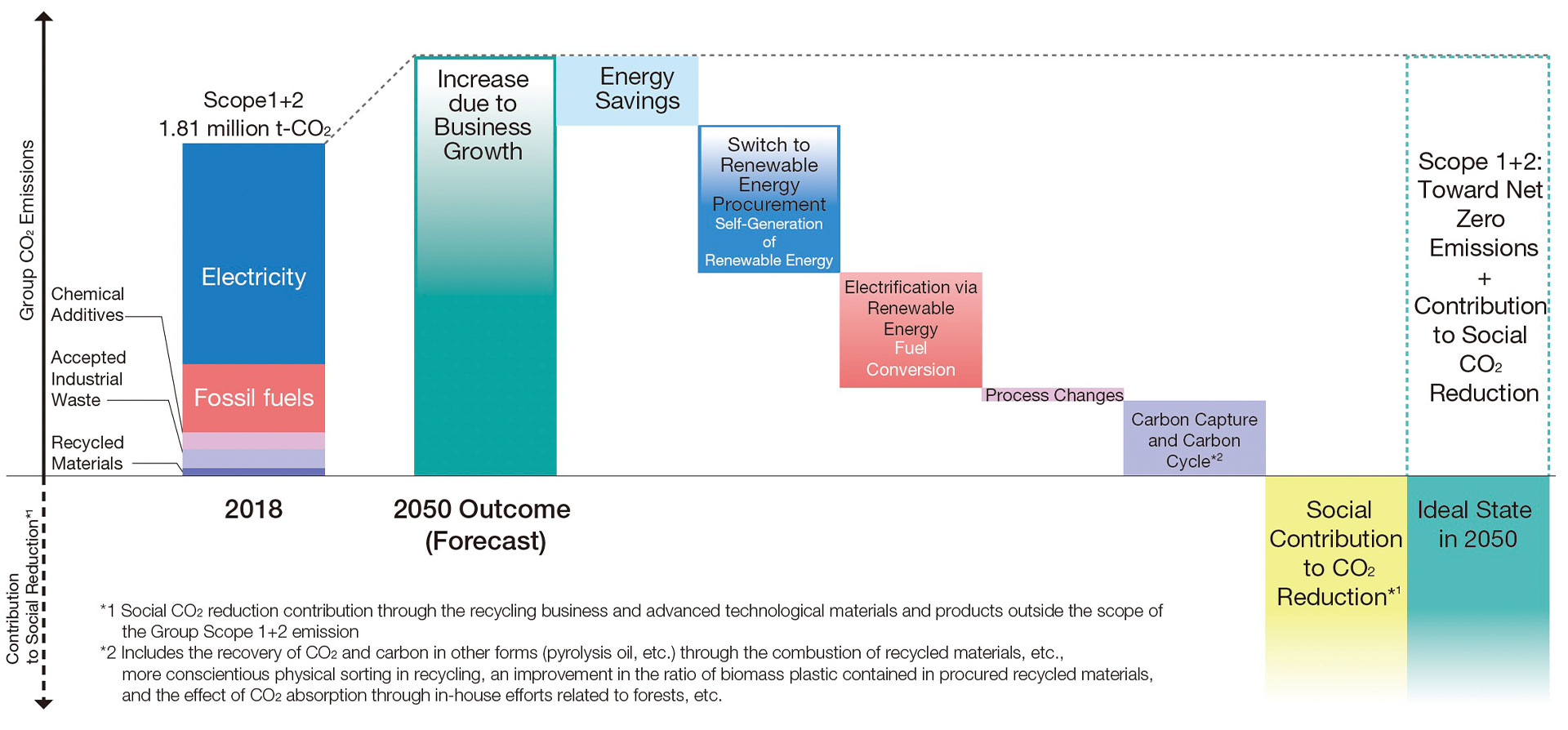

The world is waking up to the risk of climate change. More companies and countries are making prominent moves toward decarbonization. The JX Nippon Mining & Metals Group has declared that we will achieve net zero CO₂ emissions by fiscal 2050. And to this end, we have embraced a group-wide challenge to demonstrate leadership in decarbonizing the nonferrous metals industry.

In response to the worsening problem of climate change, our group was among the first to participate in the Keidanren Challenge Zero decarbonization project, launched in 2020. Under our Long-Term Vision, we established a target of 50% in total CO₂ emissions reductions by fiscal 2040 (compared to fiscal 2018). Our ultimate goal is net zero CO₂ emissions by fiscal 2050. However, recognizing the need to accelerate our efforts in line with social trends, in April, we moved up the timeline for our interim reduction target of 50% by 10 years to fiscal 2030. We made a formal announcement of this policy change in May 2021.

In January 2021, we launched the Carbon Free Project (CFP) with more than 60 members. The team consists mainly of individuals from our ESG Promotion Department, Facilities Engineering Department, and Procurement Department. To reach this major goal of net zero CO₂ emissions, we must focus on zeroing out activities, rather than merely extending past reduction activities. The CFP is responsible for pursuing company-wide CO₂ reduction activities by prioritizing activities over the long term. The CFP targets all energy- and non-energy-derived CO₂ emissions from our business activities, and we have formed working groups for each category to consider specific measures.

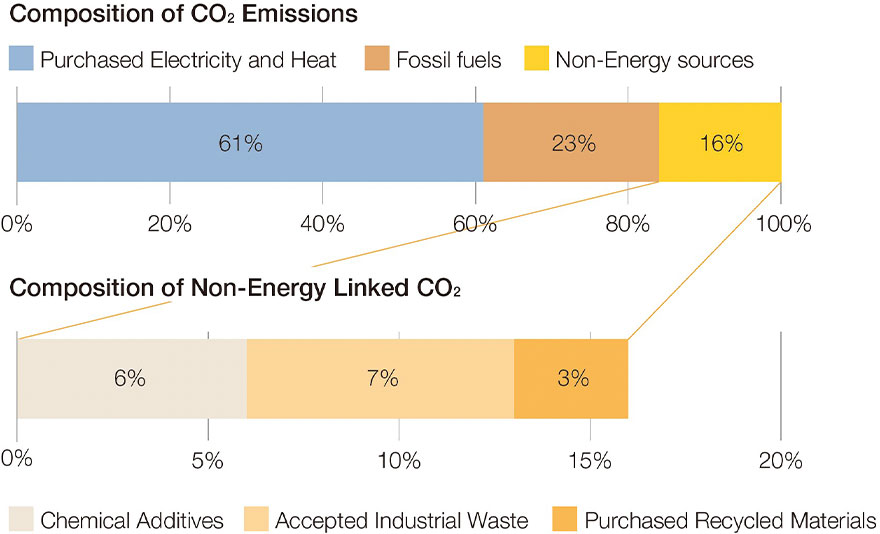

Approximately 80% of the total group CO₂ emissions are energy-linked emissions from electricity and fossil fuels. The remaining 20% comes from non-energy sources, including emissions from purchased recycled materials and accepted industrial waste, as well as chemical additives used in our processes.

Of the group’s total CO₂ emissions, 61% stem from electricity used in mines, manufacturing plants, factories, and similar facilities. This is a significant amount of CO₂ emissions for which we must take action if we are to achieve net zero CO₂. Accordingly, we have adopted CO₂-free electricity* as a major initiative in fiscal 2020.

In January 2021, we completed the conversion of the Caserones Copper Mine, which accounts for approximately 20% of group electricity consumption (as of 2018), to 100% CO₂-free electricity. In addition, we have made progress in making the switch at major domestic and international locations, including the Isohara Works, the Kurami Works, and Saganoseki Smelter & Refinery of JX Metals Smelting Co., Ltd. We plan to convert every group operating location to CO₂-free electricity as quickly as possible. We do acknowledge, however, that we must address certain issues in moving forward, including insufficient supplies of renewable energy and frequent systems updates.

* CO₂-free electricity: Electricity generated from methods that do not emit CO₂, rather than the generation of electricity that relies on the burning of fossil fuels or other methods that produce CO₂. CO₂-free electricity includes electricity generated by atomic power, as well as renewable energy from water, wind, and solar.

Caserones Copper Mine

| Switchover Period | Location | Business Area |

|---|---|---|

| June 2020 | Kasuga Mines Co., Ltd. | Mineral Resources Business |

| January 2021 | Caserones Copper Mine | Mineral Resources Business |

| Goslar Works, TANIOBIS GmbH | Tantalum and Niobium Business | |

| April 2021 | Kurami Works, JX Nippon Mining & Metals Corporation | Functional Materials Business |

| Isohara Works, JX Nippon Mining & Metals Corporation | Thin Film Materials Business | |

| May 2021 | Tsuruga Plant, JX Nippon Mining & Metals Corporation | Metals & Recycling Business |

| June 2021 | Saganoseki Smelter & Refinery, JX Metals Smelting Co., Ltd. | Metals & Recycling Business |

| July 2021 | Tatebayashi Works, JX Metals Precision Technology Co., Ltd. | Functional Materials Business |

| October 2021 (Scheduled) |

Hitachi Works, JX Nippon Mining & Metals Corporation | Metals & Recycling Business, Functional Materials Business, etc. |

| Mito Plant, TANIOBIS Japan Co., Ltd. | Tantalum and Niobium Business |

The switchovers in electricity identified above will amount to approximately 560,000 tons in CO₂ reductions (vs. Fiscal 2018).

Kurami Works, JX Nippon Mining & Metals Corporation

Saganoseki Smelter & Refinery, JX Metals Smelting Co., Ltd.

Many countries have established high targets for renewable energy generation, increasing the number of power-generation facilities. Japan has also announced its stance to increase the ratio of renewable energy significantly. However, this volume of renewable energy will not be sufficient to achieve carbon neutrality for Japanese society as a whole.

The JX Nippon Mining & Metals Group is expanding beyond the procurement of CO₂-free electricity, looking to generate and use renewable energy on our own. We have already adopted hydroelectric, binary, and solar power generation facilities at operating locations in Japan and overseas. In the future, we plan to leverage PPA*1 to generate electricity on-site within our facilities. We also intend to develop off-site electricity through self-consignment*2, sending electricity generated from one group location to other locations. In these and other ways, we will expand our use of renewable energy.

*1 PPA: Power Purchase Agreement. A system whereby a company or other facility owner leases space on its premises or roof for an electric power company to install a solar power generation system. The facility owner uses and pays for the power generated.

*2 Self-consigned transmission: A system in which electricity generated at a company’s own power plant in a remote location is transmitted to other JX Nippon Mining & Metals Group facilities through the power transmission and distribution network.

Solar panels at the Kakegawa Works of JX Metals Precision Technology Co., Ltd. (Shizuoka Prefecture)

(Thousands of kWh)

| Kakinosawa Power Plant, JX Nippon Mining & Metals Corporation | Hydroelectric | 27,067 |

| Kakegawa Works of JX Metals Precision Technology Co., Ltd. | Solar | 683 |

| Shimoda Hot Springs Co., Ltd. | Binary | 583 |

| Nikko Metals Taiwan Co., Ltd. | Solar | 234 |

The JX Nippon Mining & Metals Group operates in an industry that consumes enormous amounts of electricity. Although we pursue energy-saving activities at every stage of our business, we understand that we must engage in zero energy loss activities from new perspectives, if we are to achieve net zero CO₂. For example, we have invited ideas from the CFP and other group employees to help us achieve zero energy loss. Ideas have included updating facilities beyond the perspective of cost reduction to include CO₂ reduction and conducting bottom-to-top reviews of our facility operations.

The ENEOS Group launched a proof-of-concept to visualize fixed CO₂ in idle forests around former mine sites owned by JX Mining & Metals Corporation. The project, designed to promote CO₂ absorption and fixation in forests, is being conducted in collaboration with forest systems development company woodinfo. The project utilizes measurement technology and analysis data gathered via 3D lasers and drones to monitor and provide visibility to CO₂ fixation. We are participating in this project as part of our efforts to convert our idle and closed mining areas throughout Japan into ESG assets.

The business processes of the JX Nippon Mining & Metals Group use heavy oil and other energy sources besides electricity. We also use coke as a reducing agent. We will take measures to reduce CO₂ emissions from these energy sources and materials. One such measure is fuel conversion. In the industrial world, technologies for new fuels such as hydrogen and ammonia are being developed for decarbonization. We intend to study the full-scale use of such fuels in our businesses.

CO₂ emissions from the metal smelting process, which is a key part of the group value chain, account for a relatively large portion of our total emissions. To decarbonize the smelting and refining process, the CFP and the Advanced Technology & Strategy Department have begun to work together in drawing a development roadmap.

Toho Titanium Co., Ltd., which is in charge of the Titanium Business, is taking on the challenge of developing a new titanium smelting method that emits virtually zero CO₂. This method is simpler than the current Kroll process and emits no CO₂ directly from the manufacturing process. Not only that, but the new method also reduces power consumption significantly, and is expected to decrease CO₂ emissions from electricity generation by a considerable margin. Toho Titanium Co., Ltd. will conduct a pilot test at its Chigasaki Plant beginning in fiscal 2021, aiming to commercialize the technology by fiscal 2025. Leveraging this technology and other measures, the company will seek stronger cooperation among supply chain partners to reduce CO₂ emissions, aspiring to net zero CO₂ emissions by 2050.

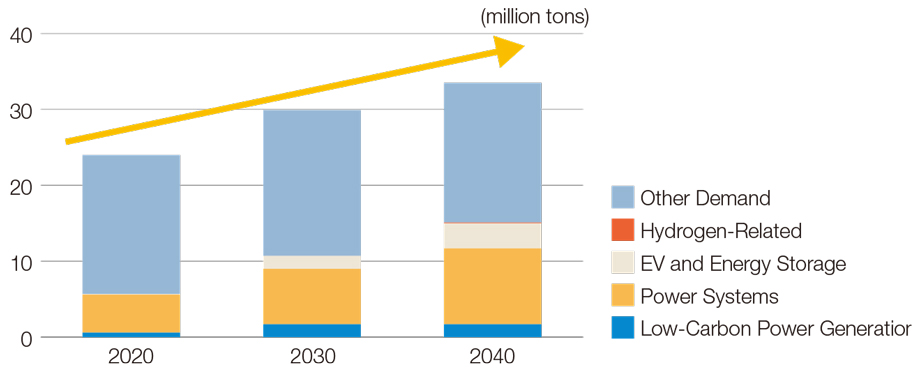

The JX Nippon Mining & Metals Group believes that we have an important mission to not only eliminate CO₂ emissions through our business activities, but also contribute to the creation of carbon-neutral societies through our products and services. We have supplied copper to societies since our inception. Copper is a vital material that acts as the blood vessels for energy in supporting carbon-neutral societies. This is due to the particularly excellent electrical conductivity of copper as compared to other metals, as well as the fact that copper can be recycled without a degradation in quality. We expect demand for copper materials to increase as renewable energy sources and electric vehicles become more widespread. In addition, the semiconductor component materials and various high-performance alloy materials produced by our group are essential raw materials for electronic devices and batteries used to control, store, and generate renewable energy. The innovative electronic devices developed using our advanced materials are expected to make a significant contribution to the progress of decarbonization through the digital transformation of society.

At the same time, it is important to stabilize the supply of various materials experiencing rising demand to avoid supply constraints and barriers to decarbonization. In this context, the resource and recycling businesses of the group are very important. The JX Nippon Mining & Metals Group will continue to play a role in the stable supply of materials, finding greater efficiencies in our production processes, making greater gains in energy- saving performance, and expanding the use of recycled materials.

⇒ See Special Feature 2 for details on how we are strengthening recycling and engaging in other initiatives.

(Source) The Role of Critical Minerals in Clean Energy Transitions (SDS scenario); IEA

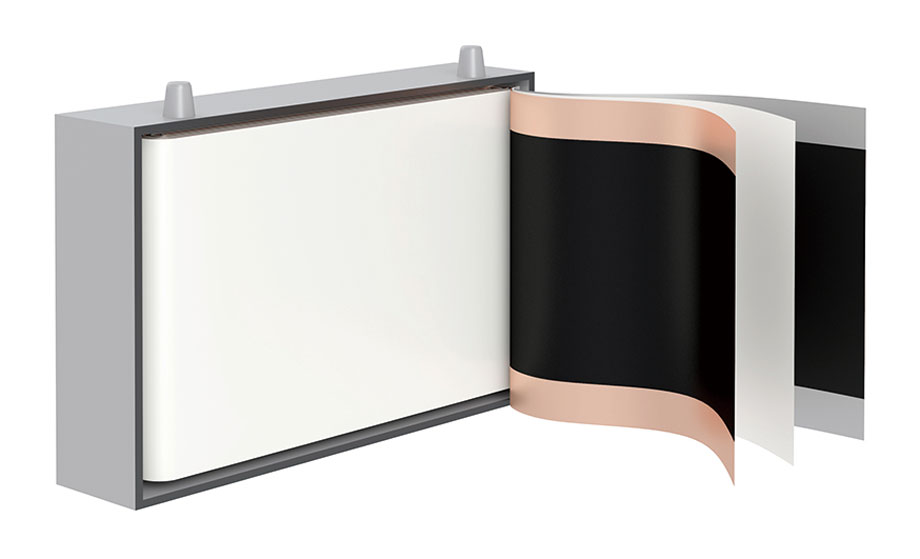

Examples of Products Supporting Carbon-Neutral Societies: High strength rolled copper foil for special Li-ion batteries

Suwabe Takeshi

Executive Officer, General Manager of the ESG Promotion

Department, and General Manager of the Planning & Coordination Department

JX Nippon Mining & Metals Corporation

Among the many initiatives in ESG management, addressing climate change, particularly concrete actions toward decarbonization, has become the most important issue. In January 2021, we launched a company-wide project to achieve net zero CO₂ emissions by 2050.

We believe the key to our activities is whether we can work toward net zero on a sustained basis over the long term. For this reason, we began by holding seminars with experts to create a deeper awareness of the necessity for decarbonization. We asked the attendees to work with their departments in formulating a roadmap to zero emissions across a wide range of areas. These areas included energy conservation, CO₂-free power procurement, in-house power generation, fuel conversion, and process innovation. We also discussed how to proceed over the long term based on these roadmaps. To press forward in these challenges, including the adoption of new ideas, we set up an ESG investment framework, defining environmental improvements in terms of monetary value as well. In parallel with these activities, in only the first six months of this project, we already announced a policy to switch to CO₂-free electricity at all operating locations. This policy demonstrates the seriousness with which we are approaching decarbonization as a company. We also announced that we moved up our target for achieving a 50% reduction in total CO₂ emissions by 10 years, from 2040 to 2030.

Moving forward, we will consider how to harmonize our project with other ESG issues. We are a nonferrous metals manufacturer with our own vertical supply chain. This means we are in a position to solve issues in a variety of areas such as the creation of recycling-oriented societies and coexistence with local communities, while still maintaining the line toward decarbonization. We are already working to encourage recycling, and we intend to contribute to local communities through the generation of renewable energy.

The year 2050 may sound far away. And it is true that many initiatives must wait for technological progress and infrastructure development. Nevertheless, we are determined to face the issues of climate change and decarbonization head on. We will accelerate our activities toward net zero emissions through the steps we can take at present, while also adopting and creating new technologies.