MoSi2 Heating Element

JX Advanced Metals MoSi2 Heating Elements

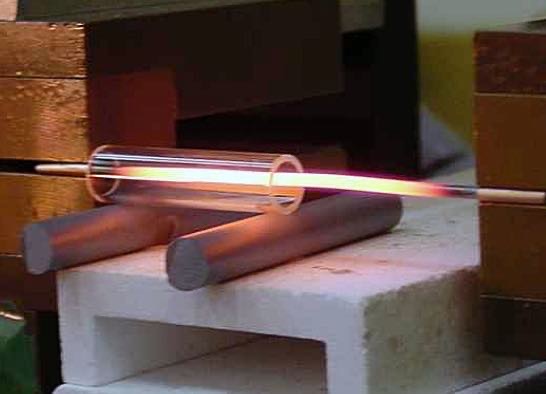

MoSi2 (molybdenum disilicide) heating elements can be used in air (oxygen atmosphere) at temperatures of up to 1800 °C. They are able to generate higher temperatures than other materials also used in air, such as Kanthal® (FeCrAl alloy) wire, Nichrome wire, or SiC (silicon carbide) heating elements. Depending on the furnace design, in some cases they can be used at temperatures even higher than 1800 °C. Their many and varied uses include sintering of ceramics (Al2O3, ZrO2, MgO, etc.), glass melting and heat treatment, power semiconductor wafer annealing, and sintering and tempering of various metals. The high-purity MoSi2 heating elements developed by JX Advanced Metals are available in the following grades. Together with their long life (deformation resistance, base material strength, etc.), we provide MoSi₂ heating elements that solve such issues as workpiece contamination (discoloration), overheating, and pest oxidation.

JX Advanced Metals MoSi2 Heating Elements Lineup

- *1 Indicates the heating element surface temperature, which is highly dependent on the thermal cycling program and other setting conditions.

- *2 Ar, He and N2 gas atmospheres are assumed. It may be necessary to regenerate the oxide film periodically.

→Good

→Superior

| Grade | Heat resistant |

Pest oxidation resistance | Discoloration resistance | Purity | Maximum Element Temperature*1 | Features | |

|---|---|---|---|---|---|---|---|

| Air (℃) |

Inert gas*2 (℃) |

||||||

| Standard (1800 ℃) Grade | 1800 | 1700 | For general industrial furnace use | ||||

| Anti-Discoloration Grade | 1900 | 1800 | Minimizes workpiece contamination/discoloration | ||||

| 1900 ℃ Grade | 1900 | 1800 | Can be used at furnace temperatures above 1800 ℃ Note: Depend on furnace design |

||||

| Anti-Pest Oxidation (AP) Grade | 1800 | 1700 | Minimizes pest oxidation at low temperature | ||||

| Super Clean (SC) Grade | 1800 | 1700 | Minimizes contamination by alkaline metals & heavy metals | ||||

Standard (1800 ℃) Grade

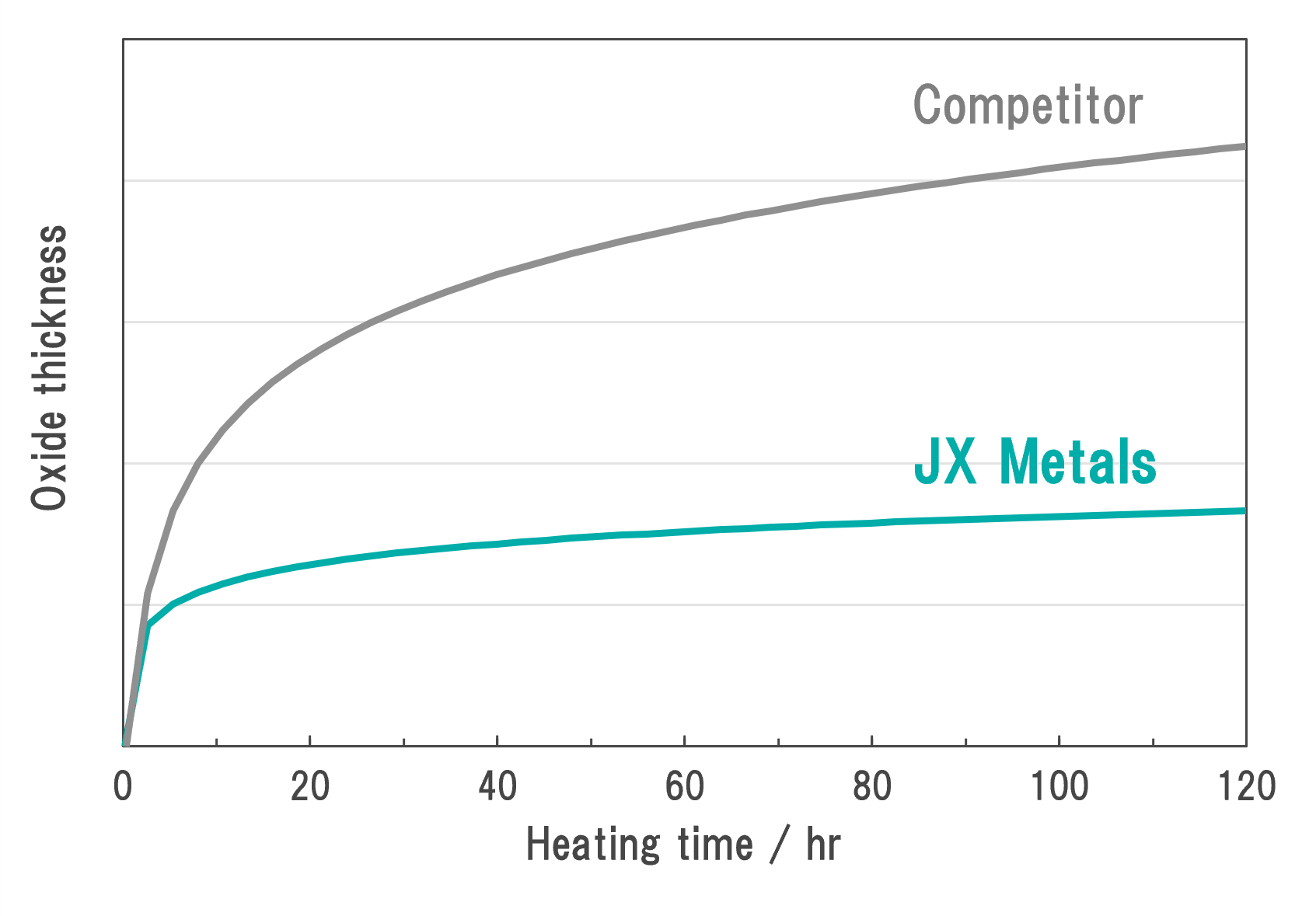

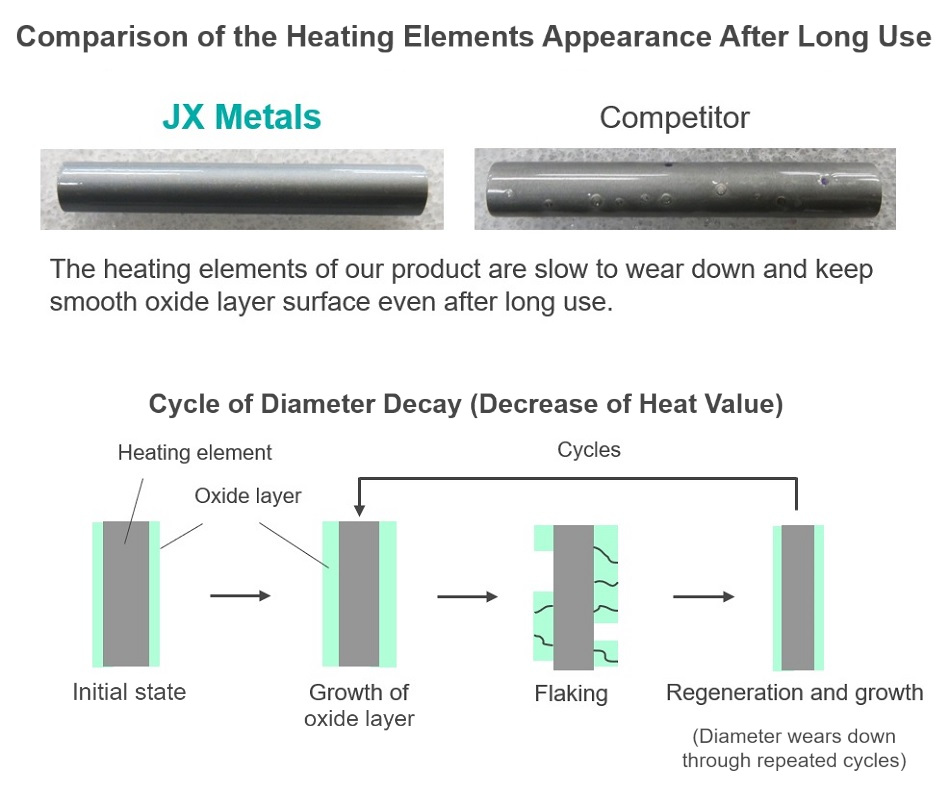

JX Advanced Metals has succeeded in extending the lifetime MoSi2 heating elements by achieving higher purity of the surface oxide layer (oxidation protection layer).The high-purity oxide layer greatly reduces the oxygen diffusion rate, for longer lifetime in a high-temperature oxidizing atmosphere.

Comparison of Oxide Layer Growth Rates on the Surface of Heating Elements

Anti-Discoloration Grade

We have developed a MoSi2 heating element that reduces discoloration during ceramics sintering. It is effective in reducing the discoloration that can occur when firing heat-resistant crucibles, for example. It is further applicable to rapid temperature rises.

Appearance of Ceramics After Heat Treatment

| Heated sample | Anti-Discoloration Grade | Standard Grade | Competitor |

|---|---|---|---|

| Ceramics A |

|

|

|

| Ceramics B |

|

|

|

The high effectiveness of the Anti-Discoloration Grade heating element in reducing discoloration compared to other grades and competing products has been demonstrated with various kinds of ceramics.

1900 ℃ Grade

We have developed a MoSi2 heating element that can be use at even higher temperatures than Standard Grade.

Available for furnace temperatures higher than 1800 ℃ even in air,

1900 ℃ Grade can cover wider range of temperature condition than conventional products.

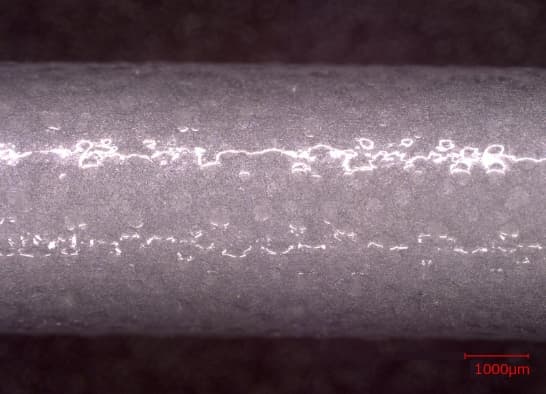

Heating Elment Appearance After Heating to 1800℃

A robust oxide layer is formed on the surface of 1900 ℃ Grade, providing excellent durability in high-temperature use.

Trace of degassing was observed on surface of oxidation layer in Standard Grade.

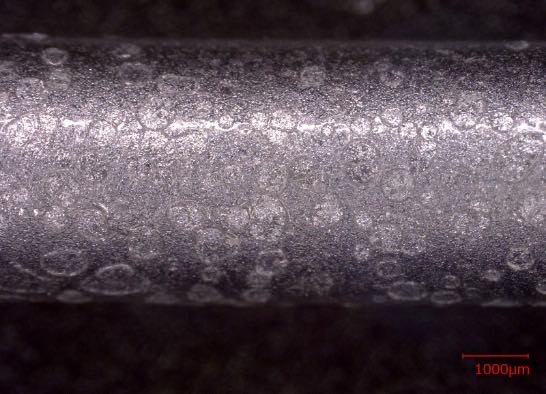

Anti-Pest Oxidation (AP) Grade

We have developed a MoSi2 heating elements that is suppressing “pest oxidation” in low-temperature use. It enabled to use for a long use at low temperatures, which was considered as very difficult conventionally.

This grade would be also applicable for terminal part alone for jointing to other kinds of grades.

What is a Pest Oxidation?

JX Advanced Metals AP Grade suppresses pest oxidation effectively.

In above 1000℃, Si would be oxidized selectively on MoSi2 (Ⅰ) and an excellent anti-oxidation layer would be formed. On the other hand, at 600 ℃ and below, Mo and Si would be oxidized simultaneously (Ⅱ) and cause to pulverization phenomenon “Pest”. Furthermore, if MoO3 is formed in defects site, pulverization accelerated due to volume expansion and high vapor pressure of itself.

5MoSi2 + 7O2 → Mo5Si3 + 7SiO2…(Ⅰ)

2MoSi2 + 7O2 → 2MoO3 + 4SiO2…(Ⅱ)

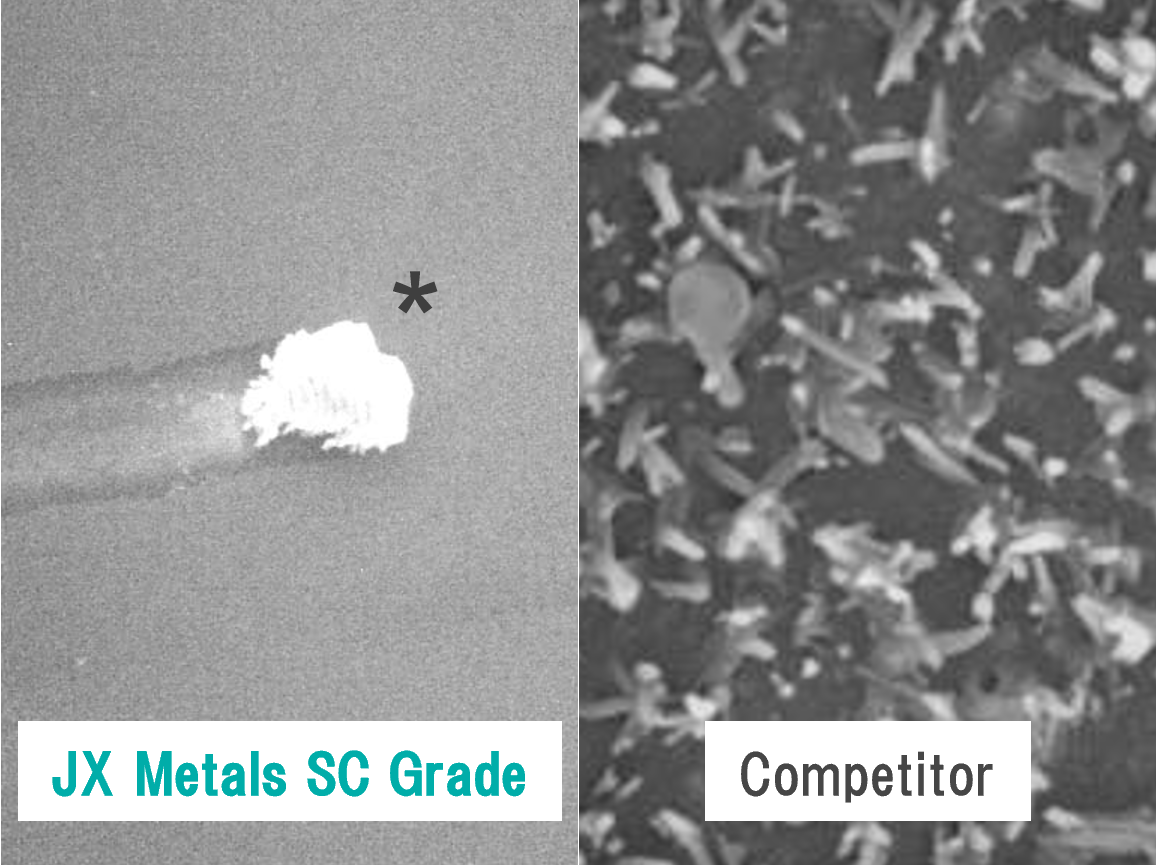

Super Clean (SC) Grade

We have developed a MoSi2 heater that does not release alkali metals and heavy metals, which are sources of contamination, from the heater surface during the high-temperature heat treatment process. It provide a clean heat treatment circumstance such as semiconductor wafers.

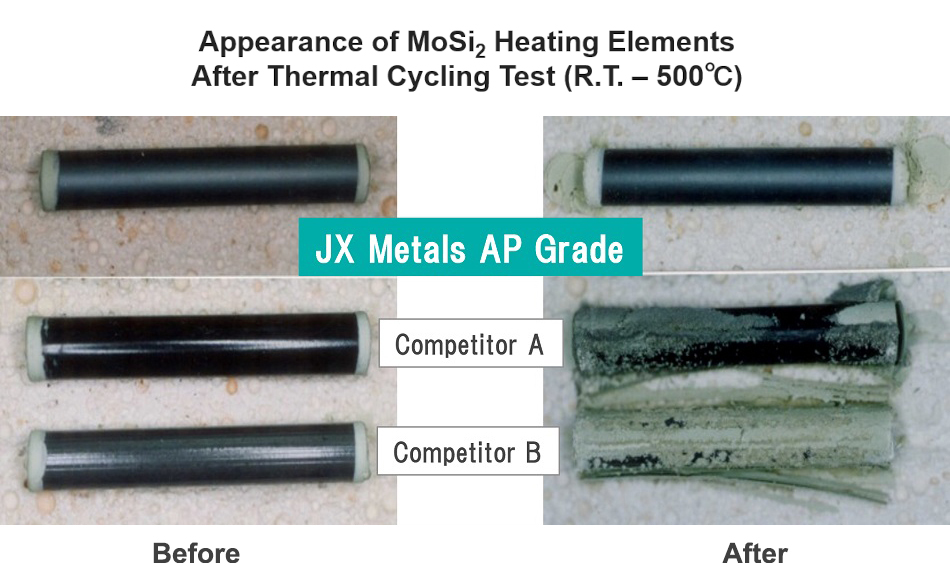

Comparison of Impurity Levels in MoSi2 Heating Element Products

SC Grade is confirmed to contain much less impurities than that of competitor.

- Note: Only for reference (NOT guaranteed).

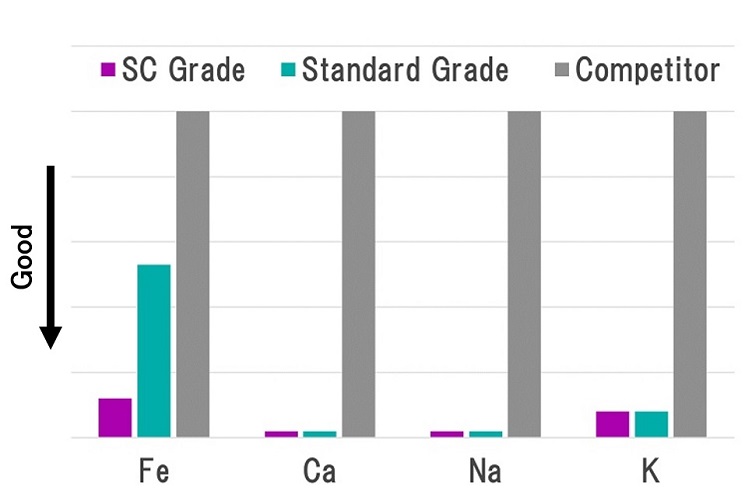

Impurity Capturing Test

The volume of impurities collected in the test is lower for SC Grade than competitor.

- The deposited Au was deliberately stripped off and accumulated. It is apparent that the surface of inner wall is smooth with no impurities on it.

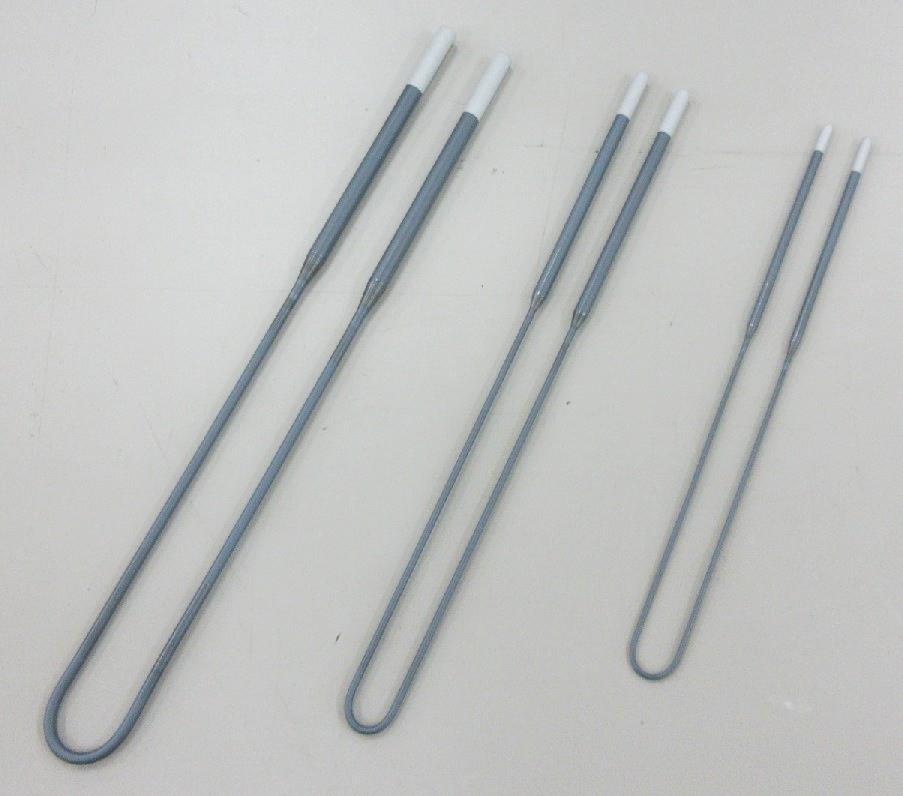

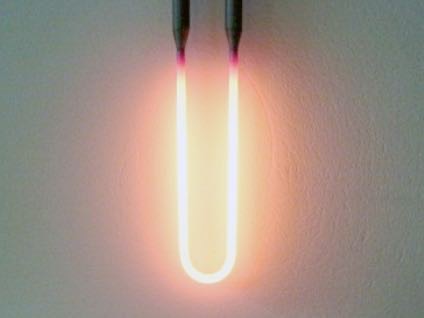

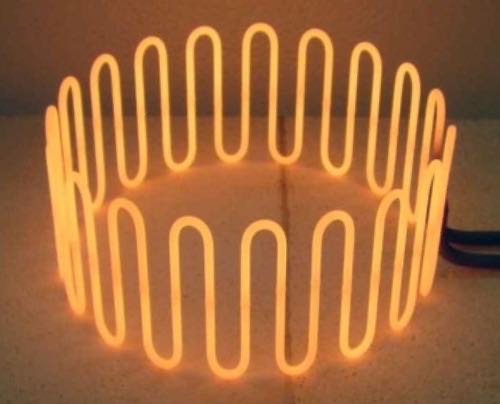

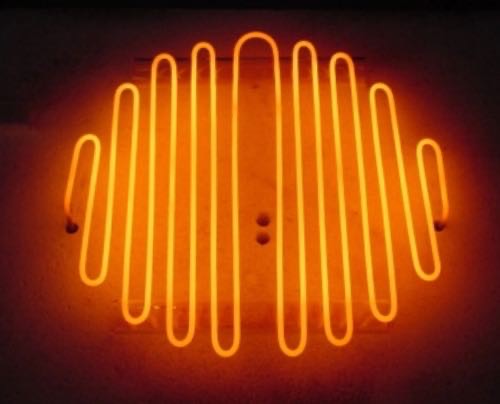

Specially Shaped Heating Elements

As customer needs are diversifying, heating elements need to be made in various shapes.

JX Advanced Metals can propose heating element shapes for various applications; moreover, we can process them into special shapes that minimize the number of terminals which cause heat loss.

The excellent technique makes it possible to provide MoSi2 heating elements with uniform heating as well as energy efficiency.

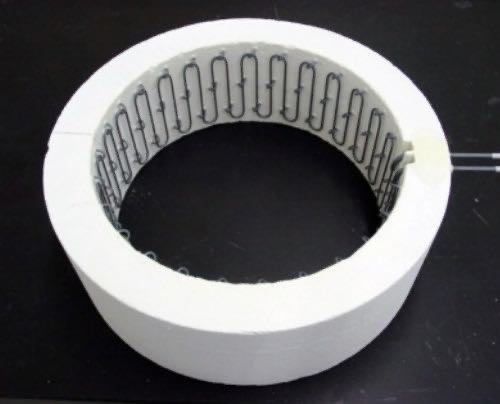

Panorama shape

(For quick heating)

Substrate shape

(For substrate heating)

Irregular panoramic heater

(For partial heating)

Panoramic modular heater

(With excellent heating uniformity

in a cylindrical area)

All grades element are available in special shapes.

Appendix

Available Variations for Each Products

Products Range

| Grade | Combinations of heating elements / terminal (diameters, mm) | ||

|---|---|---|---|

| Φ3/6 | Φ4/9 | Φ6/12 | |

| Standard (1800 ℃) Grade | |||

| Anti-Discoloration Grade | |||

| 1900℃ Grade | |||

| Anti-Pest Oxidation(AP) Grade | |||

| Super Clean(SC) Grade | |||

→Available

→Please contact us for availability.

Combinations of elements of different grades are also available.

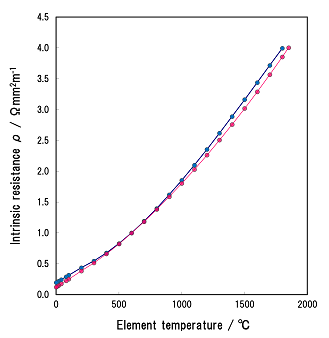

Correlation Between Element Temperature and Electrical Resistivity

Electrical resistivity of our heating elements is standardized for all grades. Since, our products show a similar tendency to competitors’ elements and can be installed in the furnaces currently in use.

Inquiries accepted 24 hours a day