Under DevelopmentSurface Treated Copper Powders for Additive Manufacturing (AM)

These are advanced functional copper powders applying our state-of-the-art surface treatment technology.

For L-PBF (Laser Powder Bed Fusion), surface treatment improves manufacturability, as well as achieving high density along with electrical conductivity and thermal conductivity equivalent to pure copper.

For EB (Electron Beam) AM, The surface treatment exhibits the powder sintering inhibition effect during the pre-heating process. Such an effect allows us to increase flexibility of AM processing.

Applications

Copper Powder for L-PBF (Laser Powder Bed Fusion)

Our proprietary surface-treated high-performance copper powder enables molding with high density, high electrical conductivity and high thermal conductivity equivalent to pure copper.

Our surface treated copper powder enables building with high density and high electrical conductivity at laser output power of 400W or 500W, which is impossible with untreated pure copper powder. In addition, since our surface treated copper powders do not require post heat treatment to obtain high electrical conductivity as required with CuCrZr or other copper alloy powders.

| Our coated copper powder | Pure copper | CuCrZr copper alloy powder | |

|---|---|---|---|

| Laser outputs | 400, 500W | 400, 500W | 400, 500W |

| Electrical conductivity | ≧99%IACS*1 | 80%IACS*1*2 | 80%IACS*1 |

| Post heat treatment | Not required | Required | Required |

- *1Values confirmed in our own testing.

- *2When pure copper powder without surface treatment is used in additive manufacturing, many bubbles can form due to incomplete powder melting or sintering, inevitably reducing the density and conductivity of the formed object.

3D Printed Object using JX Advanced Metals L-PBF copper powder

Water cooled cold plate (manufactured by Alloyed Ltd. [UK])

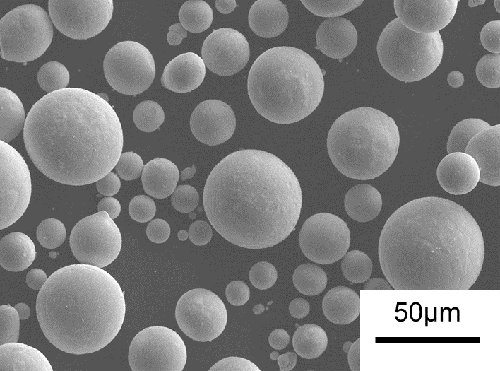

SEM cross-sectional image of formed product.

Enables high-density builded with few defects.

Copper Powder for EBM(Electron Beam Melting)

The effectiveness of the surface treatment in inhibiting powder sintering during preheating process facilitates powder removal, enabling more detailed and complex processing, especially of hollow shapes. Another benefit of inhibiting powder sintering during preheating is shortening of the time for removing a formed object from the printer, for improved productivity. Surface treatment also has anti-oxidation benefits, preventing a rise in oxygen level that can inhibit processing.

Anti-oxidation effect

Typical Properties of Surface Treated Copper Powders for Additive Manufacturing

| LB Grade | EB Grade | |

|---|---|---|

| Avg. particle diameter | 30 – 45 µm | 65 – 85 µm |

| Particle size distribution | 53μm>90%, +53μm≦10 |

53μm≦20%, +53μm/-106μm>70%, +106μm≦10% |

Inquiries accepted 24 hours a day