The JX Nippon Mining & Metals Vision for Sustainable Copper

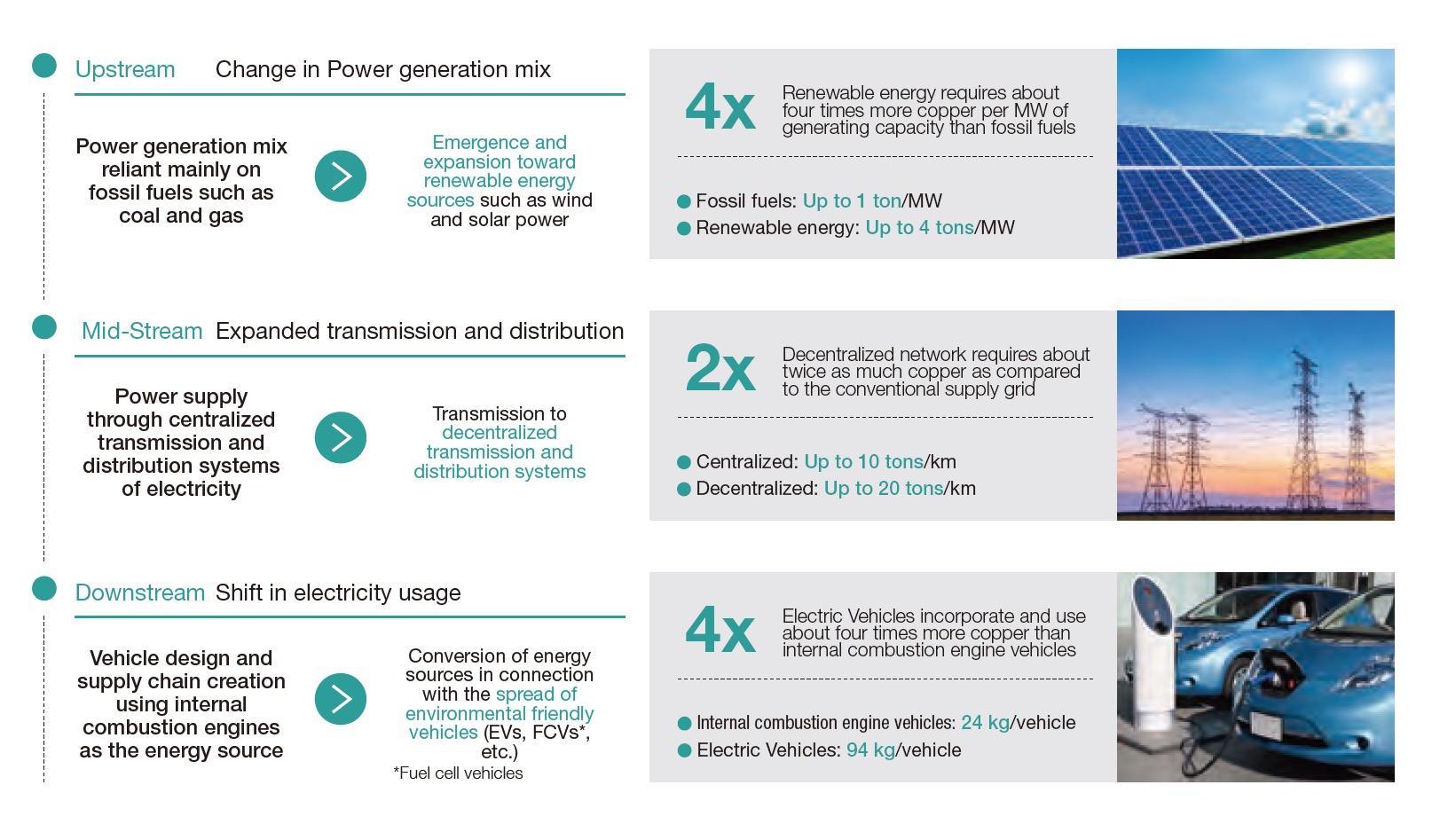

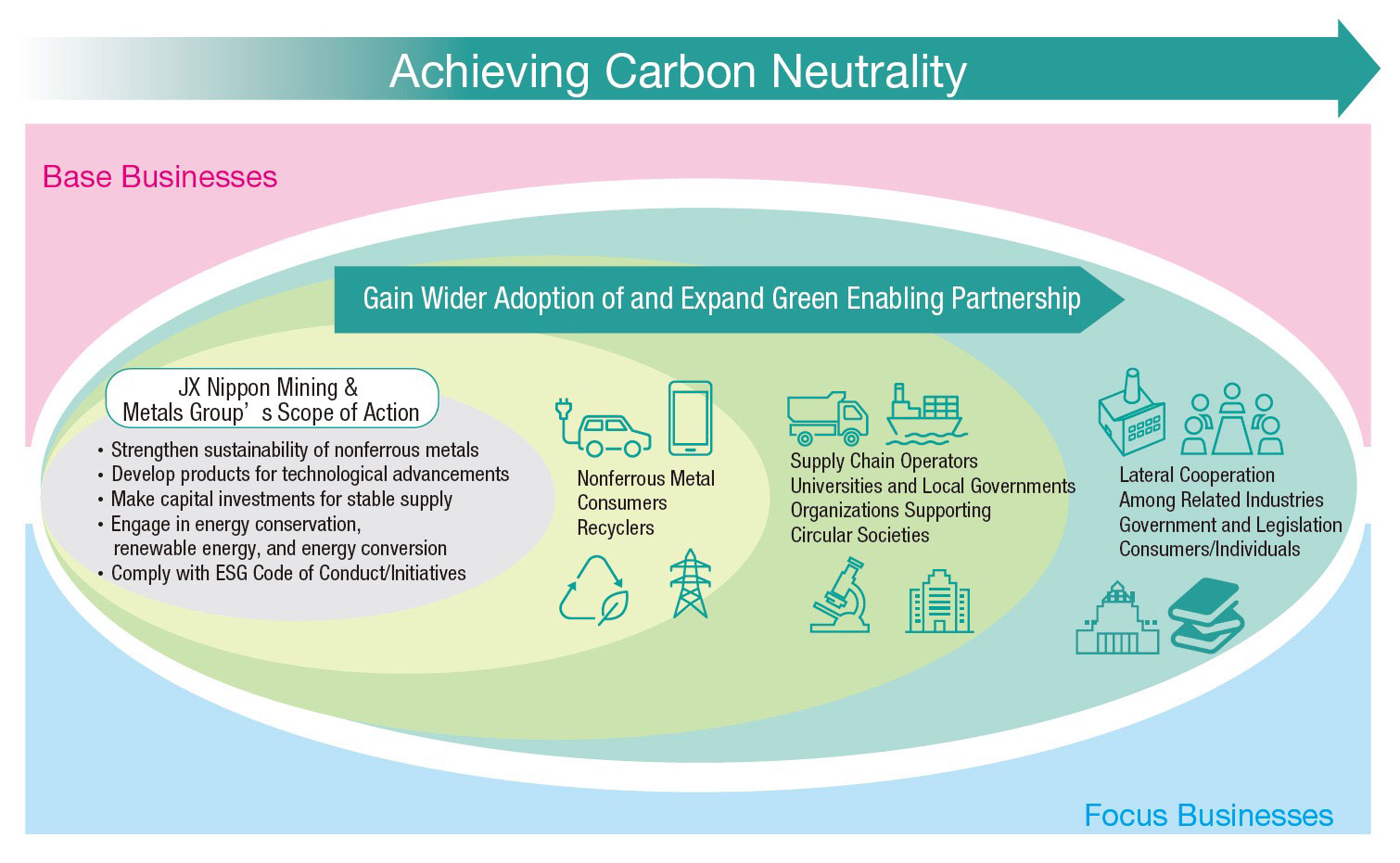

Copper is an essential material for achieving carbon neutrality, thereby copper suppliers and users are regarded as Green Enablers.

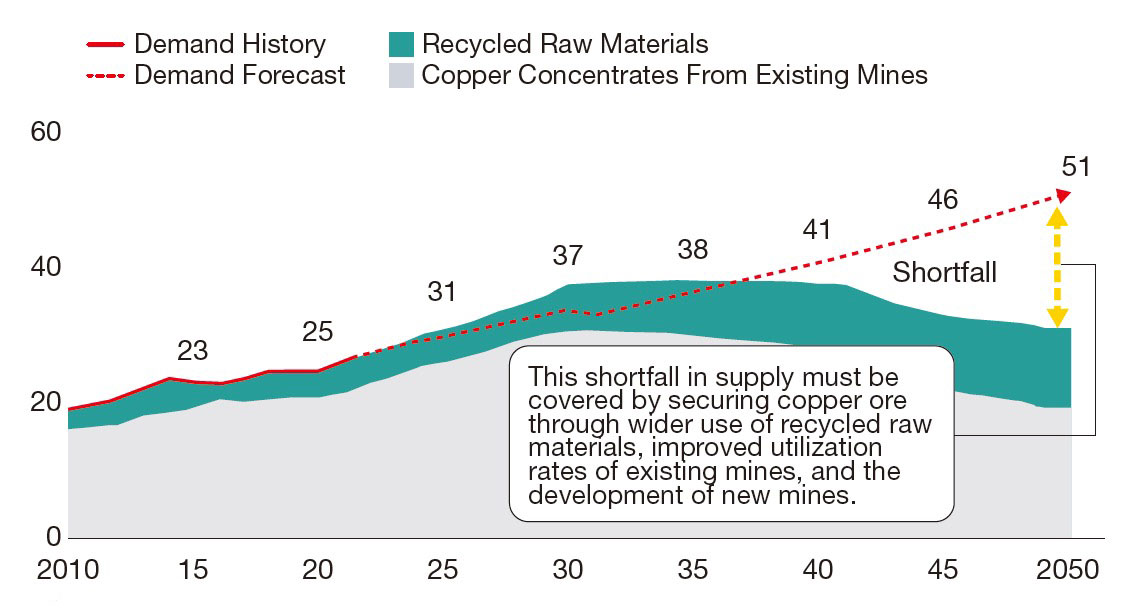

Meeting increasing demand for copper requires an increased supply of copper ore and recycled raw materials

While demand for copper will continue to grow over the long term, the supply of copper ore and recycled raw materials from existing mines is limited, and the supply-demand balance for copper is likely to be very unstable. This delicate balance is why copper ore and recycled raw materials will be essential in meeting the demand for copper, without which the world cannot achieve decarbonization.

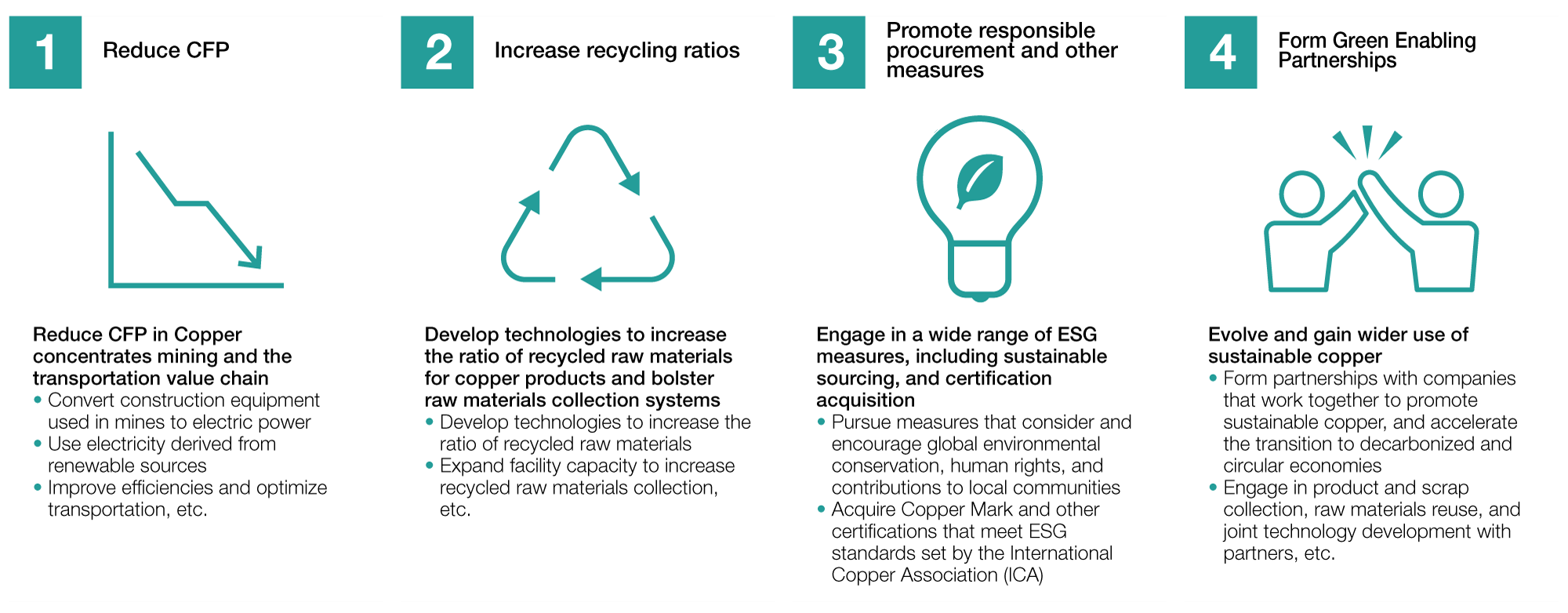

We will pursue four measures to evolve and gain wider use of Sustainable Coppers.

We are striving to reduce Scope 1 CO₂ emissions (fuels and industrial processes) through energy conservation, fuel conversion, and carbon capture and recycling. In connection with Scope 2 emissions (electricity), we completed the switch to CO₂-free electricity or renewable electricity sources at the Caserones Copper Mine, the Saganoseki Smelter & Refinery and Hitachi Works operated by JX Metals Smelting Co., Ltd., and other major sites in Japan and overseas. We reduced CO₂ emissions significantly as a result of these efforts. We are also considering the generation of our own renewable energy sources.

Special Feature 2: The JX Nippon Mining & Metals Group Climate Change Strategy

The Caserones Copper Mine has reduced CO₂ emissions significantly by switching to electricity derived from renewable sources

The JX Nippon Mining & Metals Group strives actively to reduce Scope 3 CO₂ emitted from other companies within our supply chain. For example, the Group is considering a conversion to EVs and FCVs, latest technologies for transportation (see below), and the introduction of alternative fuels in connection with our logistics activities. Mines other than the Caserones Copper Mine in which we have an equity stake are pursuing CO₂-free electricity and the electrification of heavy machinery.

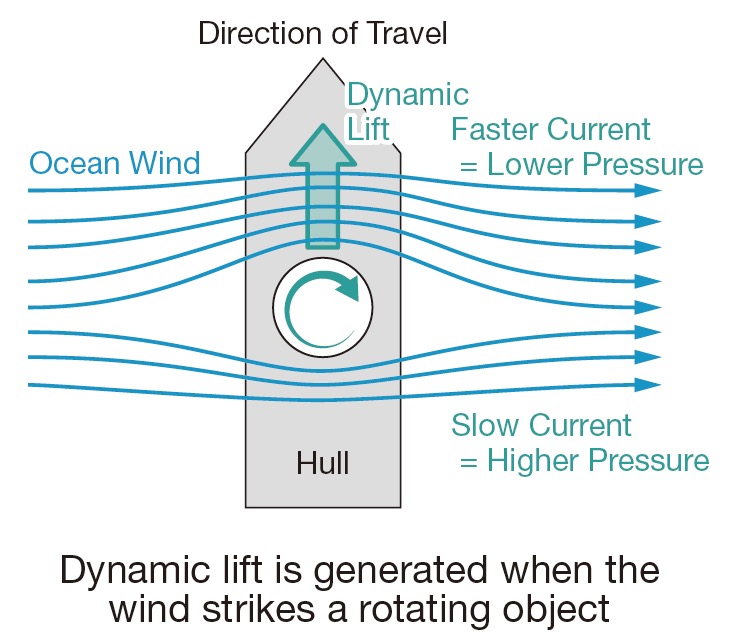

In collaboration with BHP, a major mineral resources company, we are looking into installing rotor sails on the KORYU, the JX Nippon Mining & Metals Group copper concentrates and sulfuric acid cargo ship. Rotor sails are a type of ship propulsion mechanism that uses the Magnus effect to convert pressure differences generated by the rotating cylinders on the hull into dynamic lift. We expect this mechanism to reduce CO₂ emissions by 5% as a result of fuel savings. Final safety verifications are underway, and we expect to install and begin operations in summer 2023 at the earliest.

KORYU After the Installation of Rotor Sails

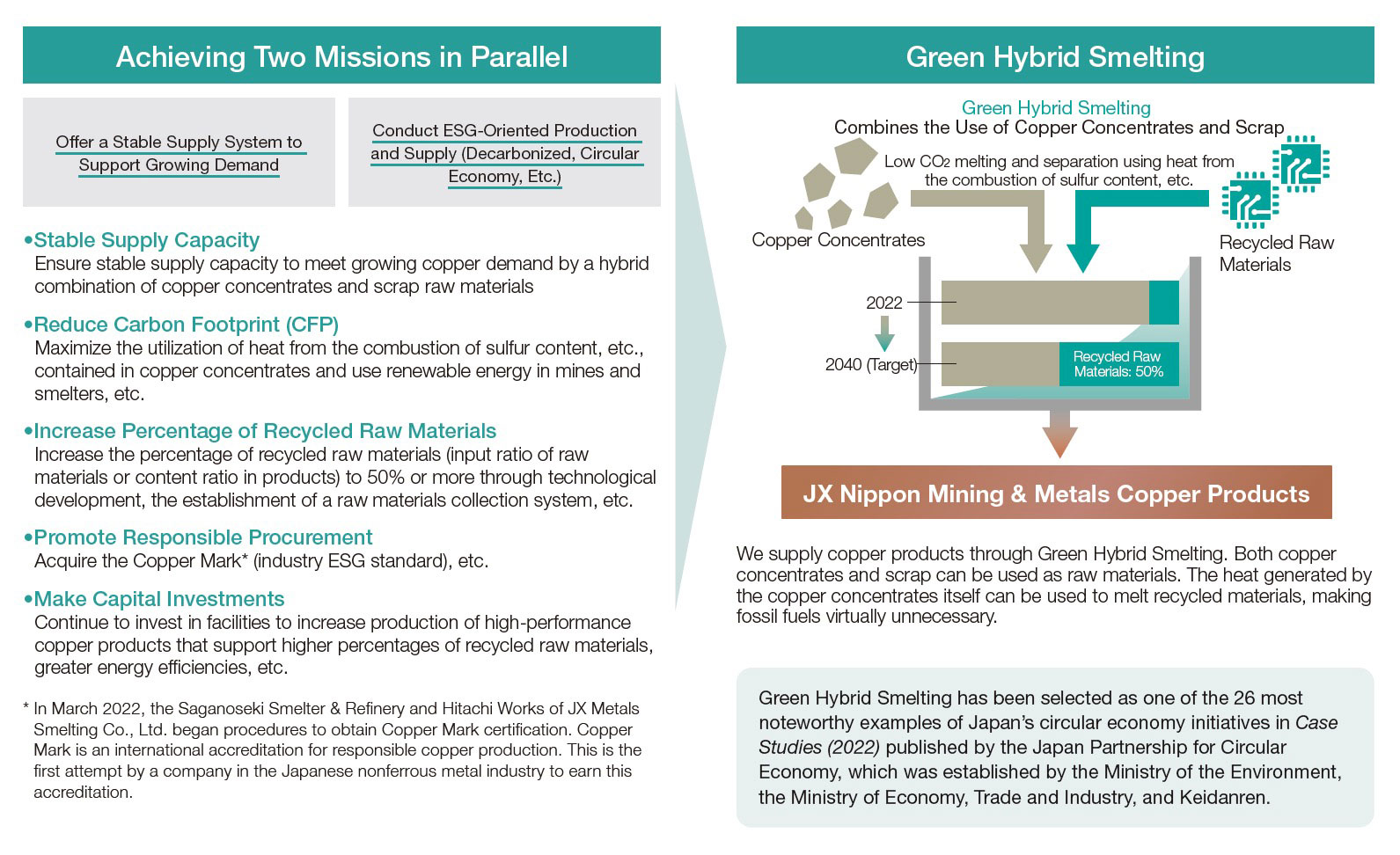

Image of Magnus Effect

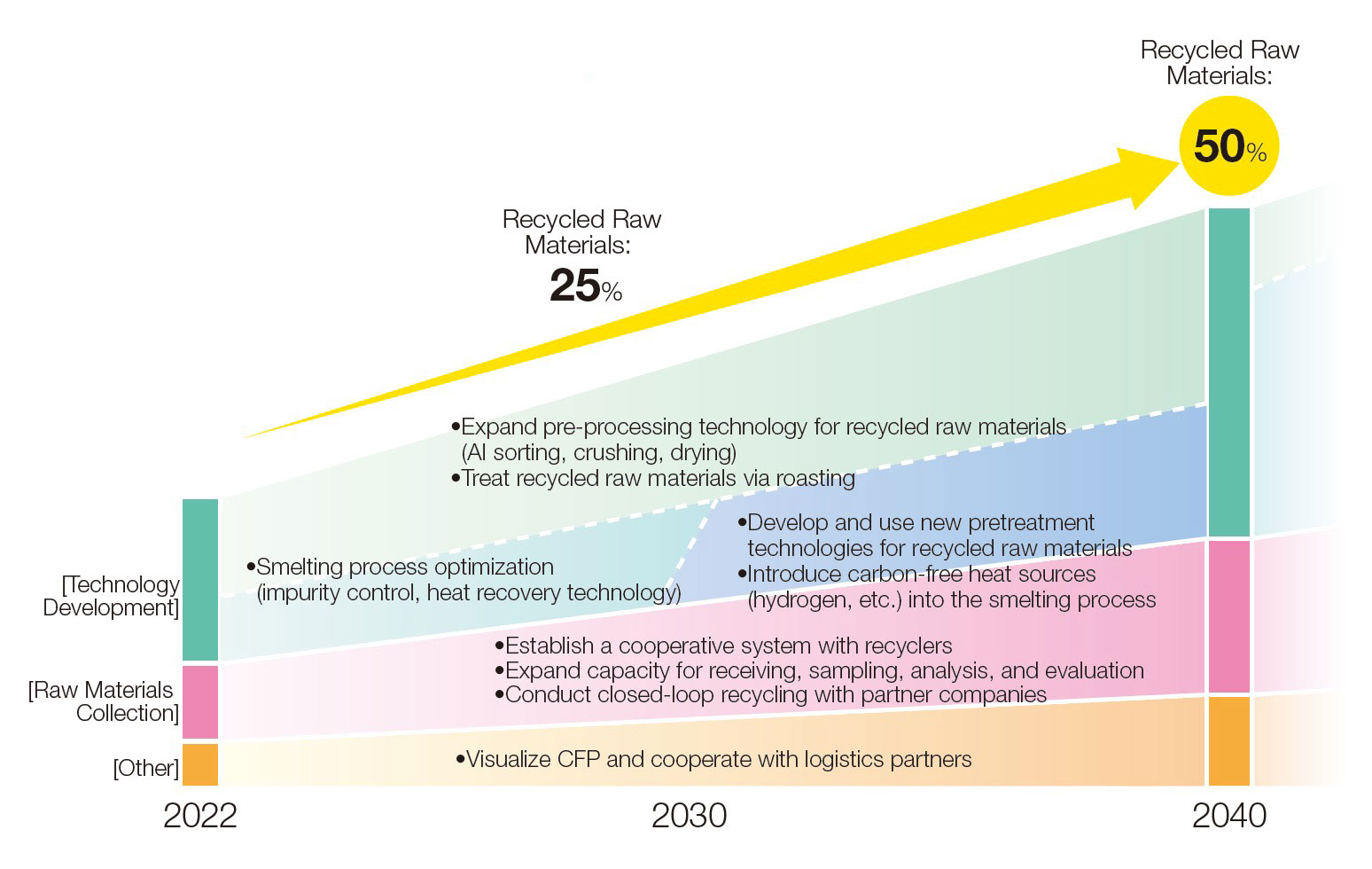

Our flash smelting furnace process not only uses the reaction heat of the raw copper concentrates efficiently to dissolve raw materials, but also uses the excess reaction heat to melt the recycled raw material, eliminating the need for fossil fuels or other resources. We pursue the optimal combination of copper ore and recycled materials through our Green Hybrid Smelting to achieve sustainable production of copper. Here, we aim to evolve Green Hybrid Smelting that uses 50% or more recycled raw materials (input ratio of raw materials or content ratio in products) by 2040. The table on the right shows specific issues and measures.

The Saganoseki Smelter & Refinery and Hitachi Works operated by JX Metals Smelting Co., Ltd. are working toward Copper Mark certification under an audit of 32 ESG criteria (see list at right) as defined by the International Copper Association (ICA).

The Group is also bolstering ESG initiatives by conducting activities in accordance with the RBA Code of Conduct. Of the sites that underwent VAP audits to assess compliance with the RBA Code of Conduct, the Isohara Works and the Chigasaki Plant of Toho Titanium Co., Ltd. received a perfect score of 200 points, being awarded Platinum status, the highest status under the RBA certification program.

Saganoseki Smelter & Refinery, JX Metals Smelting Co., Ltd.

Hitachi Works, JX Metals Smelting Co., Ltd.

We form Green Enabling Partnerships with companies who work together to promote sustainable copper. Through these partnerships, we accelerate the transition to decarbonized, circular economies as well as engage in product and scrap collection, the raw materials reuse, and joint technology development.

Green Enabling Partnership Logo

Carbon Footprint (CFP): The amount of greenhouse gas emissions throughout the entire life cycle of a product or service, from procurement of raw materials to disposal and recycling, converted to CO₂

Scope 1: Direct greenhouse gas emissions from in-house fuel use and industrial processes

Scope 2: Indirect greenhouse gas emissions from the use of electricity, heat, and steam supplied by other companies.

Scope 3: Greenhouse gas emissions of other companies related to business activities (e.g., use and disposal of products) other than Scope 1 and Scope 2

Responsible Business Alliance (RBA): An industry association consisting mainly of electronics manufacturers and their suppliers, including many of our customers in the advanced materials field. The RBA works to improve social, environmental, and ethical aspects of the global supply chain