News Release

FY2024

November 12, 2024

JX Advanced Metals Corporation

Development of Copper Powder with Proprietary Surface Treatment for Metal Additive Manufacturing

-Affords Thermal and Electrical Conductivity Comparable to Pure Copper in Laser Powder Bed Fusion Applications-

Utilizing a proprietary surface treatment technology, JX Advanced Metals Corporation (President: Hayashi Yoichi; "the Company") has developed a copper powder (the "developed product" below) for laser powder bed fusion (L-PBF)1 additive manufacturing (AM) applications.

The metal AM can develop innovative products that are not bound by existing manufacturing methods, and are expected to be adopted in a variety of fields, including rocket engine cooling mechanisms and induction heating coils, because of its effectiveness in reducing size, weight, and delivery time, as well as its performance improvement. However, pure copper powders absorb almost none of the heat energy from the near-infrared lasers that are commonly utilized as heat sources in AM, and they are difficult to heat due to their high thermal conductivity, which allows heat to more readily escape, consequently applications that utilize pure copper powders for high-density fabrication have required metal AM technologies that rely on high-powered lasers. Furthermore, in the case of using copper alloy powders instead of pure copper powders, even though heat treatment after printing products created with copper alloy powders typically exhibit 90% or less of the electrical conductivity afforded by pure copper, even after post heat treatment to improve the conductivity. Moreover, they also lead to higher costs due to the extra capital investments and added processing stages that heat treatment requires.

To address these various concerns, the Company, working in collaboration with Alloyed Ltd.,2 a partnering firm in which it holds an equity stake, has developed a new copper powder for L-PBF AM. Produced using a novel surface treatment process aimed at providing improved manufacturability, the developed product enables high-density fabrication with the 400 W and 500 W near-infrared lasers commonly used in L-PBF AM, and it allows the fabrication of items possessing levels of electrical conductivity comparable (≧99% IASC3) to that of pure copper. Another benefit is that items fabricated using the developed product do not require any post heat treatment. Consequently, compared to items manufactured with copper alloy powders, they can be produced using a more streamlined process, contributing to improved productivity. Moving forward, the Company will soon begin shipping samples of the developed product on an orderly basis and launch promotional sales.

Incidentally, the Company will exhibit the developed product at Formnext, the world's largest trade show in the field of AM, to be held November 19-22 this year in Frankfurt, Germany. Please visit if you have the chance.

Going forward, the Company will continue to contribute to the advancement and evolution of society as a global leader in cutting-edge materials.

Notes

1. An AM method in which a laser or electron beam is irradiated onto a flat layer of material powder to melting and sintering it to the cross-sectional shape of a model, and as each layer is deposited, the molding stage is lowered to deposit the next layer.

2. Alloyed began as a spin-out from a research group at Oxford University in the UK. Its main business is in the design of metallic alloys and platforms for metal AM.

3. Company test results.

Reference Information

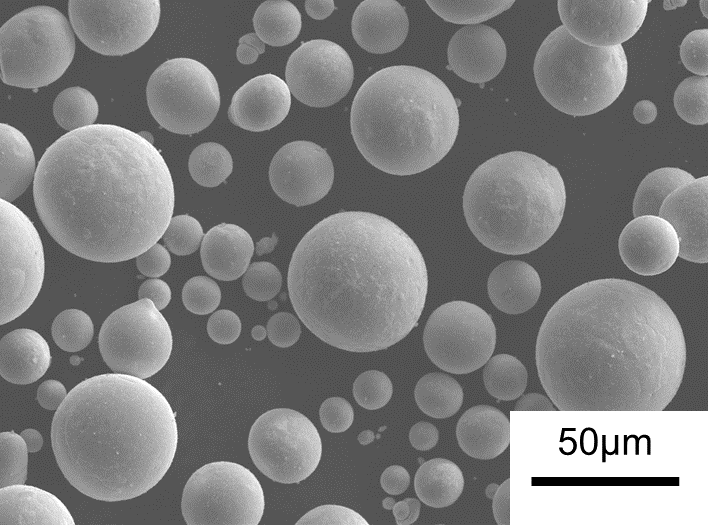

Fig.1 Enlarged photo of the developed product.

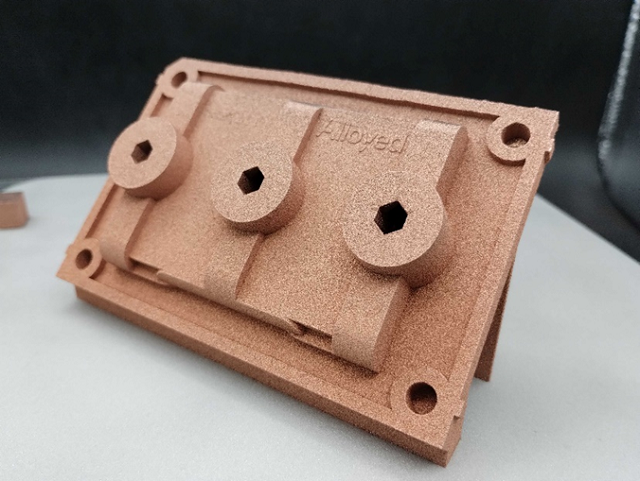

Fig.2 Copper liquid cooling plate fabricated with the developed product (manufactured by Alloyed Ltd.).

Table1 Comparison with other copper powders for AM (with 400 W and 500 W lasers)

| Developed product | Copper alloy powder | Pure copper powder (no surface treatment) |

|

|

High-density manufacturability |

Possible | Possible | Difficult |

| Conductivity | High | Low | High |

| Post heat treatment | Not needed | Required | Not needed |