Quality Control in the Supply Chain

The JX Advanced Metals Group recognizes that our social mission is to provide a stable supply of nonferrous metals and advanced materials to contribute to the sustainable development of society. Based on this policy, we aim to improve the level of quality control throughout the entire supply chain.

JX Advanced Metals Group Basic Quality Policy

We, the JX Advanced Metals Group, will strive to ensure and improve quality in accordance with the following policy in the pursuit of excellence in order to create value for society through our products, technology, etc.

- 1.We will correctly grasp the requirements of customers and society in order to offer products and services that customers will trust and be satisfied with.

- 2.While paying due attention to safety and environmental conservation, we will improve quality at all processes from development, designing, order acceptance, and delivery to after-sale services.

- 3. We will establish a quality management system, and carry out continual improvements and train human resources.

- 4.We will comply with all pertinent laws of both Japan and overseas countries, and offer to customers and society transparency with regard to quality.

- Established on 1 July 2010

Revised on 1 November 2025

Establishing and Operating a Quality Management System

The Group established a quality management system (QMS), which we operate to carry out our Basic

Quality Policy. We work to continually make quality improvements through steady PDCA cycles, aiming to

realize better quality through the QMS. As one measure, Company sites both in Japan and overseas have

acquired QMS third-party certification (ISO 9001, etc.).

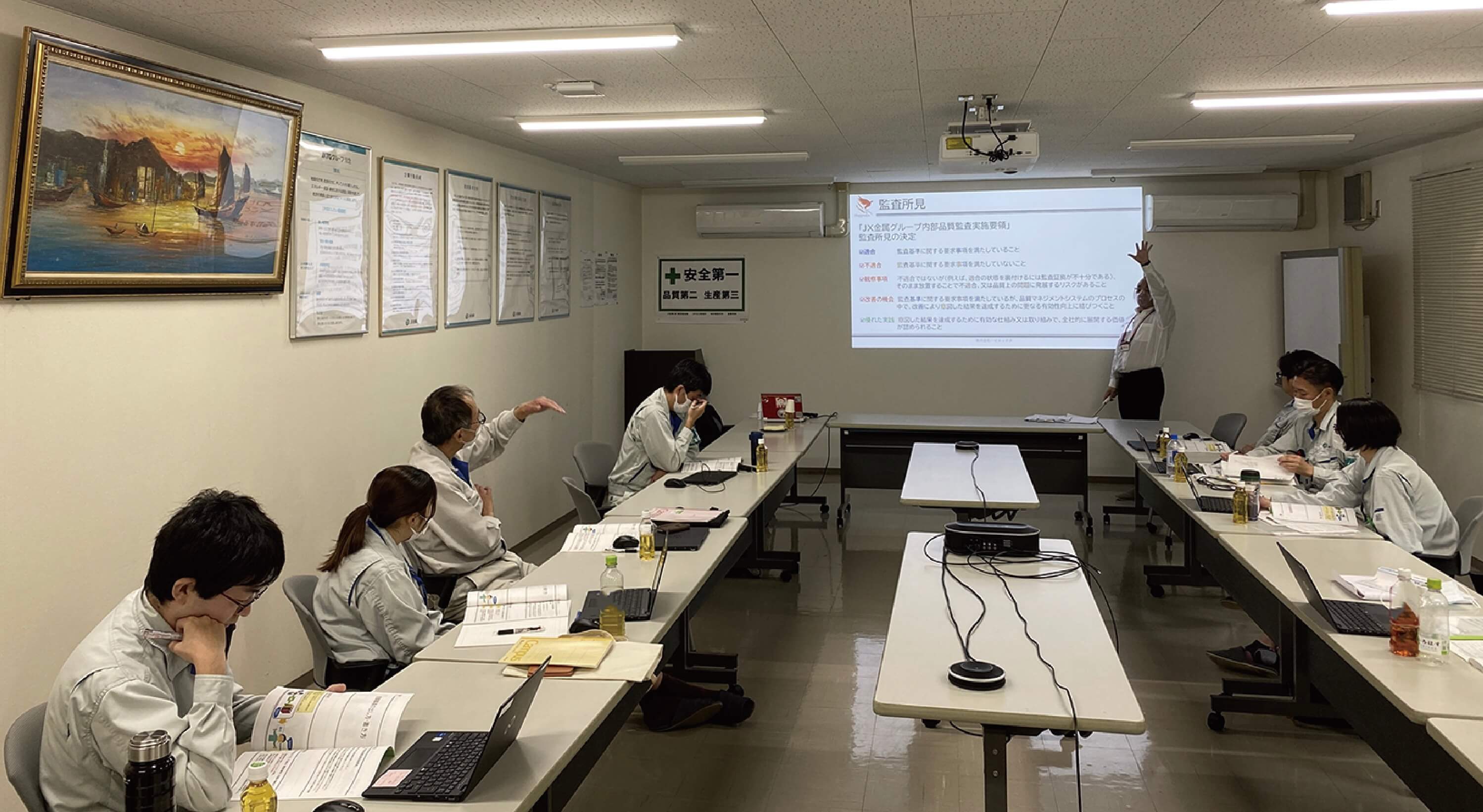

In addition, the Group reviews quality improvement activities and establishes action plans through the

Quality Management Meeting, which is attended by top management. We also hold meetings with the

persons in charge of quality twice annually to share information on quality management. Participants

share the action plans adopted at Quality Management Meetings and share issues encountered and good

practices found at each manufacturing site, fostering interactions among managers. Furthermore, we are

working to improve the effectiveness of internal quality audits, automate inspections, and strengthen

the training of quality control personnel.

Our efforts to strengthen human resources development included introducing the OEA Program offered by

the International Register of Certificated Auditors (IRCA). This program is the only system in the

world on its kind, designed to train quality audit professionals to meet global standards. The JX

Advanced Metals Group focuses on improving our quality management system (QMS), not only for product

quality, but also across all business processes, placing importance on internal audit effectiveness.

We aim to double our number of professional quality auditors through the OEA Program by 2027.

Currently, we have a total of 11 employees evaluated by and registered with IRCA under its

international standards, including 2 Lead Auditors, 2 Auditors, 4 Internal Auditors, and 3 Associate

Auditors. We define those working as Auditors or higher-level positions as Professional Quality

Auditors.

These initiatives support the JX Advanced Metals Group long-term vision to become a global leader in

advanced materials. We will continue to improve our QMS to help drive innovation and contribute to

social progress.

JX Advanced Metals Group Basic Policy on Procurement (Excerpt)

[Domestic]

- Isohara Works, Kurami Works, Hitachi Copper Foil Works

- Ichinoseki Foil Manufacturing Co., Ltd.

- Kitaibaraki Precision Co., Ltd.

- JX Advanced Metals Coil Center Co., Ltd. (Kurami Office and Tatebayashi Office)

- JX Metals Trading Co., Ltd. (Takatsuki Plant)

- JX Metals Smelting Co., Ltd. (Saganoseki Smelter & Refinery and Hitachi Works)

- JX Metals Smelting Logitech Co., Ltd.

- JX Metals Resources Exploration & Development Co., Ltd.

- TATSUTA Electric Wire and Cable Co., Ltd. (TATSUTA Technical Center, Kyoto Works, Sendai Works, Tokyo Branch, Head Office and Osaka Works, and Tatsuta Environmental Analysis Center Co., Ltd.)

- Tatsuta Tachii Electric Cable Co., Ltd. (Head Office, Hyogo Works)

- TANIOBIS Japan Co., Ltd. (Head Office, Mito Plant)

- Chugoku Electric Wire & Cable Co., Ltd.

- Tokyo Denkai Co., Ltd.

- Toho Titanium Co., Ltd. (Head Office and Chigasaki Plant; Hitachi Plant; Yahata Plant; Wakamatsu Plant; and Kurobe Plant)

- Japan Copper Casting Co., Ltd. (Saganoseki Plant)

- Furuuchi Chemical Corporation

[Overseas]

- Nippon Mining & Metals (Suzhou) Co., Ltd.

- JX Metals Dongguan Co., Ltd.

- Shanghai TATSUTA Co., Ltd., Suzhou Technical Center

- Nikko Metals Taiwan Co., Ltd. (Longtan Works and Kuanyin Works)

- Changzhou TATSUTA Chugoku Electric Wire & Cable Co., Ltd.

- JX Metals Philippines, Inc.

- JX Advanced Metals USA, Inc.

- JX Advanced Metals Korea Co., Ltd.

- Materials Service Complex Malaysia Sdn. Bhd.

- Materials Service Complex Coil Center (Thailand) Co., Ltd.

- TANIOBIS GmbH (Goslar)

- TANIOBIS Smelting GmbH & Co. KG (Laufenburg)

- TANIOBIS Co. Ltd. (Map Ta Phut)

- Tatsuta Electronic Materials Malaysia Sdn. Bhd.

Quality Management Department Activities

The Quality Management Department is in charge of planning, proposal, promotion, and oversight for enhancement of Group-wide quality control. This department is also engaged in clarifying Group-wide QMS requirements, improving the effectiveness of internal quality audits, supporting quality improvement activities and quality control training at manufacturing sites, introducing DX to quality management tasks.

Liability Claims

In fiscal 2024, no claims were pursued under the Product Liability Act due to personal or property damage caused by defects in products made by Group companies.

Providing Information on Products and Services

In accordance with the Basic Quality Policy, the Group provides customers with information on our products and services through product specifications and Safety Data Sheets (SDS)*. For example, sulfuric acid sold by Group companies is designated as a deleterious substance under Japan's Poisonous and Deleterious Substances Control Act. By limiting our business partners to sellers of poisonous or deleterious substances and issuing SDSs, we strive to prevent serious negative effects on the occupational health and safety for our customers and their employees after delivery.

- *Safety Data Sheet (SDS): A document containing information on the hazards and toxicity of chemicals to ensure safe handling

Initiatives With Suppliers

Cooperation with suppliers is essential for thorough quality assurance. Our efforts include conducting regular evaluations and quality audits for JX Advanced Metals Group suppliers based on quality control criteria and requirements, reducing quality risks, and improving the quality level of our suppliers. We also conduct Supplier Questionnaire to promote mutual understanding with our suppliers.

Promotion of Personnel Quality Education

The Group ensures that all employees are thoroughly familiar with the Basic Quality Policy through

quality control training. In addition, we provide quality control training to all employees to improve

their problem identification and resolution capability, help them to logically infer the root cause of a

problem, independently resolve problems, and improve the quality of their work. These training programs

range from introductory to advanced courses according to the level of the participants. The programs

reflect carefully planned courses according to job rank and years of employment, and have become an

established part of employee training.

A total of 513 employees completed quality control training in fiscal year 2024. In fiscal year 2025, we

aim to train over 500 employees, further strengthening our commitment to talent development.