Resource Recycling

The Group aims to achieve resource recycling across the entire supply chain by efficiently developing and producing a diverse range of products from limited resources without waste, while promoting recycling to reduce environmental impact.

Sustainable Copper Vision

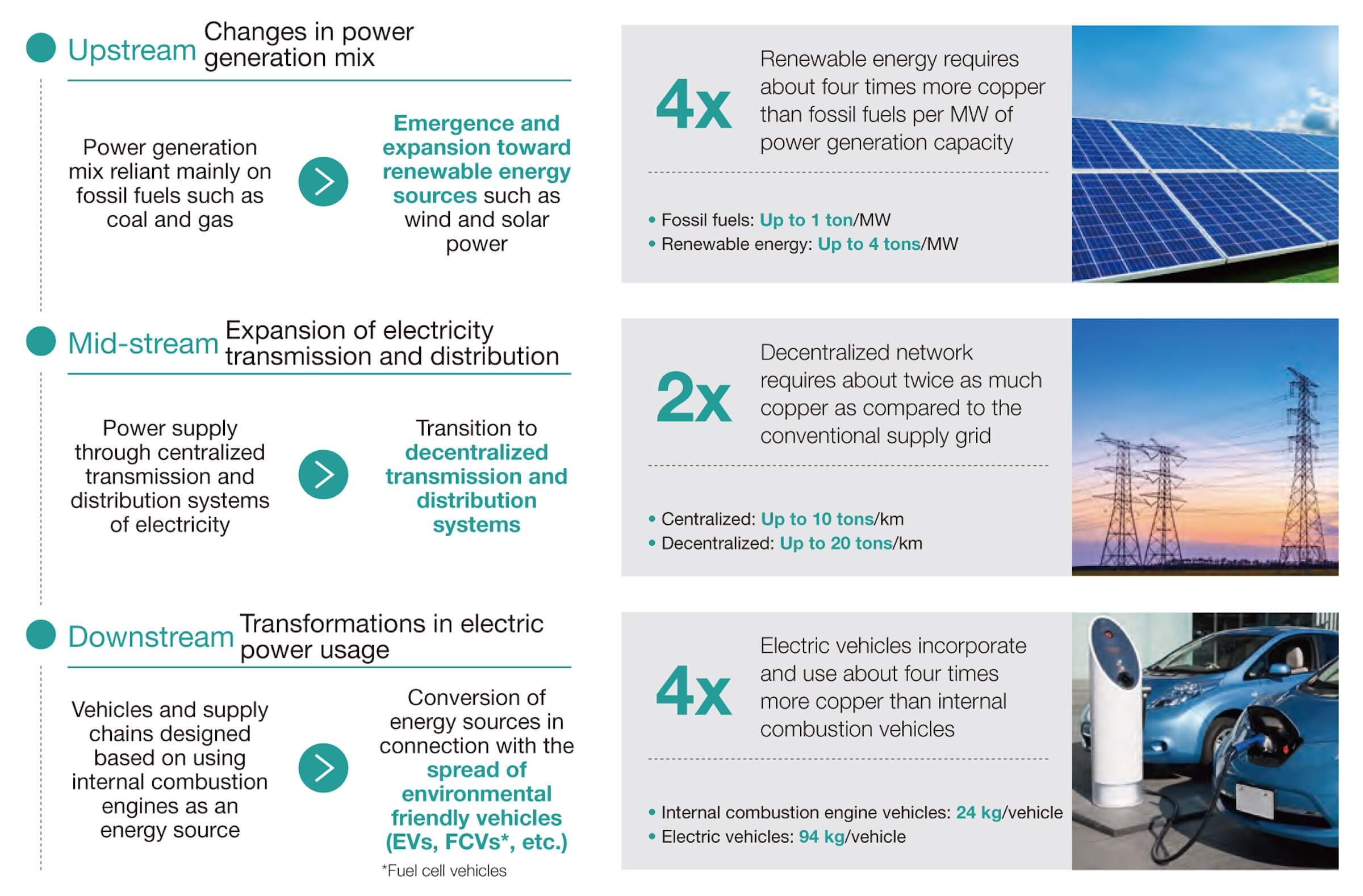

Why is Copper So Important?

Copper is a decarbonization resource indispensable for achieving carbon neutrality. Both producers and users can serve as enablers of a greener future, or Green Enablers. At the same time, we must minimize the environmental impact associated with the production of copper and ensure that the supply is sustainable.

How Does JX Advanced Metals Produce Sustainable Copper?

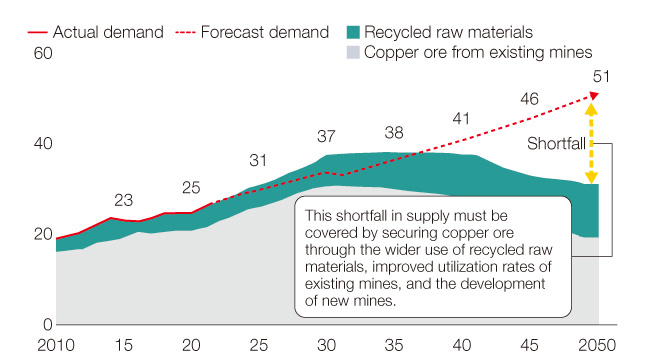

Projected Future Demand by Source (Refined Copper, Units: Millions of tons)

Demand for copper is expected to grow over the long term. For this reason, not only will it be difficult to meet copper demand through recycling alone, but the market will likely face supply shortages , even when adding the supply from existing mines. Accordingly, it is essential that we utilize both copper ore and recycled materials, in addition to expanded recycling, if we are to meet the essential copper demand required for global decarbonization.

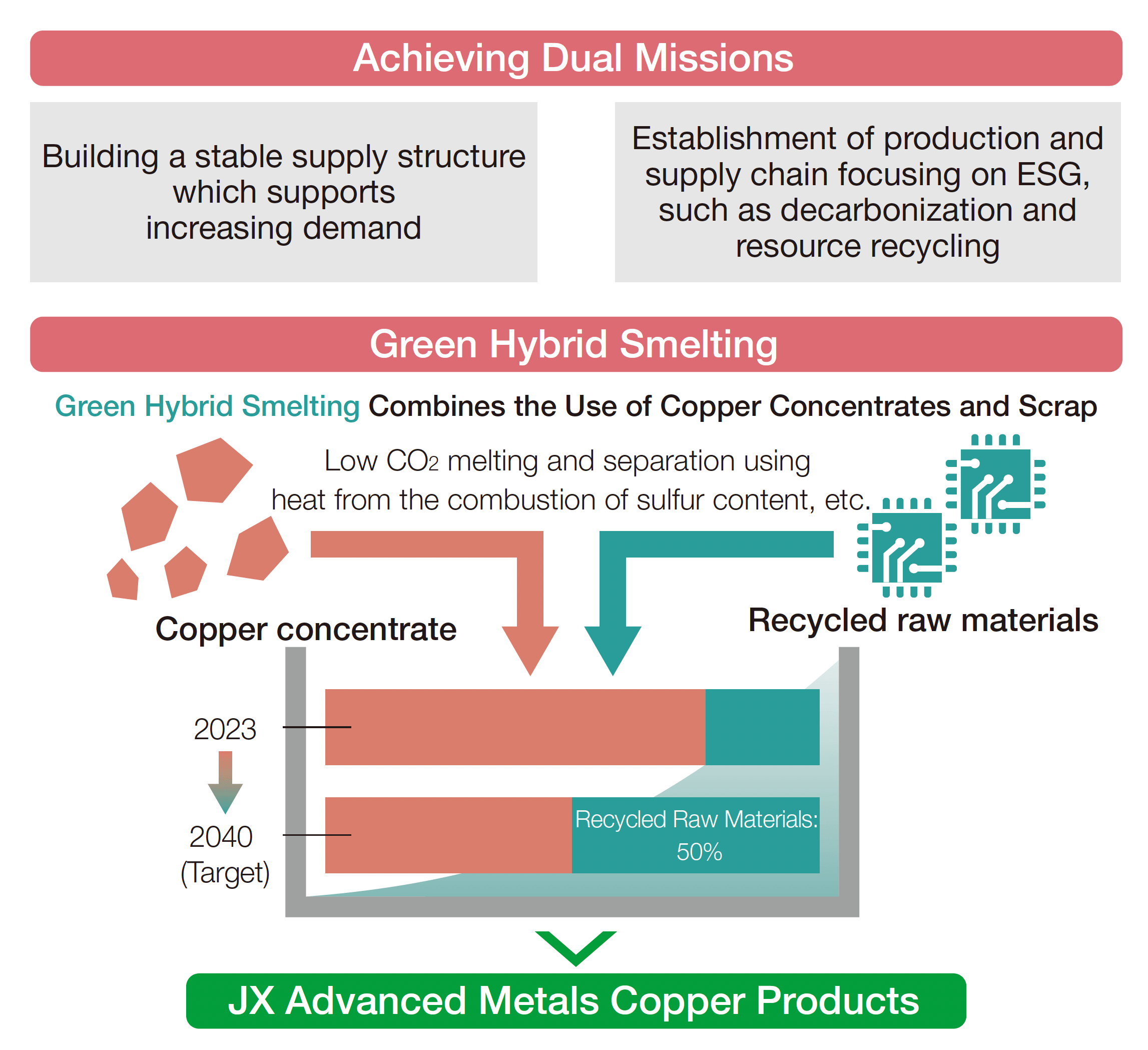

Green Hybrid Smelting Achieves Dual Missions

JX Advanced Metals produces electrolytic copper through a process we call Green Hybrid Smelting. This process allows us to use both copper concentrates and recycled materials as feedstock. The heat generated from the oxidation of sulfur and iron contained in the copper concentrates facilitates the melting of recycled materials. In this way, we minimize the use of fossil fuels compared to other smelting methods.

Green Hybrid Smelting has been selected as one of the 26 most noteworthy examples of Japan's circular economy initiatives in Case Studies (2022) published by the Japan Partnership for Circular Economy, which was established by the Ministry of the Environment, the Ministry of Economy, Trade and Industry, and Keidanren.

The JX Advanced Metals Approach to Sustainable Copper

Initially, JX Advanced Metals considered sustainable copper to be copper capable of both decarbonization and resource recycling. However, prioritizing decarbonization or resource recycling to an excessive degree—causing copper to become inordinately expensive or scarce—may not only hinder society from achieving decarbonization, but could also stand in the way of the maintenance and development of modern society, where electric power and telecommunications infrastructure are becoming increasingly essential. This development, in turn, could pose the risk of lowering standards of living.

Therefore, we modified our definition of sustainable copper to include ensuring stable supply and economic viability. The JX Advanced Metals Group aims to establish a copper supply structure capable of balancing all three elements equally.

Measures to Ensure Sustainable Copper

-

1.Reduce CFP [Decarbonization]

- Make CFP calculations and acquire third-party assurances

- Convert construction equipment used in mines to electric power

- Use electricity derived from renewable sources

- Improve efficiencies and optimize transportation, etc.

-

2.Increase Recycling Ratios [Decarbonization, Resource Recycling]

- Develop technologies to increase the ratio of recycled raw materials

- Increase efficiency and optimization of transportation by means including expanding the capacity of facilities for the increased collection of recycled materials, etc.

-

3.Promote Responsible Procurement and Other Measures [Stable Supply and Economic Viability]

- Pursue measures that consider and encourage global environmental conservation, human rights, and contributions to local communities

- Acquire Copper Mark and other certifications that meet ESG standards set by the International Copper Association (ICA)

-

4.Form Green Enabling Partnerships [Decarbonization, Resource Recycling, Stable Supply and Economic Viability]

- Form partnerships with companies that work together to promote sustainable copper, and accelerate the transition to decarbonized and circular economies

- Engage in product and scrap collection, raw materials reuse, and joint technology development with partners, etc.

-

5.Supply a Stable Volume of Recycled Electrolytic Copper Using the Mass Balance Method [Stable Supply and Economic Viability]

- Maximize the use of existing smelting facilities

- Trace products (electrolytic copper) to source materials

1. Reduce CFP

Acquiring Third-Party Assurance for Electrolytic Copper CFP

JX Advanced Metals operates the first copper smelter in Japan to obtain third-party assurance for the CFP (carbon footprint of products) calculation results related to electrolytic copper. We not only publish the CFP results internally, but also conduct a detailed analysis to ensure we translate findings into concrete measures for reducing CFP.

For example, our analysis revealed that the stage with the greatest impact on the CFP of electrolytic copper is raw materials procurement—particularly the production and transportation of copper concentrates. Accordingly, we launched initiatives such as those described in 2. Increase Recycling Ratios.

We received recognition for our initiatives in January 2025 with the Chairman’s Award at the 21st LCA Japan Forum.

We are also looking into measures to improve transportation fuel efficiency and the use of plant-derived fuels. At the same time, we continue discussions with major resource companies through the framework of the Green Enabling Partnership to achieve resource extraction decarbonization as quickly as possible.

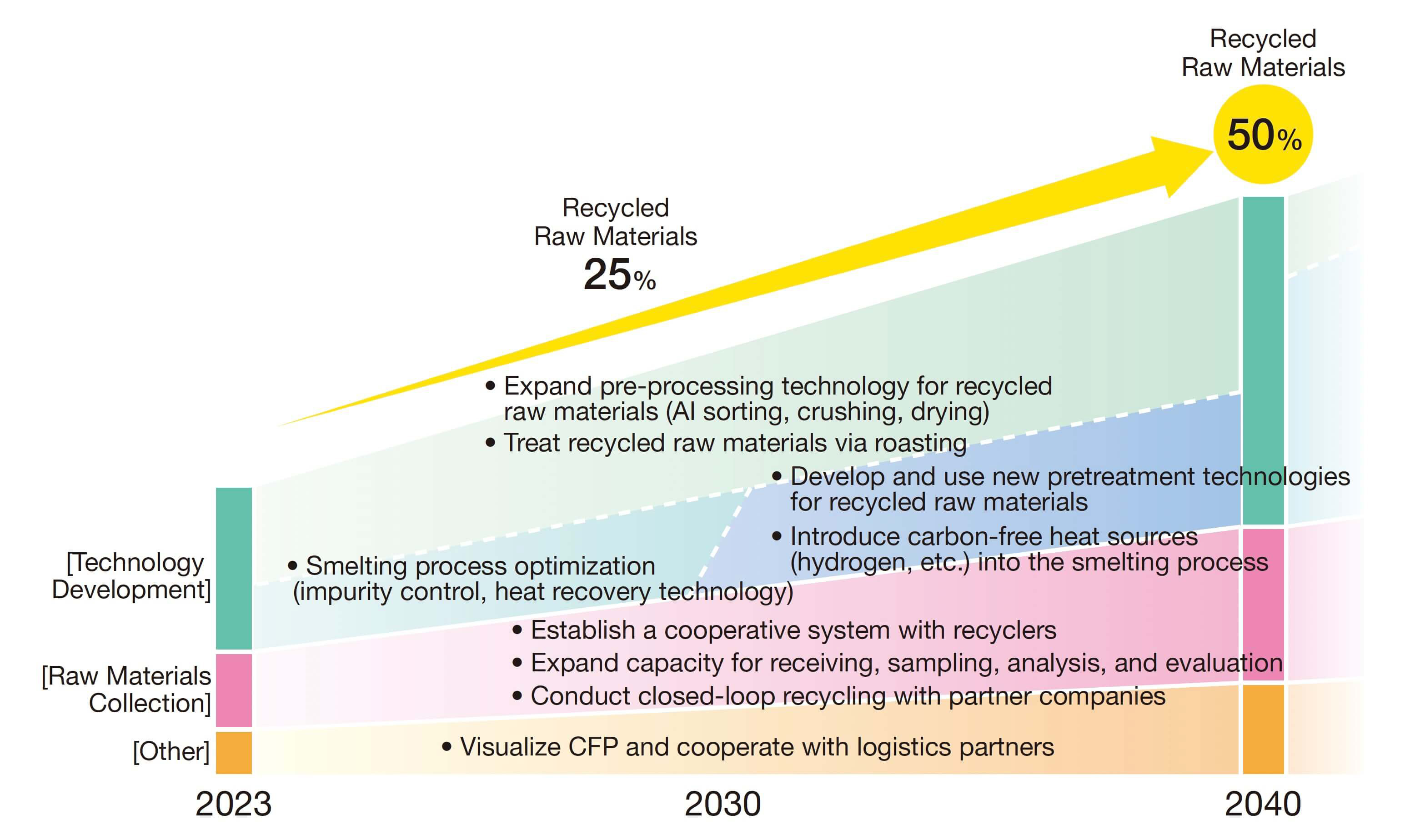

2. Increase Recycling Ratios

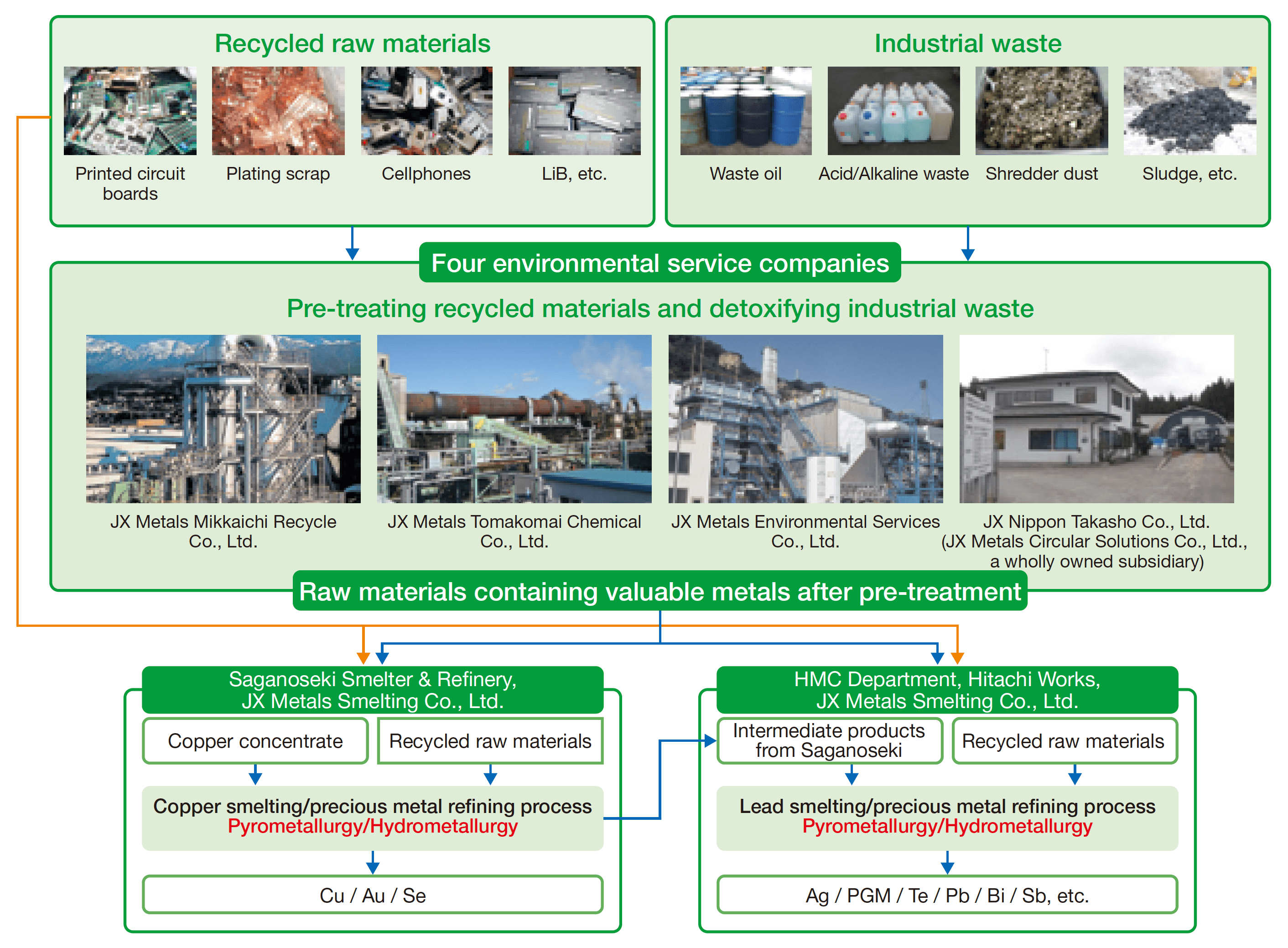

Expanding Our Recycled Resource Procurement Network

We pursue the optimal combination of sustainable mineral resource development/production and recycling, aiming to achieve a recycled-resource ratio of 50% or more by 2040 (proportion of recycled resources vs. total inputs or proportion of recycled resources in final product).

We engage in the following activities to expand our network for procuring recycled resources both in Japan and overseas.

- In August 2022, we acquired all shares of eCycle Solutions Inc., a Canadian recycler, and we began collaborations with Sojitz Corporation in April 2023.

Reference: (link) https://www.jx-nmm.com/english/newsrelease/fy2022/20230213_02.html - In April 2024, we established JX Metals Circular Solutions Co., Ltd. in partnership with Mitsubishi Corporation to encourage the reuse of waste home appliances, waste electronic devices, end-of-life automotive lithium-ion batteries, and other materials. The new venture began operations in July of the same year.

Reference: (link) https://www.jx-nmm.com/english/newsrelease/fy2024/20240701_02.html

Green Hybrid Smelting Roadmap

3. Promote Responsible Procurement and Other Measures

The Copper Mark Certification

The Saganoseki Smelter & Refinery and Hitachi Works are engaged in responsible production activities. In December 2022, these facilities were the first in Japan to receive The Copper Mark, a highly credible assurance framework that demonstrates the copper industry's commitment to the green energy transition.

The Copper Mark is a certification program established in 2019 requiring compliance with 32 standards, including standards for the environment, human rights, community, and governance. Both of the business sites will continue to undergo evaluations based on the various standards established under The Copper Mark.

In October 2023, the Caserones Copper Mine (Chile), in which we hold a partial interest, obtained The Copper Mark. With this certification, all concession-holding copper mines and copper smelting and electrorefining plants are now certified. As international demands for sustainability initiatives increase, we will continue efforts to strengthen the competitiveness of sustainable businesses.

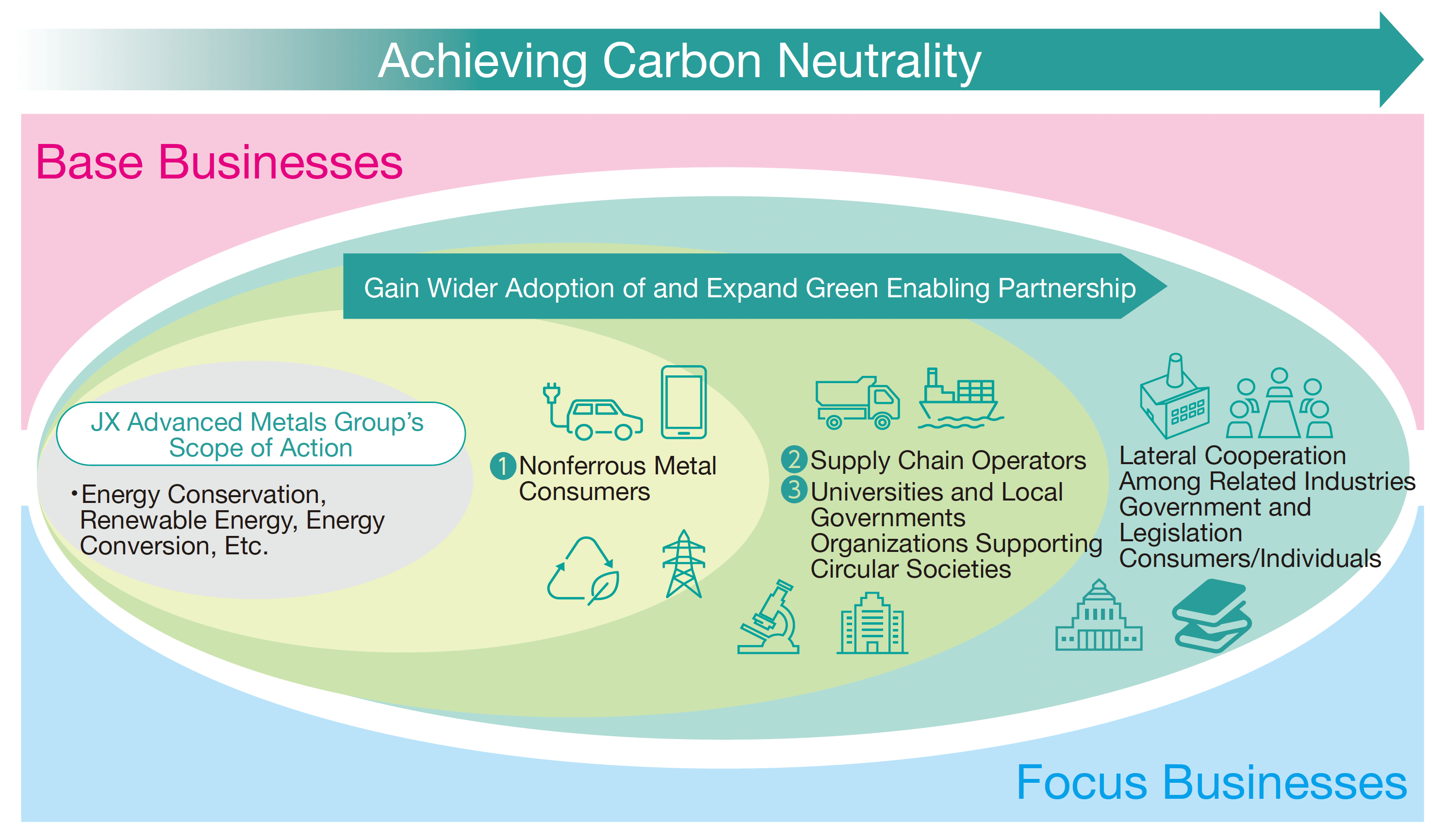

4. Form Green Enabling Partnerships

Partnerships Toward Circular Economies

We form Green Enabling Partnerships (GEP) with companies who work together to promote sustainable copper. Through these partnerships, we accelerate the transition to decarbonized, circular economies, as well as engage in product and scrap collection, raw materials reuse, and joint technology development. Through GEP, we engage in communication with diverse stakeholders and gather feedback on their needs, resulting in the initiatives such as those outlined below.

Green Enabling Partnerships Concept

5. Supply Electrolytic Copper Produced Using the Mass Balance Method

A New Recycling Mechanism

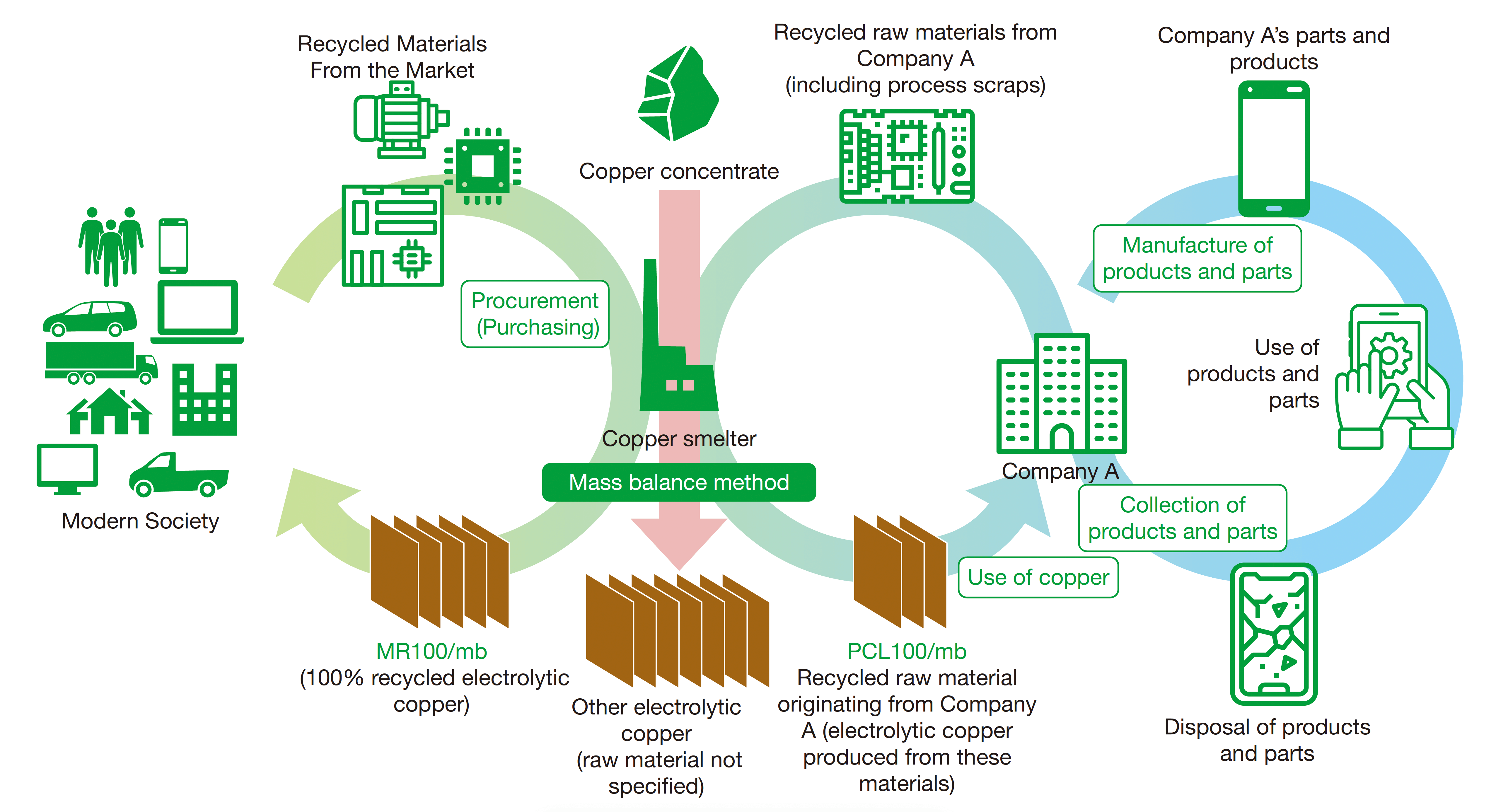

In order to promote resource recycling, it is essential that we not only promote our own initiatives as an individual company, but also cooperate with our customers (including manufacturers of products that use copper) and consumers of final products. By proposing new recycling schemes that are attractive and reliable for users, we can achieve a balance between corporate activities and resource recycling. To that end, we proposed a new copper supply scheme with the aim of co-creating resource recycling with our customers.

Proposing a New Model for 100% Recycled Electrolytic Copper

In January 2024, we announced the launch of two types of 100% recycled electrolytic copper using the mass balance method: The Partnered Closed Loop 100% mass balance method (PCL100/mb) and the Mixed Recycle 100% mass balance method (MR100/mb),” which will be launched during fiscal 2024.

One of the new schemes, the PCL100/mb , involves using recycled materials from customers (Company A in the diagram) that have collected used products or generated process scrap in their factories. The product is returned to customers as 100% recycled electrolytic copper with a guaranteed origin (which means to ensure the copper is sourced from Company A).

In the actual copper smelting process, recycled raw materials from Company A are mixed with other recycled raw materials and copper concentrate for smelting treatment. This practice makes it impossible to extract only copper originating from recycled raw materials from Company A. However, by using the mass balance method, it is possible to link the electrolytic copper to the recycled material. We accurately analyze the volume of copper contained in the recycled materials from Company A and strictly manage the electrolytic copper produced to ensure the content does not exceed that amount, thereby designating the product as copper sourced from Company A. In July 2024, the validation of this management system (CoC management system) was completed by a third party.

On the other hand, in the case of MR100/mb, the origin of the raw material is not separately linked to the electrolytic copper. The management of the recycled materials collected from the market and their copper content will enable us to supply 100% recycled electrolytic copper using the mass balance method.

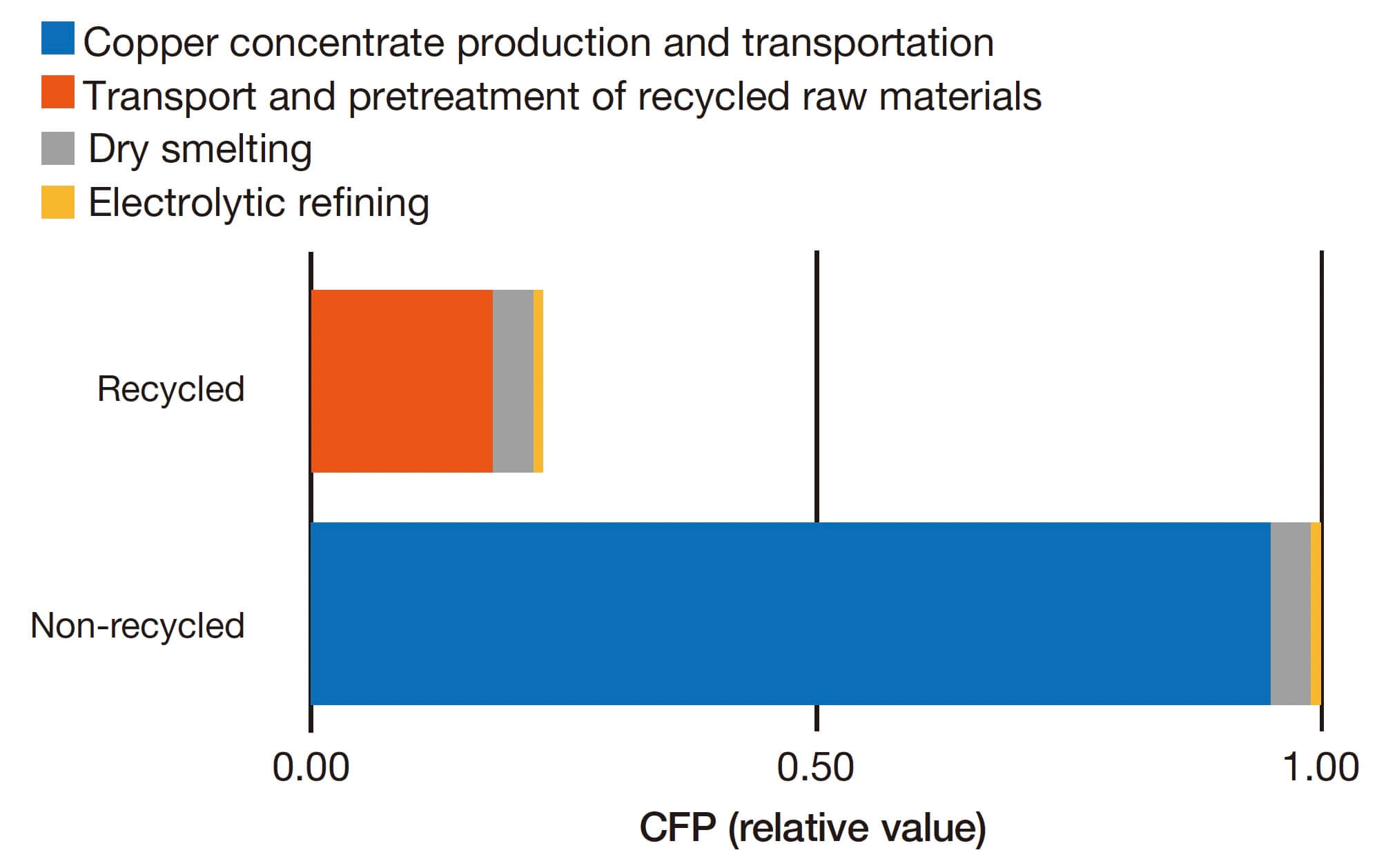

Carbon Footprint (CFP) of Recycled Electrolytic Copper

Electrolytic Copper CFP and Breakdown

We calculate the CFP of electrolytic copper using the mass balance method, generating internal calculations. We have determined that the greatest impact related to electrolytic copper CFP comes at the raw material procurement stage—particularly during the production and transportation of copper concentrate.

However, assuming the use of recycled electrolytic copper, which does not use copper concentrate, for CFP, we expect to eliminate emissions arising from processes such as the production and transportation of copper concentrate. In this case, we calculate the CFP of recycled products to be no more than 25% of the non-recycled product, even after factoring in the emissions associated with the incineration of plastics attached to certain recycled materials.

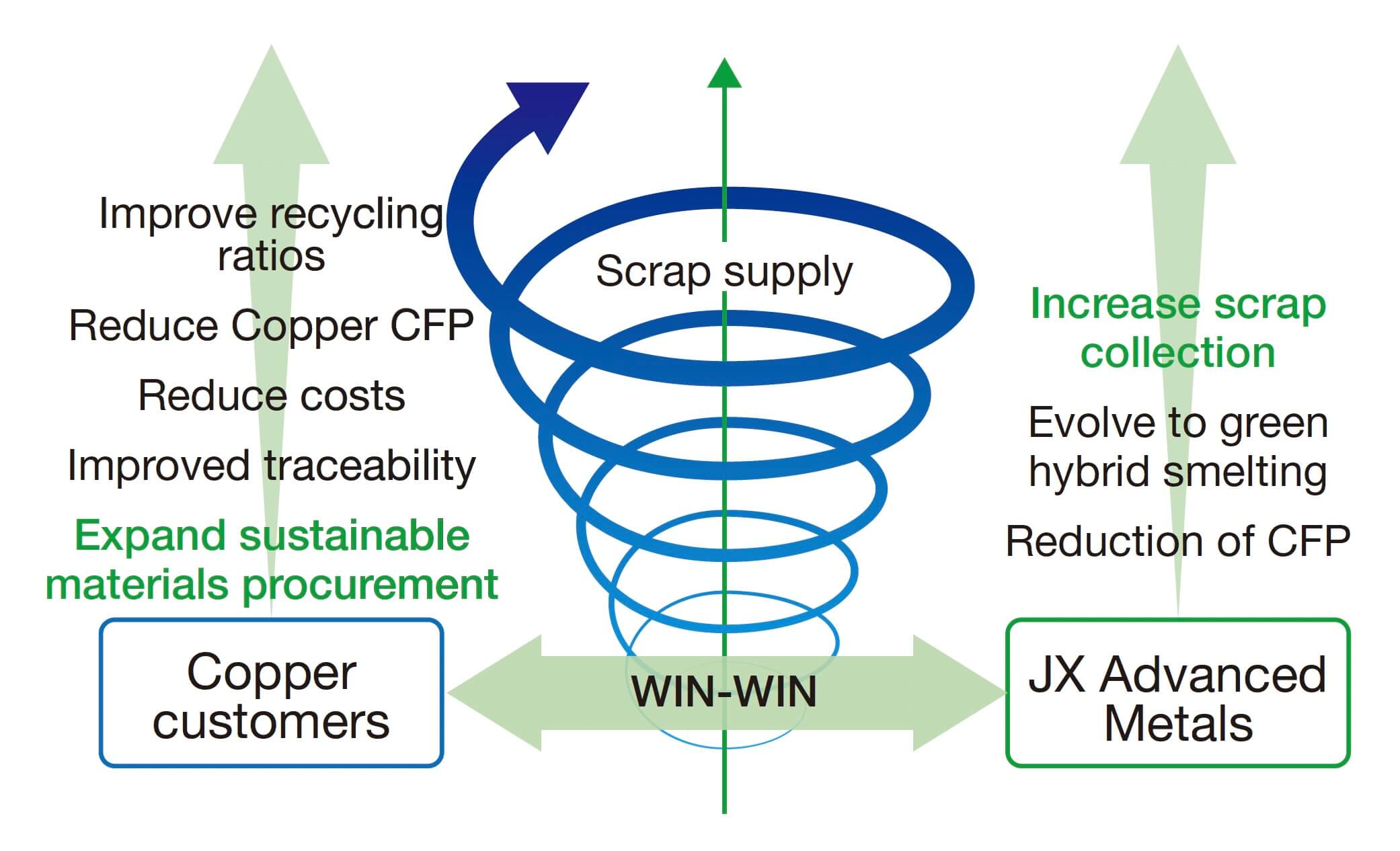

Spiral Model With Partner Companies

The combination of increasing recycling ratios and utilizing mass balance methods can produce a variety of benefits. PCL100/mb, for example, contributes to our ability to secure a stable supply of recycled raw materials with the cooperation of our customers. There are benefits for customers (copper consumers) as well, such as the potential to obtain recycled electrolytic copper at quality and cost levels similar to traditional materials, improved raw material traceability, and a reduction in the CFP of procurement materials. Moreover, focusing on the collection of waste products and process scrap produced by customers, which serve as the raw materials for PCL100/mb, not only facilitates the procurement of recycled electrolytic copper, but also has the potential to contribute to the promotion of resource recycling throughout society. In this way, our proposed model for supplying 100% recycled electrolytic copper provides various benefits through interaction between our customers and us, fostering a win-win relationship.

We pursue the social implementation of 100% recycled copper products under the product series name Cu again. This product name reflects our hope that, after completing its role in society and returned as scrap, copper (Cu) will be recycled and used again to support society in the future.

Through co-creation with customers, we intend to expand the Cu again product lineup in the further pursuit of resource recycling and decarbonization throughout society.

Spiral Model With Partner Companies

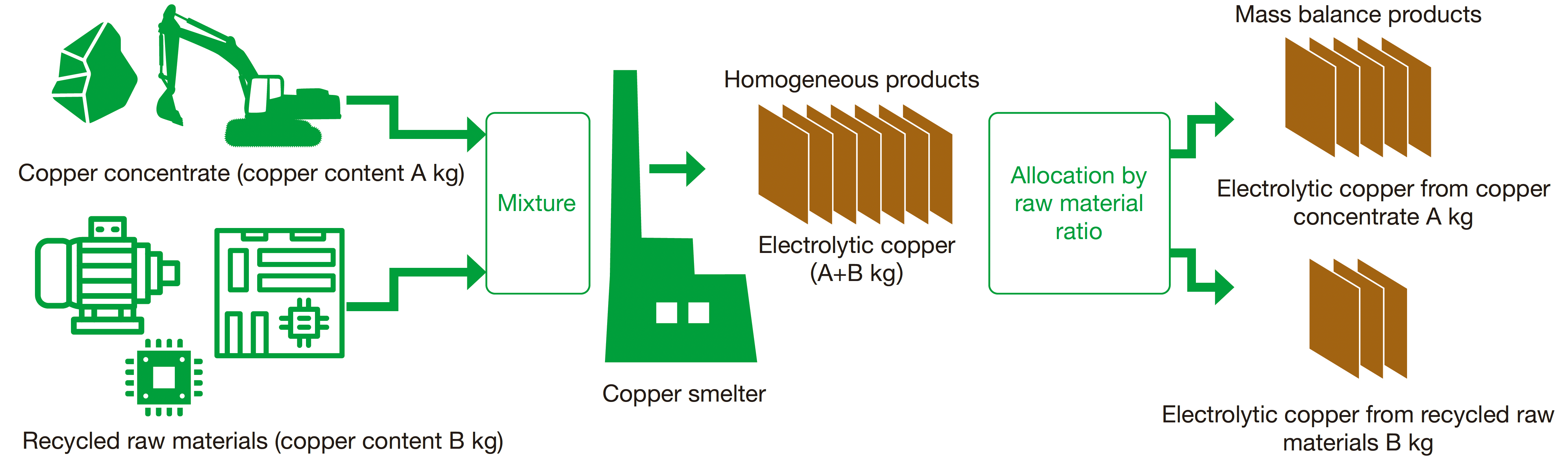

Mass Balance Method Concept

The mass balance method is used when raw materials with differing properties and origins are mixed during the manufacturing process, resulting in products that cannot be distinguished based on their raw materials. This approach allocates specific properties to a portion of the product based on the input ratio of raw materials with those properties.

Example of Mass Balance

Other Initiatives for Environmental Conservation

High-Performance Copper Alloy Products From 100% Recycled Resources

Traditionally, we have made the high-performance copper alloy products manufactured at our production sites using electrolytic copper together with high-purity recycled materials generated either in the market or within our own facilities. In January 2025, we announced our launch of high-performance copper alloy products made with 100% recycled raw materials under the Cu again project as a measure to meet the growing need for products manufactured solely from recycled materials.

We manufacture these products in a different manner than electrolytic copper, using equipment that prevents the inclusion of copper derived from copper concentrate.

Our first offerings in this product lineup incorporate strip and foil products made from copper titanium alloys and Corson alloys. We regenerate these products into high-performance copper alloy materials, using recycled raw materials collected with the cooperation of JX Advanced Metals Group companies, combined with proprietary impurity-separation and impurity-suppression technologies.

We received third-party assurance for the products from UL Solutions (UL2809) as proof of manufacture using 100% recycled raw materials and ensuring a high level of reliability.

Our copper titanium and Corson alloys are widely used in smartphone camera units, next-generation communication devices, and connectors within electric vehicles. In this way, we support both the expansion of the information society and decarbonization.

Today, demand is increasing rapidly for these materials as highly reliable connector materials used inside generative AI data centers. We also expect adoption to grow in developing fields, including next-generation wearable devices, mobility, and industrial robots. In the future, we will expand our product lineup in this area and propose new products to customers across a broad range of sectors that demand environmentally conscious advanced materials.

Reference:https://www.jx-nmm.com/english/newsrelease/fy2024/20250114_2.html

Closed-Loop Recycling of Automotive Lithium-Ion Batteries (LiB)

Minor metals such as nickel, cobalt, and lithium used in LiB are not produced in Japan, but are rather concentrated in a specific set of countries and regions. Reducing the environmental impact and supply chain risk associated with the use and securing of these mineral resources has become a serious social issue.

In 2020, we established a closed-loop recycling process to recover minor metals from end-of-life automotive LiBs, reusing these metals as raw materials for automotive LiBs in continuous processing bench-scale test equipment installed at Hitachi Works. Scaled-up versions of this process are being gradually introduced at JX Metals Circular Solutions Tsuruga Co., Ltd. In addition to the inauguration of a high-purity nickel sulfate recovery facility in 2021 and a high-purity cobalt sulfate recovery facility in 2022, we have started operations for a high-purity lithium carbonate recovery facility in April 2023, and are demonstrating our recycling process there. Going forward, we will provide high-purity recycled metal salts to our business partners and demonstrate closed-loop recycling for automotive LiB through the supply chain.

In 2022, our project for the Development of Technology for Closed-Loop Recycling for Automotive LiB was selected for funding by the Green Innovation Fund of the New Energy and Industrial Technology Development Organization (NEDO). Utilizing this fund, we will further advance recycling technology toward the social implementation of closed loop recycling for automotive LiB in collaboration with universities and public research institutions.

In 2024, we established JX Metals Circular Solutions Co., Ltd. in partnership with Mitsubishi Corporation. This new company focuses on resource recycling for non-ferrous metals found in waste home appliances, waste electronic devices, end-of-life automotive lithium-ion batteries, and similar materials.

We transferred our copper and precious-metal recycling business to JX Metals Circular Solutions in addition to our automotive lithium-ion battery recycling business, which was previously under the Company and our wholly owned subsidiary, JX Metals Trading Co., Ltd.

JX Metals Circular Solutions is committed to creating a circular economy by focusing on resource circulation for end-of-life home appliances, electronic devices, and automotive lithium-ion batteries. In this way, the company provides solutions to the challenges faced by automotive OEMs, major electronics manufacturers, and other entities.

Acquisition of Certification for Recycling and Reuse Operators Under the Basel Act

The JX Metals Smelting Co. Ltd., Saganoseki Smelter & Refinery received certification as a recycling and reuse operator under the Law for the Control of Export, Import, and Others of Specificized Hazardous Wastes and Other Wastes (Basel Act) on August 23, 2023.

The so-called Basel Act establishes rules to ensure the precise and smooth implementation of the Basel Convention, the international framework for regulating the transboundary movement and disposal of waste. Recycling and reuse operators are business operators that are able to recycle and reuse waste appropriately and in a manner that preserves the environment. The recent certification indicates that the efforts in the Metals & Recycling Business at the Saganoseki Smelter & Refinery have been evaluated as meeting the requirements for certification.

Initiatives for Zero Emissions

In general, smelting, refining, and recycling businesses bury secondary waste (incinerated ash, incineration residue, etc.) generated during the treatment of industrial waste as the final method of disposal. Pursuing the notion of never discard, never bury , the JX Advanced Metals Group strives for zero emissions by combining our environmental and recycling businesses to build and operate a system to recycle these secondary wastes and the valuable metals contained therein. Affiliated companies involved in our Environmental Business work with the Metals and Recycling Business sites to achieve a recycling-oriented society.