Corson Alloys

Compare Features and Typical Applications

Corson Alloys

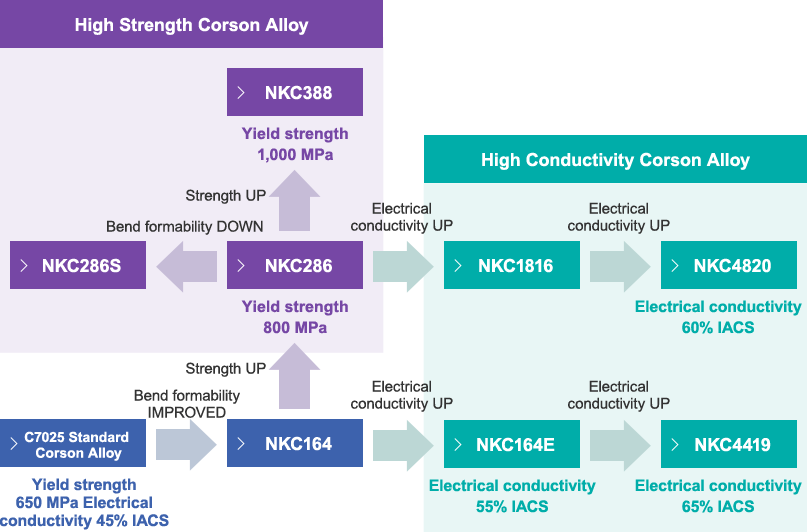

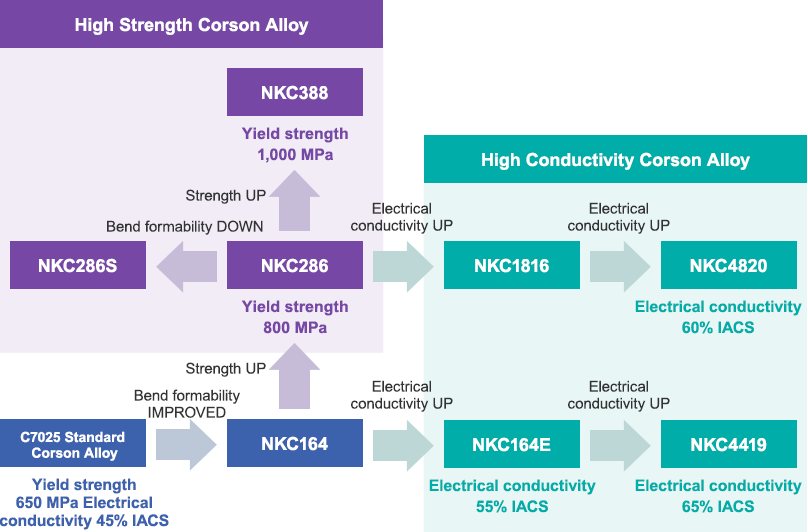

For decades we have conducted R&D aimed at developing new Corson alloys and improving existing ones. The result is a wide network of patents covering Corson alloys with superior strength, conductivity, and bend formability, for which we have achieved the top share in the industry.

A Corson alloy is a special type of copper alloy made using nitrogen and silicon as the principal alloying elements. Taking advantage of the combination of high strength, conductivity, and bend formability, these alloys are used mainly for connector contacts and lead frames in personal computers, mobile phones, and other electronic devices. Today this alloy has become an indispensable metal material in our data-driven society.

| Alloy name | Composition | Features | Applications |

|---|---|---|---|

| Cu-3.0Ni-0.65Si-0.15Mg | Representative Corson alloy | Connectors, lead frames, CPU sockets | |

| Cu-1.6Ni-0.4Si-0.5Sn-0.4Zn | Corson alloy with excellent balance of strength and electrical conductivity | Wiring harnesses, connectors | |

| Cu-2.8Ni-0.6Si-0.5Sn-0.4Zn | Corson alloy with strength exceeding that of C7025 | Connectors, wiring harnesses | |

| Cu-2.8Ni-0.6Si-0.5Sn-0.4Zn | Lower Young's modulus than NKC286 | Connectors, wiring harnesses | |

| Cu-3.8Ni-0.8Si-0.1Mg-0.13Mn | Highest level of strength among Corson alloys | Connectors, switches | |

| Cu-1.6Ni-0.35Si | High-conductivity Corson alloy with spring properties | Connectors, battery terminals | |

| Cu-1.9Co-0.44Si | High-conductivity Corson alloy with spring properties | Connectors, battery terminals | |

| Cu-1.5Co-0.5Ni-0.48Si | High-strength, high-conductivity Corson alloy with spring properties | Connectors, battery terminals | |

| Cu-1.8Ni-1.0Co-0.6Si-0.15Cr | Corson alloy with good balance of strength and electrical conductivity | Connectors, CPU sockets |

Compare Composition and Properties

Corson alloy composition and properties

Chemical Composition (wt%)

| Copper Alloy Name | C7025 | NKC164 | NKC286 | NKC286S | NKC388 | NKC164E | NKC4419 | NKC4820 | NKC1816 |

|---|---|---|---|---|---|---|---|---|---|

| Chemical Composition (wt%) | Cu : Rest Ni : 3.0 Si : 0.65 Mg : 0.15 |

Cu : Rest Ni : 1.6 Si : 0.4 Sn : 0.5 Zn : 0.4 |

Cu : Rest Ni : 2.8 Si : 0.6 Sn : 0.5 Zn : 0.4 |

Cu : Rest Ni : 2.8 Si : 0.6 Sn : 0.5 Zn : 0.4 |

Cu : Rest Ni : 3.4~4.2 Si : 0.70~1.0 Mg : 0.05~0.3 Mn : 0.11~0.20 |

Cu : Rest Ni : 1.6 Si : 0.35 |

Cu : Rest Co : 1.9 Si : 0.44 |

Cu : Rest Co : 1.5 Ni : 0.5 Si : 0.48 |

Cu : Rest Ni : 1.0~2.0 Co : 1.0~2.0 Si : 0.5~1.0 Cr : 0.09~0.2 |

Physical Properties

| Copper Alloy Name | C7025 | NKC164 | NKC286 | NKC286S | NKC388 | NKC164E | NKC4419 | NKC4820 | NKC1816 |

|---|---|---|---|---|---|---|---|---|---|

| Specific Gravity g/cm3 | 8.82 | 8.87 | 8.87 | 8.87 | 8.82 | 8.89 | 8.85 | 8.86 | 8.72 |

| Modulus of Elasticity GPa | 131 | 127 | 127 | 110 | 123 XSH: 135 (TD*) USH: 120 USH: 140 (TD*) |

120 | 127 | 120 | 125 |

| Electrical Conductivity %IACS (@20℃) | 45 TM04S:50 |

43 | 41 | 41 | SH: 38 ESH, XSH, USH: 34 |

55 | 65 | 60 | 47 SH:50 |

| Specific Resistance nΩ·m(@20℃) | 38 | 41 | 42 | 42 | SH: 45.4 ESH, XSH, USH: 50.7 |

30 | 27 | 29 | 37 |

| Thermal Conductivity W/(m·K) | 180 | 170 | 165 | 165 | SH: 160 ESH, XSH, USH: 143 |

240 | 260 | 245 | 198 |

| Thermal Expansion Coefficient ×10-6 /K | 17.6 | 17.6 | 17.4 | 17.4 | 17.6 | 17.7 | 17.8 | 17.6 | - |

| Poisson's ratio | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 |

Mechanical Properties

| Copper Alloy Name | C7025 | NKC164 | NKC286 | NKC286S | NKC388 | NKC164E | NKC4419 | NKC4820 | NKC1816 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Tensile Strength (MPa) | O | - | - | - | - | - | - | - | - | |

| 1/4H | - | - | - | - | - | 520-650 (600) | - | - | ||

| 1/2H | TR02 607-726 (650) | 560-680 (640) | 710-840 (780) | 730-870 (800) | - | - | - | - | - | |

| H | TM02 650-740 (725) | 620-740 (680) | 760-890 (830) | 800-940 (880) | - | 590-680 (630) | 590-720 (670) | - | - | |

| EH | TM03 680-760 (744) | 680-800 (730) | 810-940 (880) | - | - | 620-760(680) | - | (740) | - | |

| SH | TM04 750-840 (814) | - | - | - | 890-990 (940) | - | - | - | (840) | |

| ESH | TM04S 710-830 (785) | - | - | - | 930-1030 (980) | - | - | - | 840-940 (880) | |

| XSH | - | - | - | 970-1090 (1030) | - | - | - | - | ||

| USH | - | - | - | 970-1090 (1030) TD:1070-1190 (1130) |

- | - | - | - | ||

| 0.2% Yield Strength (MPa) | O | - | - | - | - | - | - | - | - | |

| 1/4H | - | - | - | - | - | 370-500 (480) | - | - | ||

| 1/2H | TR02 550min (575) | 520-670 (610) | 690-830 (760) | 695-835 (765) | - | - | - | - | - | |

| H | TM02 585min (644) | 580-730 (660) | 740-880 (810) | 775-915 (845) | - | 540-680 (610) | 570-700 (650) | - | - | |

| EH | TM03 655min (710) | 640-790 (720) | 790-930 (860) | - | - | 600-740 (670) | - | (710) | - | |

| SH | TM04 740min (800) | - | - | - | 860-960 (910) | - | - | - | (820) | |

| ESH | TM04S 700min (772) | - | - | - | 900-1000 (950) | - | - | - | 810-910 (850) | |

| XSH | - | - | - | 940-1060 (1000) | - | - | - | - | ||

| USH | - - | - | - | - | 940-1060 (1000) TD:1040-1160 (1100) |

- | - | - | - | |

| Elongation (%) | O | - | - | - | - | - | - | - | - | |

| 1/4H | - | - | - | - | - | 10min (17) | - | - | ||

| 1/2H | TR02 6.0min (10.0) | 5min (8.0) | 3min (6.0) | 3min (7.0) | - | - | - | - | - | |

| H | TM02 10.0min (13.0) | 3min (6.0) | 2min (4.0) | 1min (2.0) | - | 5min (12) | 2min (8) | - | - | |

| EH | TM03 5.0min (9.0) | 1min (4.0) | 1min (2.0) | - | - | 2min (5) | - | (3) | - | |

| SH | TM04 1.0min (3.0) | - | - | - | 1.0min (3.0) | - | - | - | 1.0min (3.0) | |

| ESH | TM04S 1.0min (3.8) | - | - | - | 1.0min (2.5) | - | - | - | 1.0min (2.0) | |

| XSH | - | - | - | 1.0min (2.0) | - | - | - | - | ||

| Vickers Hardness (Hv) | O | - | - | - | - | - | - | - | - | |

| 1/4H | - | - | - | - | - | 160-210 (180) | - | - | ||

| 1/2H | TR02 180-220 (204) | 160-230 (190) | 200-270 (230) | 215-285 (250) | - | - | - | - | - | |

| H | TM02 190-240 (215) | 170-240 (200) | 210-280 (245) | 250-320 (285) | - | 160-220 (200) | 180-220 (200) | - | - | |

| EH | TM03 200-250 (235) | 200-270 (220) | 230-300 (260) | - | - | 170-230 (210) | - | (230) | - | |

| SH | TM04 225-275 (248) | - | - | - | 250-310 (280) | - | - | - | (250) | |

| ESH | TM04S 210-260 (246) | - | - | - | 265-325 (295) | - | - | - | (270) | |

| XSH | - | - | - | 285-350 (325) | - | - | - | - | ||

| USH | - | - | - | - | 285-350 (325) | - | - | - | - | |

- Standard specs. (Typical values)

Bend Formability

| Copper Alloy Name | C7025 | NKC164 | NKC286 | NKC286S | NKC388 | NKC164E | NKC4419 | NKC4820 | NKC1816 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Minimum Bend Radius / t Badway |

1/2H | TR02 4.0 | 0.0 | 0.0 | 0.0 | - | - | 1/4H : 0.0 | - | - |

| H | TM02 0.0 | 0.0 | 0.5 | 1.0 <t=0.08mm> | - | 0.0 | 0.7 | - | - | |

| EH | TM03 1.0 | 1.5 | 1.7 | - | - | 0.2 | - | - | ||

| SH | TM04 5.0 | - | - | - | 1.0 | - | - | - | ||

| ESH | TM04S 1.0 <t=0.1mm> | - | - | - | 3.0 | - | - | - | ||

- Bad way 90°W-shape Bending Width=10mm

| Explanation of technical terms |

|---|

Inquiries accepted 24 hours a day.