Copper Titanium Alloy

C1990-GSH(HP) - Copper Titanium Foil

Overview

- A Hyper copper titanium foil (model code C1990(HP)) offering the highest level of strength of any copper alloy.

- The high strength and excellent spring properties make it an alternative to beryllium copper foil.

- Higher thickness precision than conventional materials is achieved by optimizing the manufacturing processes.

This higher thickness precision in turn improves the stability of spring properties. - All production processes from metal melting to product-width slitting take place in our Kurami Works, enabling quick delivery time.

Features

- High strength

- Excellent spring properties

- Can be used in place of beryllium copper

- High thickness precision

- High reliability

- Excellent stress relaxation resistance

- Excellent fatigue properties

- Full-process production for quick delivery

Manufacturable thickness (typical dimensions)

- 30µm~100µm

- Maximum width 450 mm

Typical applications

- Connectors

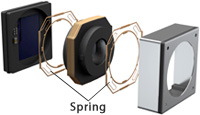

- Spring material in autofocus camera modules for mobile phones

Table 1. C1990-GSH(HP) chemical composition (%)

| Cu | Ti | |

|---|---|---|

| Standard composition | Remainder | 3.0 |

Table 2. Physical properties of C1990-GSH(HP)

| Electrical conductivity | 8 | %IACS (@20℃) |

|---|---|---|

| Specific resistivity | 216 | nΩ·m (@20℃) |

| Thermal conductivity | 39 | W/mK |

| Linear expansion coefficient | 18.6 | ×10-6/K(20 to 300℃) |

| Modulus of elasticity | 127 | GPa |

| Specific gravity | 8.70 |

Table 3. Mechanical properties of C1990-GSH(HP)

(upper: typical values, lower: specification range)

| Temper | Tensile strength (MPa) |

Yield Strength (MPa) |

Vickers hardness (Hv) |

|---|---|---|---|

| C1990-GSH(HP) | 1400 1300-1600 |

1390 - |

400 - |

Figure 1. Histogram of thickness distribution in the longitudinal direction (comparison of high thickness precision material with conventional material; thickness 30µm)

- Data obtained by X-ray measurements of thickness at the center of the transverse direction (perpendicular to the rolling direction) of the mother coil, taken every 0.01 seconds for approximately 1,000 meters.

- The values shown are typical values and are not intended as specifications.

Figure 2. Thickness distribution in the transverse direction (high thickness precision material N = 3, thickness 30 µm)

- Thickness distribution was measured in the transverse direction using a direct contact thickness gauge.

- The values shown are typical values and are not intended as specifications.

Contact Information

From the Web

Inquiries accepted 24 hours a day.