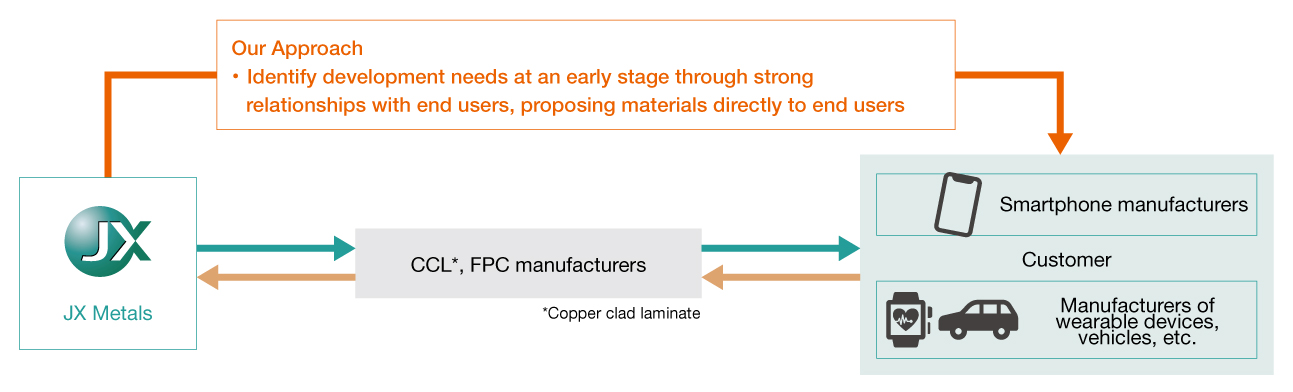

Treated rolled copper foil is used in flexible printed circuit boards (FPC). This copper foil is a wiring material that can be bent to connect components inside smartphones, contributing to miniaturization and longer life. We secured our position as a 1st vendor, maintaining a competitive advantage through a market development approach that allows us to launch products ahead of competitors by identifying development needs quickly based on strong relationships with end users.

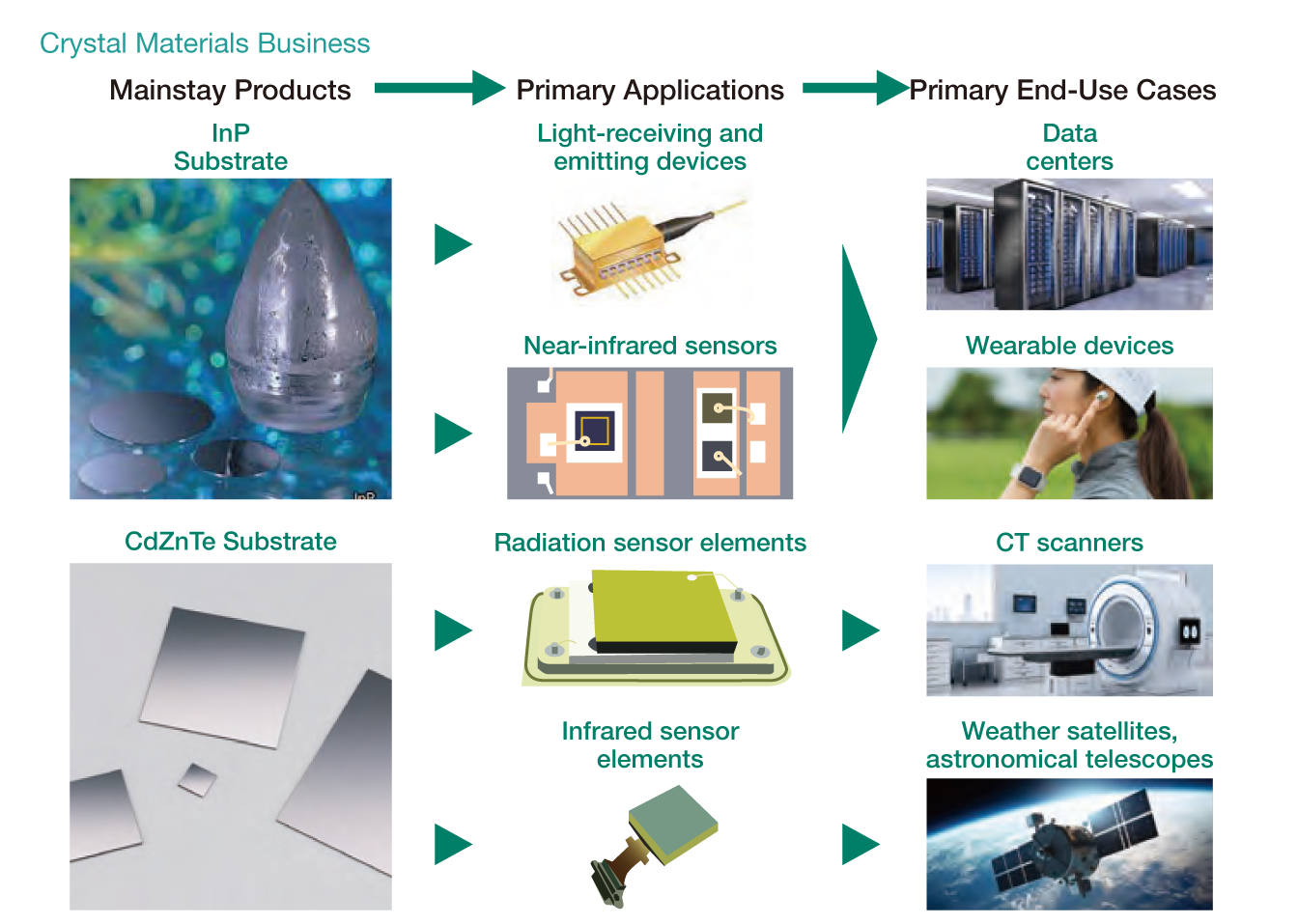

The spread of the 5th generation mobile communication system (5G) is expected to usher in an advanced digital society in which everything around us is connected to the network. We expect the market for InP Wafer used in data centers and CdZnTe substrates used in radiation and infrared detection applications to expand further in the future. The JX Metals Group pursues activities to create a product line that will become a third pillar beside our sputtering target for semiconductors and treated rolled copper foil.

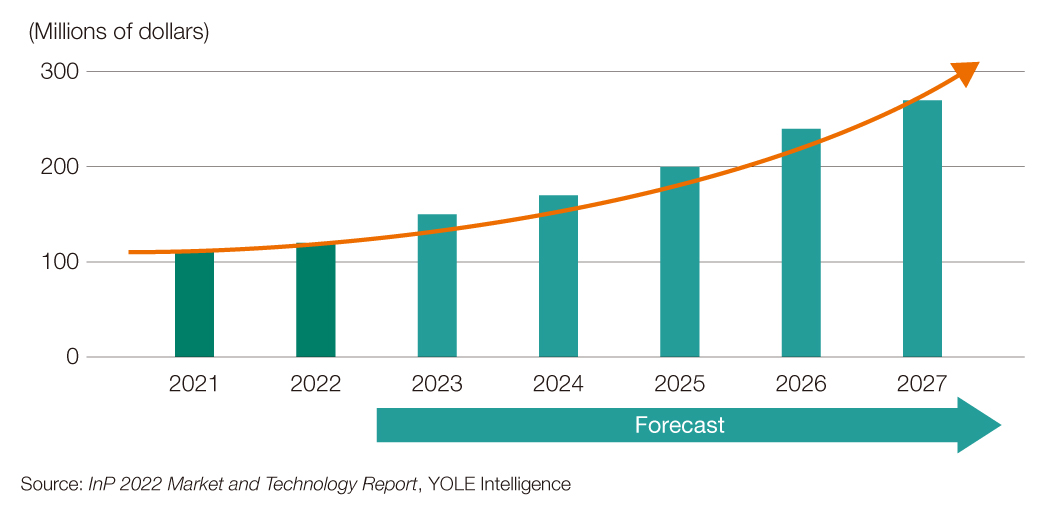

Demand for InP substrates, a crystal material we sell, is increasing for use in data centers and wearable devices. The market is expected to grow at an annual rate in excess of 16% between fiscal 2021 and fiscal 2027.

In anticipation of future growth in demand for semiconductor and ICT materials, the Group is expanding production capacity actively in Japan and overseas. Hitachinaka City, Ibaraki Prefecture, is the center of this expansion.

Rendering of the new factory in Hitachinaka

In March 2022, we acquired a large site in Hitachinaka City, Ibaraki Prefecture, launching construction of the Hitachinaka New Plant (tentative name), which will serve as our new central base. In addition to growth areas such as sputtering targets for semiconductors and treated rolled copper foil, the new factory will be responsible for advanced materials production and other new businesses, looking further ahead beyond 5th-generation mobile communication systems (5G).

We held a groundbreaking ceremony in January 2023 attended by Ibaraki Prefecture Vice Governor Yokoyama Yukinari, Hitachinaka City Mayor Ohtani Akira, and many other local well-known persons. The new factory is scheduled to begin operations in fiscal 2025, eventually employing more than 500 people, which is highly anticipated to contribute to the development of the local economy. In addition to achieving the Group vision, we aim to make the factory suitable for playing a part in increasing the presence of Ibaraki Prefecture and Hitachinaka City as a global supply base for advanced materials.

Commemorative photo at the groundbreaking ceremony

| Location | Shinko-Cho, Hitachinaka City, Ibaraki Prefecture |

|---|---|

| Area | 240,000m² |

In January 2023, we signed a comprehensive cooperation agreement with Hitachinaka City in connection with the construction of a new factory. Our hope is to serve as a member of the local community, sharing in the development of Hitachinaka City.

In addition to job creation and industrial promotion through the new factory, we intend to support various activities for the future of the community through a 100 million yen donation leveraging the corporate version of the hometown tax donation program. These activities include support for the operation of a community center in the Ajigaura district, where the new plant is located, as well as programs to foster the next generation.

Regional Cooperation in Ibaraki PrefectureJX Metals was founded in Hitachi City, Ibaraki Prefecture. Here, we are building two new factories to manufacture sputtering targets for semiconductors and treated rolled copper foil.

Hitachi City, Ibaraki Prefecture, is home to our main base, Hitachi Works, where we engage in a variety of businesses that include the manufacture and processing of copper and other nonferrous metal materials, research and development, and recycling, which is essential for protecting the environment.

Construction of the new Hitachi Factory, which will manufacture treated rolled copper foil, is underway at an investment of 16 billion yen in the Shirogane district within Hitachi Works. Currently, we perform the final surface treatment for treated rolled copper foil at Hitachi Works. However, the rolling process is carried out solely at Kurami Works (Takaza-Gun, Kanagawa Prefecture). By installing a production line for the rolling process at the new factory, we expect to increase production capacity by 25% compared to fiscal 2020 and strengthen our BCP* structure.

New Hitachi Factory

| Location | Shirogane-Cho, Hitachi City, Ibaraki Prefecture |

|---|---|

| Site Area | 8,001.77m² |

| Products | Treated rolled copper foil |

| Employees | 20-25 (plan) |

| Operation Launch | FY2024 (plan) |

The new Hitachi-kita Factory will manufacture sputtering targets for semiconductors. Now under construction, the factory represents a 14 billion yen investment located in an industrial park in the northern part of Hitachi City.

In December 2020, we announced a plan to increase production capacity for sputtering targets for semiconductors by 30% compared with fiscal 2020. As the semiconductor industry continues to grow beyond expectations, we announced a plan to invest a total of 32 billion yen and increase production significantly by 80% compared with fiscal 2020. The construction of the new Hitachi-kita Factory is part of this effort. This factory will be responsible for melting and rolling processes of sputtering targets for semiconductors.

New Hitachi-kita Factory

| Location | Sunazawa-Cho, Hitachi City, Ibaraki Prefecture |

|---|---|

| Site Area | 23,348.04m² |

| Products | Sputtering targets for semiconductors |

| Employees | 30-40 (plan) |

| Operation Launch | FY2024 (plan) |

| Installed Equipment | Melting and rolling equipment for sputtering targets for semiconductors (plan) |

JX Nippon Mining & Metals USA, Inc. is located in Arizona, the center of the semiconductor industry in the U.S., and is responsible for the downstream processing of sputtering targets for semiconductors. Under this business, we purchased land of 260,000m² (six times the current land used) and began construction of a new factory. In October 2022, we held a groundbreaking ceremony at the planned site of the new factory in Mesa. The ceremony was attended by many people, including government officials and local media.

By securing a sufficiently large site in Arizona, an area of growing concentration in the semiconductor industry, we plan to expand production capacity for sputtering targets for semiconductors further and meet customer needs in a flexible manner. First, we plan to construct new manufacturing facilities scheduled to start operations in or after fiscal 2024. The new factory will not only be a base for sputtering targets for semiconductors, but also a site for new business development, making it a center for advanced business fields in North America.

Rendering of the new factory

Sandra Watson, Arizona Commerce Authority president and CEO

John Giles, mayor of Mesa

Kuwabara Masago, president & CEO, JX Metals USA, Inc.

Pursuing innovation in nonferrous metals, the JX Metals Group strives to co-create new business with partners across a wide range of fields, focusing on advanced materials and highly functional and multifunctional materials. As part of our efforts, we concluded a comprehensive cooperation agreement with the Ibaraki University College of Engineering in July 2023.

Our main objective in this agreement is to develop human resources who will be active in Ibaraki Prefecture and contribute to the development of the region. We plan to expand the number of students hired from the university by establishing a new course for Ibaraki University students in our internship program. We also plan to conduct tours for College of Engineering faculty members to explore the possibility of joint research. Through the framework of this comprehensive cooperation agreement, we will pursue the development and hiring of the next generation of engineering personnel and potential joint research projects for further innovation.

Pursuing Open Innovation

Cooperation agreement signing ceremony