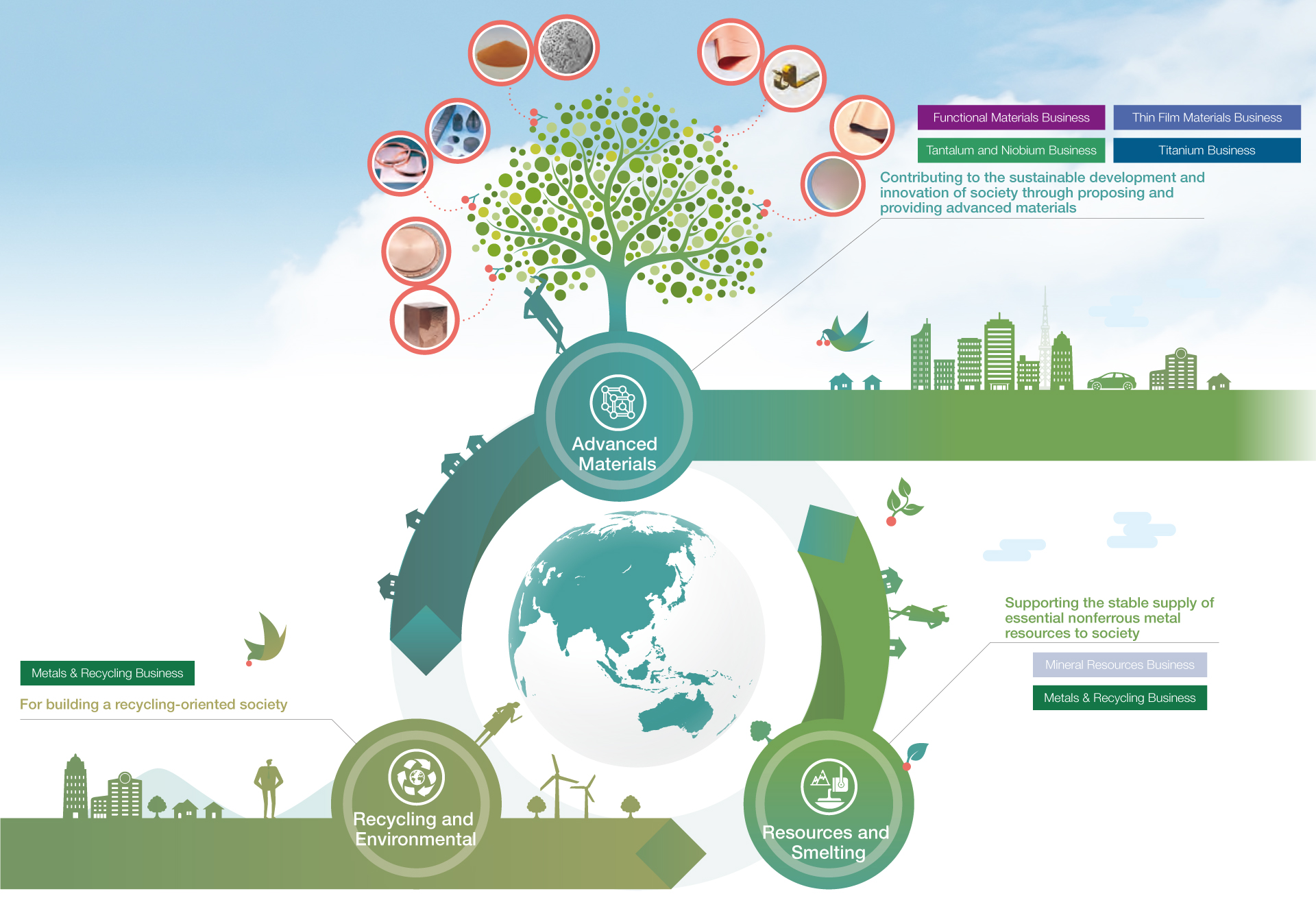

The Group’s strengths lie in its integrated value chain from upstream nonferrous metal material processes–resource development and smelting–to downstream advanced materials processes–manufacturing and development–and even recycling used electronic devices. Furthermore, in each of our businesses, we are constantly in pursuit of innovation in resource and material productivity and working to create new value.

Our outstanding production and quality control systems, as well as our advantageous integrated production capabilities, mean our treated rolled copper foil products boast superior flexibility, thermal resistance, strength, conductivity, and more.

The key factor for sputtering targets for semiconductors is a high degree of purity; JX leverages its highly stable processes to provide these targets, whether in mass production or special development.

TANIOBIS GmbH is a core supplier of high-purity tantalum powder, used in applications such as high-capacity miniaturized tantalum capacitors. In this way, we contribute to the miniaturization of smartphones, computers, and other electronic products.

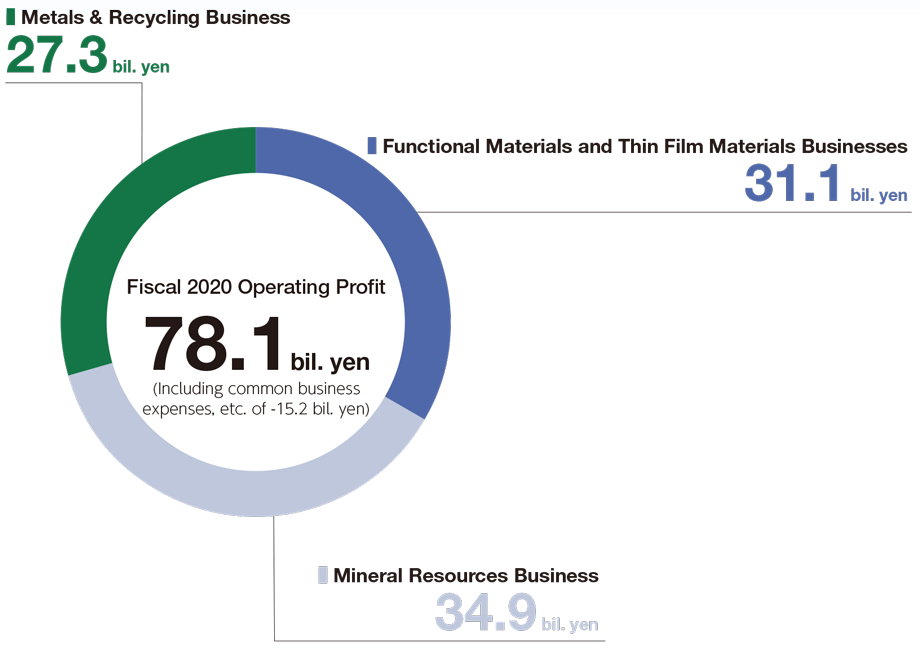

The Mineral Resources Business is actively involved in promising mine development projects as early as planning stages, contributing greatly to the stable supply of copper resources to Japan.

We use a large-scale copper smelting process to efficiently refine and recover gold, copper, and other nonferrous metal components from copper concentrate and recycled raw materials. By providing a stable supply of high-quality metals and creating a recycling-oriented system worldwide, we are contributing to the creation of a sustainable society.

Toho Titanium Co., Ltd. Manufactures titanium sponge by adding its own unique technology to the Kroll process, a method for reducing titanium tetrachloride with metal magnesium.