(Photo) Oshima cherry blossoms at the Hitachi Mine, where greenery was restored to a mountain devastated by smoke pollution

The Group maintains a keen awareness of the impact our business activities have on the environment, and our basic policy is to contribute to conservation of the environmental on a global scale by promoting the development of technologies that enhance the productivity of resources and materials. In addition, we have established in our Basic Environmental Policy that we will take action toward the formation of a decarbonized and recycling-oriented society, and we are working to reduce our environmental impact with clear goal management. As we execute business, we seek to reduce our environmental impact at every stage of the supply chain.

Assessment: Achieved/Steady Progress Not Achieved

| KPI | Fiscal 2020 Results/Progress | Assessment |

|---|---|---|

| Total In-house CO₂ Emissions: Promoting initiatives to achieve net zero CO₂ emissions in fiscal 2050 and 50% reduction in fiscal 2040 (vs. fiscal 2018) |

To achieve these targets, we launched the Carbon Free Project (CFP) across the entire Group, implementing and starting a variety of initiatives, including the introduction of CO₂-free electricity at each of our sites. In addition, based on these activities, we have set a new target of 50% CO₂ emissions reduction in fiscal 2030, ten years ahead of schedule in our current interim target set in fiscal 2021. Special Feature 1 |

|

| Increase Percentage of Recycled Raw Materials: Expand the Breadth of Recycled Materials to be Treated | In addition to setting a target to substantially increase the ratio of recycled materials used in copper smelting to 50% of total, we have worked to improve our internal technology development system to achieve this target, and we have expanded our collection centers and built new distribution sites for greater treatment of recycled materials. Special Feature 2 |

|

| Landfill Disposal Rate: Less than 1% in Fiscal 2020 | In addition to complying with various environmental regulations, we have set a goal of keeping our landfill disposal rate at no more than 1.0% in order to cut down on waste with the aim of minimizing our impact on the environment. Our landfill disposal rate in fiscal 2020 was 0.51%. ESG Data Book (Waste Materials and By-Products) |

Environmental Management

Environmental ManagementAs a comprehensive manufacturer of nonferrous metals and advanced materials, the JX Nippon Mining & Metals Group is rising to the challenge of innovation in the productivity of resources and materials. Committed to compliance with environmental regulations, we carry out the following initiatives in order to proactively strive for environmental conservation on a global scale, including measures against global warming, and contribute to building a sustainable society.

1. We will contribute to achieving a decarbonized society by promoting technological innovation and energy transition and aiming for zero greenhouse gas emissions.

2. We will supply environmentally-friendly advanced materials to support the growth and advancement of society.

3. We will promote resource recycling and aim for zero emissions in all our business activities.

4. We will thoroughly raise each employee’s awareness of environmental conservation through environmental education, leading to business activities with less environmental impact.

5. We will share information on environmental conservation activities with stakeholders and seek to operate in harmony with society.

Through steady operation of environmental management systems, the Group works to ensure compliance with environmental laws and regulations. The Environment & Safety Department at the Head Office monitors and supervises the state of compliance and reports to the ESG Committee through the Safety and Environment Committee. At their annual meeting, environmental management supervisors work to strengthen our compliance system by providing information on legal and regulatory trends and reporting on the status of compliance at each operating site. We additionally reinforce employees’ knowledge of laws and regulations by holding rank-specific education and training regularly at the head office and operating sites.

In fiscal 2020, there were no adverse dispositions from regulatory authorities (including license revocation, orders to cease operations, orders to cease use of facilities, orders for improvement, fines, etc.) for violations of environmental laws and regulations.

Individual operating sites implement internal environmental audits at least once a year. In addition, they periodically undergo environmental and safety audits by the Environment & Safety Departments of the Head Office and of JX Metals Smelting Co., Ltd. Audits were conducted at 17 sites in fiscal 2020.

Activities in the areas of health and safety and environmental conservation are planned, promoted, and reviewed by the Safety and Environment Committee, an organization under the ESG Committee. The Safety and Environment Committee meets once every six months.

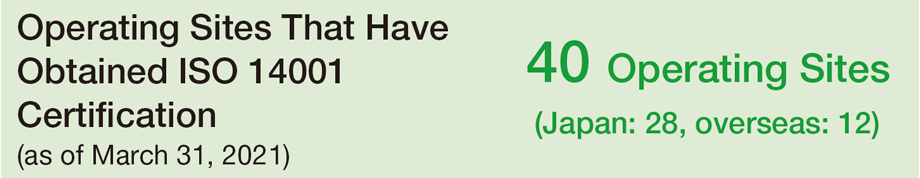

The JX Nippon Mining & Metals Group has established environmental management systems in line with ISO 14001 standards for ensuring achievement of the Action Plan for Environmental Protection, which was drawn up to reflect the Basic Environmental Policy. A multilevel organizational structure has been created, including various committees and subcommittees, in which everyone, from senior management headed by the president to employees at operating sites and affiliated companies, works together to promote environmental conservation and mitigate environmental risk. No environmental accidents occurred in the Group in fiscal 2020.

The Group has set a Green Purchasing Policy, aimed at reducing environmental and other social impacts when procuring materials and equipment. Based on this policy, we have drawn up Green Purchasing Guidelines setting out specific requirements for choosing suppliers. This Guideline contains “mandatory conditions (minimum requirements)” for mandatory compliance, and “preferred conditions (preferences)” that we ask our business partners to consider. These conditions are applied to all of our suppliers. Supplier compliance with these guidelines is checked in our CSR Procurement Questionnaire survey.

Initiatives for Environmental Conservation

Initiatives for Environmental ConservationThe JX Nippon Mining & Metals Group is strengthening its efforts toward decarbonization, like halving its own total CO₂ emissions by fiscal 2030 and achieving net zero CO₂ emissions by fiscal 2050. In addition, we are expanding recycling and other businesses contributing to a resource recycling-oriented society. Beyond that, we are continuously taking actions to preserve the environment, including nature conservation.

Initiatives for Decarbonization (Special Feature 1) Initiatives for Resource Recycling (Special Feature 2)In the Group's business activities, we use large quantities of water in our copper mining operations, as well as for cooling water (mainly seawater) used in smelters. We recognize that water resources are not only essential for our Group's business activities, but also important resources for the local communities where our production sites are located. With this in mind, we are doing our best to make sure that these sites make effective use of water resources by properly monitoring water consumption and exploring methods for reduced use or reuse.

At the Caserones Copper Mine, a mine where we have operations, we have set limits on water use that are stricter than those set by the local authorities, and we monitor the balance of water intake and discharge. In areas downstream from the mine, we also desalinate seawater, providing water supplies used by local residents for agriculture and general home use.

In the Group’s business activities, we recognize that we need to provide due care in regard to biodiversity, especially in our mining operations, an area strongly linked to biodiversity. Here, we are carrying out a variety of initiatives both in Japan and overseas.

At the Caserones Copper Mine, 48,200 seedlings from 15 native flora species are being planted in an area spanning 1.43 square kilometers to protect biodiversity. The areas where these are being planted are Ramadilla on the mine site and around the off-site areas of Maitencillo and Amolanas. In addition to reforestation, we are monitoring the development of plants native to the area and conducting research on the impact of climate and other factors on the propagation and distribution of plants native to the high altitudes around the Caserones Copper Mine.

In Japan, we are continuously engaged in forest maintenance activities, such as tree planting and clearing, focusing on closed mine sites, to maintain and improve the natural environment and conserve biodiversity.

Plants native to the Caserones Copper Mine area

From its founding in 1905, the JX Nippon Mining & Metals Group has been engaged in mining operations across Japan. By ensuring a steady supply of nonferrous metals and other resources, we contributed to Japan’s economic growth. Today, however, operations have ceased in nearly all mines as their mineral resources have dried up. Still, in closed mines we provide acid mine drainage (AMD) treatment and work to maintain and restore the natural environment.

Under the Mine Safety Act, AMD treatment is an ongoing obligation at 12 of the 39 closed mines managed by the Company. JX Nippon Mining Ecomanagement oversees the process. The work mainly consists of detoxifying the highly acidic mine drainage generated from the mines and tailings dams, which contain heavy metals, and maintaining and preserving the tailings dams and galleries of the mining sites. AMD occurs when rainwater or other water comes into contact with materials such as ores remaining after the mine is closed or the rubble and slag of tailings dams. Therefore, as AMD is generated continuously, treatment facilities have to operate 365 days a year. This is one way we work to protect the natural environment by managing closed mines.

Closed mines where AMD treatment is carried out

The Group believes that it is important to minimize the impact on the environment and society in the surrounding areas when closing a mine. We have formulated a mine closure plan for the Caserones Copper Mine through dialogue with the relevant authorities, local communities, and other stakeholders, and have made financial and other preparations to implement the necessary measures, thereby ensuring appropriate responses in the event of its closure.

The Group has voluntarily established chemical substance management standards. We strive to mitigate the harmfulness of these substances by defining sets of substances that shall be either prohibited from use or eliminated (e.g., many chlorinated organic compounds, mercury compounds, and lead compounds) and sets of substances to be monitored (e.g., phthalate esters and volatile organic compounds such as toluene and xylene), and controlling their use. In addition, the Green Procurement Guidelines clearly identify substances that must not be included in manufacturing processes, materials, or equipment, and we ensure our suppliers are aware of these. Furthermore, we strive to provide safety information to our customers and all other product stakeholders.

The Group contributes to environmental conservation by detoxifying hazardous waste through our treatment businesses for low-concentration PCBs and asbestos. In 2014, JX Nippon Tomakomai Chemical Co., Ltd. became the first firm in Hokkaido to receive certification from the Minister of the Environment as a detoxification facility for treating low-concentration PCB waste. In addition, JX Nippon Environmental Services Co., Ltd. is engaged in the melting and detoxification of asbestos. The company treated approximately 3,254 tons of waste asbestos in fiscal 2020.

We are also proceeding with treatment of Group-owned equipment with high-concentration PCBs at the Japan Environmental Storage & Safety Corporation (JESCO). We have completed treatment at sites outside the Tokyo metropolitan area, and plan to complete treatment at the remaining sites by the disposal deadline. In addition, we are planning disposal of equipment with low-concentration PCBs using private disposal companies such as JX Nippon Tomakomai Chemical Co., Ltd.; this disposal is scheduled to be completed by fiscal 2024, two years before the disposal deadline.

* Polychlorinated biphenyls, or PCBs, were often found in insulating oils for transformers and capacitors, as well as in pressure-sensitive photocopiers, due to their excellent electrical insulating properties, but their toxicity has now led to a ban on their new manufacture and import.

Rotary kiln incinerator at JX Nippon Tomakomai Chemical Co., Ltd.