It is essential for companies to gain and maintain stakeholder trust to conduct business and increase long-term corporate value in a drastically changing society. The Group promotes strict compliance with laws and risk management to increase the soundness and transparency of management and reinforce governance.

Assessment: Achieved/Steady Progress Not Achieved

| KPI | Fiscal 2021 Results/Progress | Assessment |

|---|---|---|

| Steady operation of Enterprise Risk Management (ERM) | The Group bases its activities in ERM concepts with reference to ISO 31000, a set of guidelines for risk management methods. In fiscal 2021, an external organization evaluated the ERM system and the status of its operations, and improvements were implemented to address the issues that were identified. |

|

| Compliance training tailored to business characteristics and social movements, etc. | The Group conducts compliance training every year to increase awareness and knowledge of compliance among executives and other employees. In fiscal 2021, in addition to annual the rank-specific compliance training, which is conducted every year, we held training programs in Japan and overseas regarding harassment and the Subcontract Act, tailored to business characteristics and social trends, and other factors. |

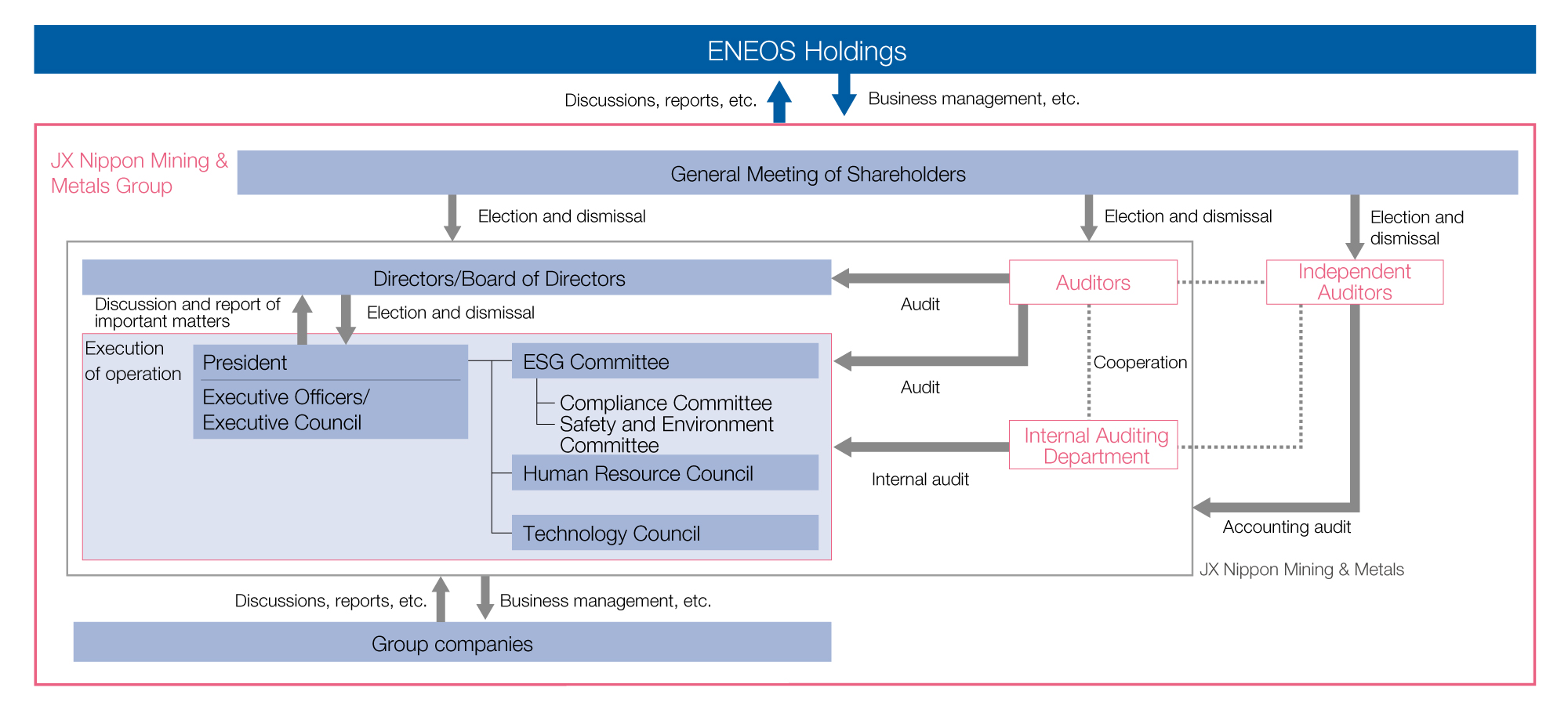

The Group is working to strengthen its governance structure in order to have a firm grasp on rapidly changing business environments, to accelerate decision-making and business execution, and to achieve fair and highly transparent management.

The Board of Directors was established to discuss matters specified by laws, regulations, and the Articles of Incorporation, as well as other important management issues. The Board of Directors is composed of the president and seven directors (as of June 2022) (six male directors, one female director). Auditors can also attend the meeting and express their opinions. In accordance with laws, regulations, and the rules of the Board of Directors, transactions involving conflicts of interest between directors and the Company are subject to approval by the Board of Directors.

As an advisory organ to the president, the Executive Council was established to discuss important matters regarding company management and to report the state of business execution. The Executive Council is composed of the president and executive officers designated by the President. Full-time Auditors can also attend the council meeting and express their opinions.

Company compensation for the executives consists of fixed monthly compensation based on the relevant individual’s role, and variable performance-based bonus payments. The bonus is determined by the consolidated business results of the Company as well as ENEOS Holdings. The Company does not have an executive officer retirement benefit program. The share-based payment system was implemented in July 2017. The share-based payment system applies the Board Incentive Plan (BIP) to Board Members, etc. to provide ENEOS Holdings shares according to individual role and performance as part of the incentives program.

Auditors attend Board of Directors meetings, Executive Council meetings and other important meetings of the Company to express their opinions as needed to increase the effectiveness of audits. In addition, auditors endeavor to understand the state of business execution by individual executives of the Company and the Group companies, through interviews, and through the inspection of documents. Furthermore, auditors also receive periodic reports on audit plans, progress, and results from the Internal Auditing Department and the accounting auditor while enhancing cooperation through the exchange of information and opinions.

With the recent growing calls from society to strength governance and internal controls, we appointed new outside directors in both April and June of 2022 in order to incorporate new perspectives in judgement and new stimuli. As well as provide an external oversight function. As of June 2022, three out of seven directors are outside directors.

Each Group company is placed under the jurisdiction of the appropriate operating or corporate department of the Company based on its business line, and the execution of its operations is managed and supervised by that department. Important matters regarding the business management of individual Group companies are reported to the Company through the relevant supervising departments. If necessary, they are also reported or discussed at the Executive Council and other important meetings.

The Group has established the Basic Policy for Establishment and Operation of Internal Control Systems and based on this policy, the Group has established internal control systems to ensure the efficiency and appropriateness of its operations. In addition to receiving reports on the status of internal control activities from each division of the Company, we conducted a survey of the status of development and operation of internal control systems at major Group companies. The status of the development and operation of internal control systems is, in principle, monitored once a year by the Executive Council. While taking into consideration the business characteristics of each company, we are continuously improving internal control systems for the Group as a whole.

We conduct internal audits across the entire JX Nippon Mining & Metals Group to investigate, discuss, and assess the state of business administration, operations, and asset preservation from the standpoints of legality, efficiency, and effectiveness. The Internal Auditing Department is in charge of these functions.

The Internal Auditing Department establishes a medium-term policy at three-year intervals and drafts auditing plans for each fiscal year to ensure systematic internal audits. Internal audits of Group companies are conducted in collaboration and cooperation with auditors dispatched from the Company. Based on the results of these audits, proposals for necessary improvements are made, with progress tracked for corresponding actions. Audit results and findings are reported to the president of JX Nippon Mining & Metals, to the relevant Group company, and, as necessary, to the Executive Council.

The JX Nippon Mining & Metals Group Code of Conduct and the JX Nippon Mining & Metals Group Compliance Regulations define compliance as not only observing domestic and foreign laws, rules, and regulations, but also acting in line with social norms and corporate ethics. We conduct our corporate activities with an emphasis on compliance. Based on the belief that thorough compliance is a prerequisite, the Group, as a member of the community, continues to create value in response to the expectations of its diverse stakeholders, and we have established various internal regulations concerning compliance. At the same time, we have established Compliance Priority Targets for each fiscal year and monitor the real-time status of their implementation. If any issues are identified in the system or in operations, we make improvements as we continue various efforts that will enable us to remain a trusted corporate group.

Measures related to compliance in the Group are determined at Compliance Committee meetings (twice yearly in principle). The Committee consists of executives from the Company and other major Group companies in and outside Japan. In response to reports on the state of compliance provided by individual departments of the Company and Group companies, the Compliance Committee evaluates the risk of fraudulent acts, legal violations, and other misconduct related to business operations, and reflects the results in setting priority issues and formulating education plans.

To increase reliability, we have outsourced the Group’s whistleblower program to an external organization. This external organization is responsible for accepting anonymous reports from whistleblowers. We have also taken a wide range of measures to increase awareness of the program throughout the Group. Such measures include displaying posters at individual Group company sites to publicize the program, posting articles in pocket editions of the Group Philosophy, which is distributed to all employees, opening a special section on the Company intranet, and introducing the program during compliance education sessions. In fiscal 2021, we received several reports through the program and took necessary measures in all instances in accordance with the relevant rules and regulations while taking due care to protect whistleblowers.

The Group has established a system for eliminating anti-social forces based on the JX Nippon Mining & Metals Group Regulations for Dealing with Anti-social Forces and the JX Nippon Mining & Metals Group Detailed Rules for Dealing with Anti-social Forces in order to cut off any relationship with anti-social forces. This system includes periodically conducting specified investigations of business partners and their related parties, and taking contractual measures in advance to terminate business relationships, depending on the circumstances. In order to prevent violations or suspected violations of anti-bribery laws and regulations by Group company executives and employees, we have established an anti-bribery system founded on the JX Nippon Mining & Metals Group Anti-Bribery Regulation. This system includes the requirement of a prescribed set of checks when providing entertainment, gifts, etc. to a public official or similar person, and approval from a responsible party when certain conditions are met. In fiscal 2021, we continued to check application based on the regulations, and confirmed that these were generally being applied properly. (There were no adverse dispositions issued by regulators in regard to bribery.)

The Group has established the Program for Compliance with Competition Laws, which includes rules such as those requiring all employees to report in advance planned transactions or gatherings with competitors to confirm that that they do not violate competition laws, requiring individual managers to submit periodic reports to the head office, and so on. In fiscal 2021, we continued to check application based on the aforementioned program, and confirmed that these were generally being applied properly. (There were no adverse dispositions issued by regulators in regard to anti-competitive behavior.)

We conducted complete inspections for compliance with environment and safety laws at 2 Group sites in fiscal 2021. We confirmed that environment-related and occupational health and safety-related laws were thoroughly understood by employees at all Group company sites and no serious lack of understanding was observed. All sites are also responding appropriately to matters requiring improvement.

We conducted inspections for compliance with personnel and labor laws at eight Group sites in fiscal 2021 and confirmed that they were properly managed.

The Group facilitates the fulfillment of compliance education to increase awareness and knowledge of compliance among executives and other employees, and conducts a variety of compliance and legal training sessions in Japan and, overseas based on business characteristics and social trends.

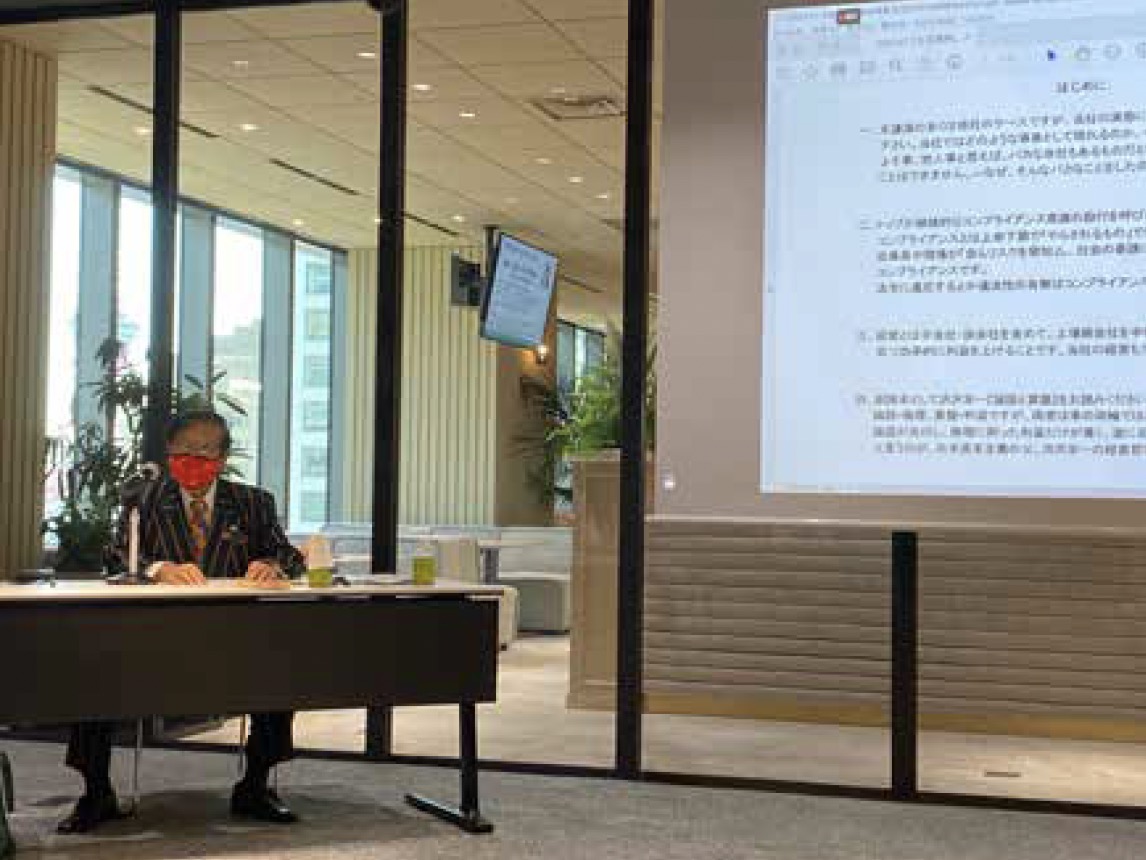

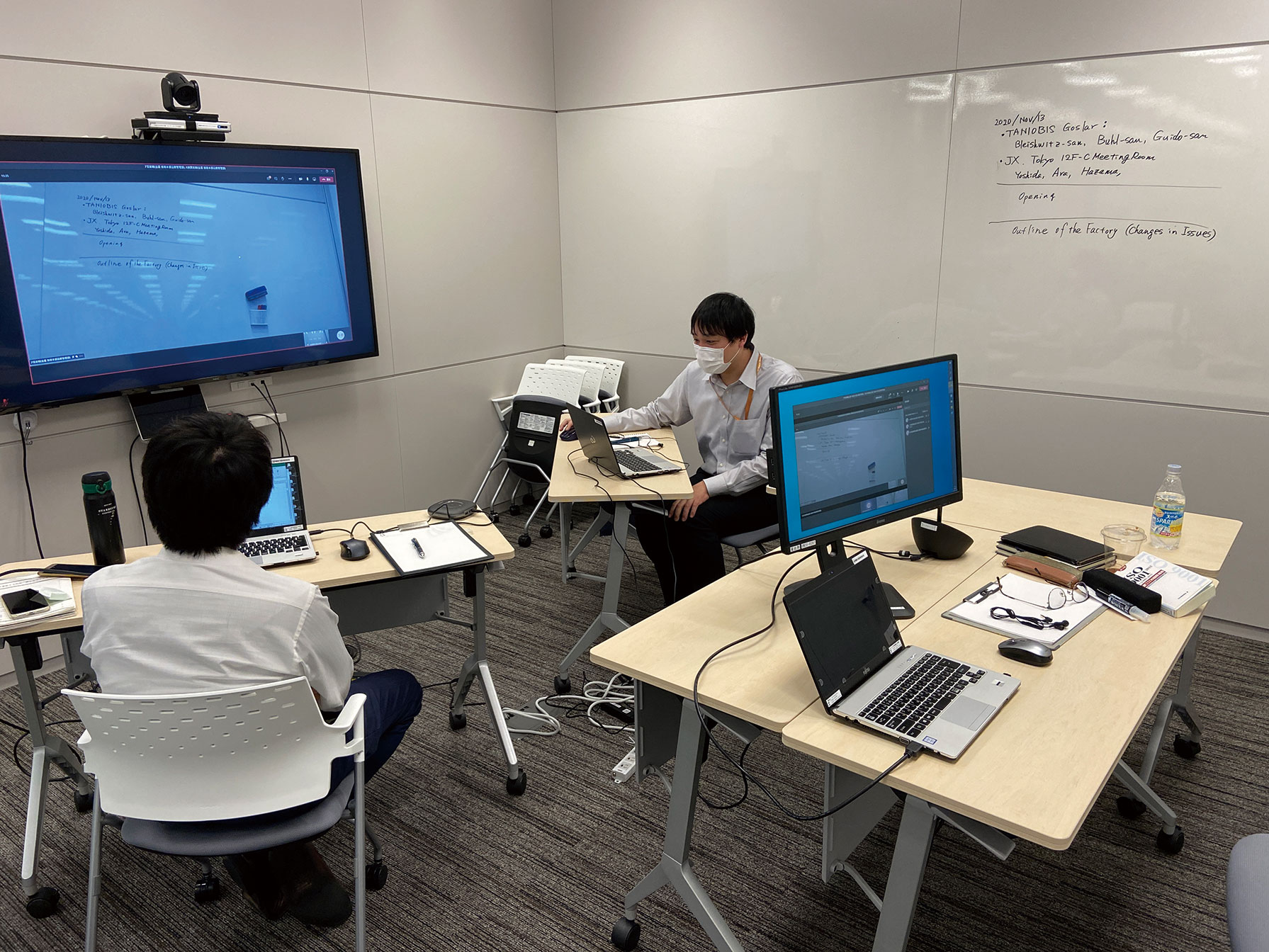

In fiscal 2021, in addition to annual rank-specific compliance training (for directors, managers, new employees, etc.) that is conducted every year, training sessions on internal controls, security trade controls, harassment, the Subcontract Act, Stamp Tax Act, etc. were conducted as theme-specific legal and regulatory education sessions. At overseas bases, we con-ducted education for expatriates at the headquarters or the bases, taking into account business characteristics and social trends, etc. In Germany and China, lectures on the Group’s compliance system and explanations of important laws and regulations, such as those dealing with competition law compliance and anti-bribery, were presented mainly to national staff managers by lawyers, legal staff, and other instructors. It was an opportunity for participants to deepen their understanding of compliance.

Going forward we plan to continue to studying and implementing compliance training programs in Japan and overseas, based on trends in legal revisions, regional characteristics, and other factors.

Compliance training for executives by Kubori Hideaki, attorney at law, Hibiya Park Law Office (Headquarters)

The JX Nippon Mining & Metals Group recognizes that the proper fulfillment of tax obligations in the countries and regions where a company does business is one of the most important social responsibilities that it should fulfill. Based on this, we are fostering awareness of tax compliance and working to maintain our tax governance system in accordance with the ENEOS Group Tax Matters Policy.

The Group recognizes that intellectual property rights are important company assets and strives to protect and utilize such rights. In addition, the JX Nippon Mining & Metals Group Basic Procurement Policy clearly states that we respect the intellectual property rights of other companies and endeavor to not infringe on them. In researching and developing new products and technologies, we conduct preliminary investigations to ensure that our products do not infringe on intellectual property rights.

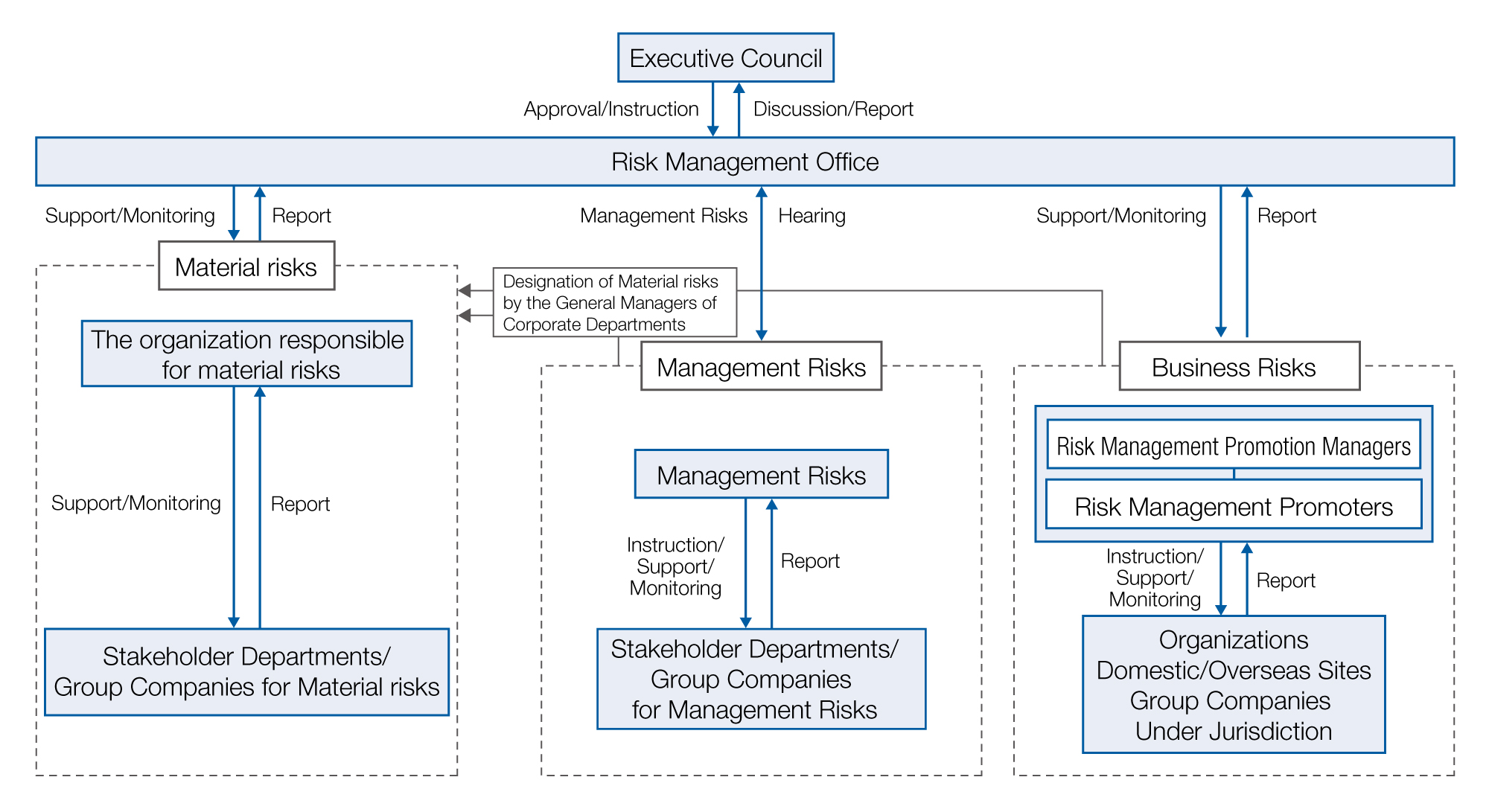

We identify, analyze, and assess various risks surrounding our business based on future projections and changes in the internal and external environment, and implement measures such as reducing, transferring, and retaking these risks. In addition, by monitoring the situation, we promote risk management in accordance with the following principles with the goal of appropriately managing risks and supporting the management of the Group.

At the Group, we select Material risks, approve response plans for each material risk, and monitor these plans, all with the approval of the JX Nippon Metals & Mining Executive Council. In addition, the Risk Management Office in the Company’s Administration Department is responsible for the overall risk management for both the Company and Group, handling ERM.

Risk is defined as “any uncertainty that may affect the management of JX Nippon Mining & Metals Group companies.” Here, in order to achieve risk management that is linked to our long-term vision, medium-term management plan, and business plan, we classify risks into “management risks” and “business risks.” Among those management risks and business risks, risks that we determine will have a significant impact on the Group’s management, and that should be addressed on a company-wide basis, are designated as “material risk s” by the Executive Council. These important risks include risks related to business continuity and sustainability, such as climate change and risks related to human rights. The organization responsible for material risks takes the lead in responding to these risks. In addition, the Executive Council monitors the status of these actions.

In fiscal 2021, in order to strengthen our risk management initiative, an external organization conducted an evaluation of our ERM framework and its operational status. We have also made improvements in response to the issues identified. We will continue to take risk management initiatives as we operate PDCA cycles within this mechanism. In this process, we will evaluate the appropriateness and adequacy of our risk management system, identify issues, and make continuous improvements.

Risk response is the assessment of risk and the selection and implementation of an appropriate response to that risk, and includes transfer, reduction, retention, or avoidance. For risks that could have a significant impact on our business activities despite our risk reduction measures, we will utilize insurance as a means of risk transfer to address the risk. The Risk Management Office has established uniform standards for insurance coverage to ensure that insurance is properly arranged and utilized. We will continue to review these standards as appropriate to ensure effective and precise risk transfer responses.

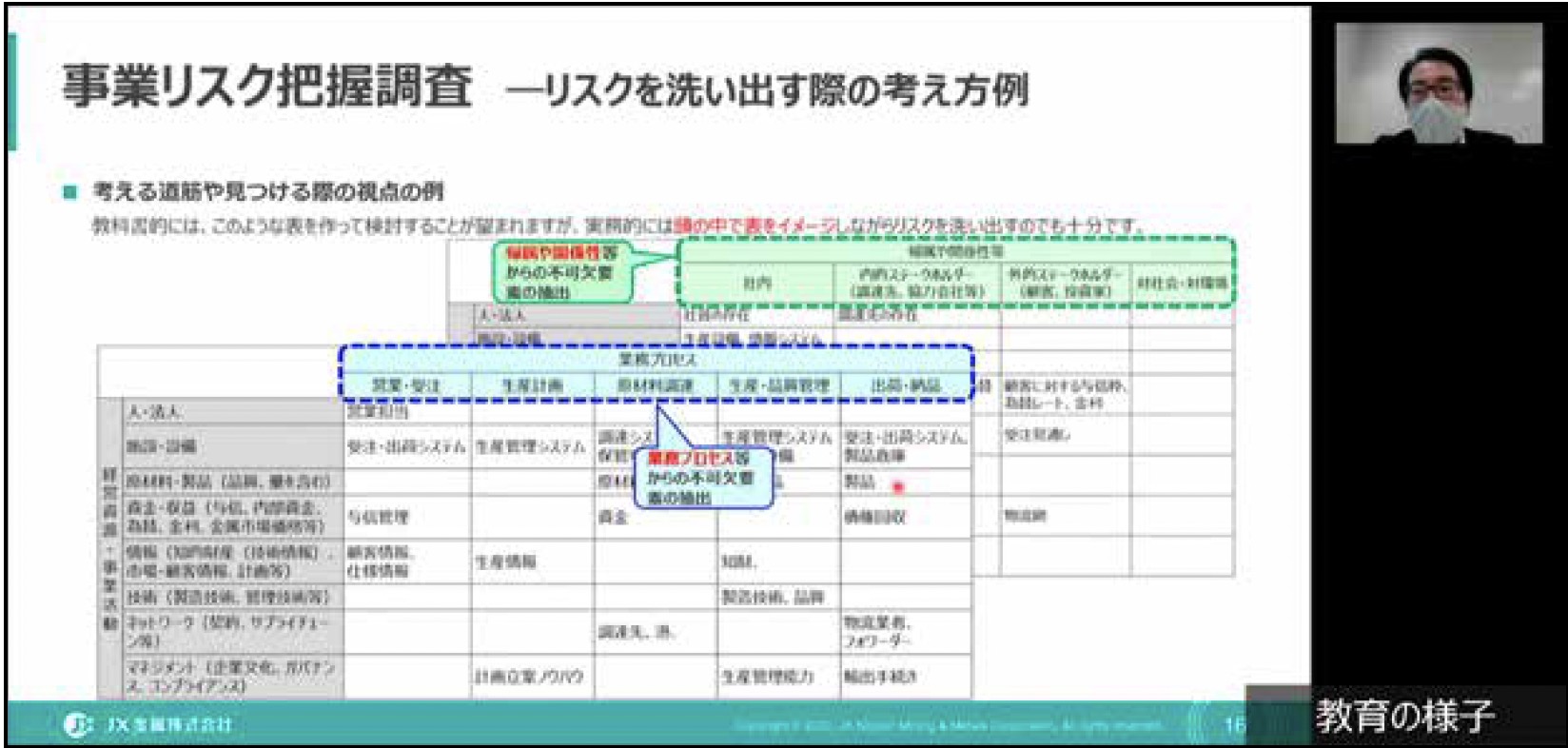

With the aim of increasing risk sensitivity, the Group conducts training for those responsible for and in charge of risk management promotion. For example, we share perspectives and case studies that are necessary to properly identify risks that may affect the achievement of each organization’s goals. In addition, we hold workshops on an ongoing basis to discuss measures to prevent the emergence of risks related to cross-divisional themes.

The Group has formulated business continuity plans (BCP*1) to minimize damage and achieve early recovery in the event of business interruption due to a major earthquake.

From fiscal 2020, we have taken this to a higher level and have begun working toward the establishment of an all-hazard BCP called a resource-based BCP. This is not a BCP for each event such as an earthquake or a flood, but one that focuses on resources (facilities, raw materials, materials, etc.) that are likely to disrupt business activities during emergencies, and organizes relevant disaster mitigation and recovery measures. In addition, we regularly survey the risk of disasters occurring where our major business sites are located to help us make decisions about preventing damage and investing in facilities. Through these efforts, we aim to further strengthen our BCPs. We also continue to further improve our initial disaster response.

In fiscal 2021, at the head office and other sites, we (1) the establishment of a disaster control headquarters, (2) the confirmation of employee safety, (3) the assessment of damages both inside and outside each company, and (4) the sharing and discussing of information, and initiation of measures. The exercise was carried out without disclosing the scenario. The Group endeavors to verify BCPs through periodical training and establish a Business Continuity Management (BCM*2) system for further improvement.

BCP training at the Head Office

Saganoseki Smelter & Refinery conducted a BCP training in October 2021, practicing improvement measures for issues that had emerged during the previous year’s training and discussing facility recovery plans. This time, we conducted a training exercise conducted for a tsunami caused by an earthquake and focused on verifying whether the new rules of conduct stipulated in the BCP document could be implemented without delay. It included the evacuation of employees and vehicles to higher ground and the establishment of a first-aid station.

The Saganoseki Smelter & Refinery is located in an area adjacent to the ocean and therefore faces a high risk of experiencing earthquakes and tsunamis. We will continue to make efforts to further strengthen our BCP system to ensure a stable product supply.

JX Metals Smelting Co., Ltd.

Administration Department, Saganoseki Smelter & Refinery

Iwai Koji

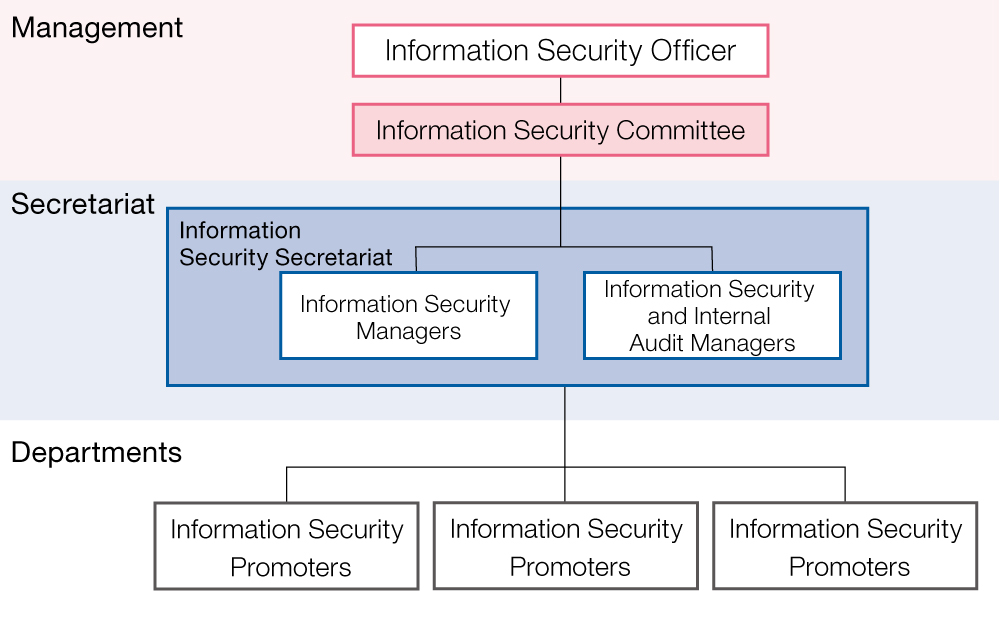

The Group has taken steps to build an information security management system (ISMS) in compliance with ISO 27001 from the three perspectives of strengthening information security compliance, increasing customer trust, and leveraging information internally and externally. In fiscal 2021, we conducted risk assessments and internal audits of information security in each department and made improvements based on the results of these assessments under the supervision of the Information Security Officer. We also further strengthened physical protection measures. In addition, in order to raise awareness of information security within the Group, we conducted rank-based training programs based on the newest information available, including training for members of management and training for general employees.

In upgrading information security, we will incorporate the cyber security measures implemented by the IT Department. At the same time, we will promote continuous improvement in accordance with ISMS in order to contribute to the realization of our long-term vision of becoming a technology-based company.

As a company with a social mission to provide a stable supply of nonferrous metals and advanced materials, the JX Nippon Mining & Metals Group recognizes that the information entrusted to us by our customers and business partners, as well as trade secrets and personal information held by us, are important assets. We have established a basic policy for information security in order to systematically and continuously strengthen information security.

The Group recognizes that its social mission is to provide a stable supply of nonferrous metals and materials in order to contribute to the sustainable development of society. Based on this policy, we aim to improve the level of quality control throughout the entire supply chain.

The JX Nippon Mining & Metals Group hereby sets forth, and acts in observance of, this Basic Quality Policy in order to contribute to the development of a sustainable society while recognizing that its social mission is to stably supply nonferrous metals and materials.

The Group has and operates a quality management system (QMS) to realize our Basic Quality Policy. We work to continually make improvements through steady PDCA cycles, aiming to realize better quality through the QMS. Company sites both in Japan and overseas have acquired QMS third-party certification (ISO 9001, etc.).

In addition, the Group reviews quality improvement activities and establishes action plans through the Quality Management Meeting, which is made up of top management. We also hold Quality Assurance Managers’ Meetings twice annually to share information on quality management. Participants share the action plans adopted at the Quality Management Meeting and share issues encountered and best practices found at each site to promote interactions among quality assurance managers. In addition, we are working to improve the effectiveness of internal quality audits, automate inspections, and strengthen the training of quality control personnel.

[Domestic]

Isohara Works; Kitaibaraki Precision Co., Ltd.; Kurami Works; JX Nippon Coil Center Co., Ltd. (Kurami Office, Kawasaki Office); Hitachi Works (Copper Foil Dept.); Ichinoseki Foil Manufacturing Co., Ltd.; JX Metal Smelting Co., Ltd. (Saganoseki Smelter & Refinery, Hitachi Works); Japan Copper Casting Co., Ltd. (Saganoseki Works); JX Metals Trading Co., Ltd. (Takatsuki Plant); JX Metals Precision Technology Co., Ltd. (Esashi Works, Nasu Works, Kakegawa Works); TANIOBIS Japan Co., Ltd. (Headquarters, Mito Plant); and Toho Titanium Co., Ltd. (Headquarters/Chigasaki Plant, Hitachi Plant, Yahata Plant, Wakamatsu Plant, Kurobe Plant)

[Overseas]

Nippon Mining & Metals (Suzhou) Co., Ltd.; Nikko Fuji Precision (Wuxi) Co., Ltd.; JX Nippon Mining & Metals Dongguan Co., Ltd.; Nikko Metals Taiwan Co., Ltd. (Longtan Works, Kuanyin Works); JX Nippon Mining & Metals Philippines, Inc.; JX Nippon Mining & Metals USA, Inc.; JX Nippon Mining & Metals Korea Co., Ltd.; TANIOBIS GmbH (Goslar); TANIOBIS Smelting GmbH & Co. KG (Laufenburg); TANIOBIS Co., Ltd. (Map Ta Phut); Materials Service Complex Malaysia Sdn. Bhd.; Materials Service Complex Coil Center (Thailand) Co., Ltd.; and SCM Minera Lumina Copper Chile

The Quality Control Department is in charge of planning, proposal, promotion, and oversight for enhancement of Group-wide quality control. This department is also engaged in clarifying Group-wide QMS requirements, improving the effectiveness of internal quality audits, and supporting quality improvement activities and quality control education at manufacturing sites.

In fiscal 2021, we continued to remotely conduct internal quality audits at 13 sites in Japan and overseas, despite restrictions imposed by the COVID-19 pandemic.

In fiscal 2021, there were no claims pursued under the Product Liability Act due to personal or property damage caused by defects in products made by Group companies.

In accordance with the Basic Quality Policy, the Group provides customers with information on its products and services through product specifications and Safety Data Sheets (SDS)*. For example, sulfuric acid sold by Group companies is designated as a deleterious substance under Japan’s Poisonous and Deleterious Substances Control Act. By limiting our business partners to sellers of poisonous or deleterious substances and issuing SDSs, we strive to prevent serious negative effects on the occupational health and safety for our customers and their employees after delivery.

Cooperation with suppliers is essential for thorough quality assurance. The Group respond to its suppliers based on quality management standards and quality requirements. Our efforts include conducting regular evaluations and quality audits, reducing quality risks, and improving the quality level of our suppliers. We also conduct Supplier Surveys to promote mutual understanding with our suppliers.

The Group ensures that all employees are thoroughly familiar with the Basic Quality Policy through quality control education. In addition, to we also provide quality control education to all employees to improve their problem identification and resolution capability, helping them to logically infer the root cause of a problem and independently resolve it and improve the quality of their work. These training programs, which range from introductory to advanced courses according to the level of the participants, have become an established part of employee training.

Starting in fiscal 2020, the Company’s Quality Control Department encourages internal quality auditors to acquire qualifications such as QMS Auditor and is introducing retrospective training from outside instructors in order to im-prove their competence.

Quality control education (Headquarters)