Metals & Recycling

Business Overview

The JX Advanced Metals Group operates an integrated metal smelting and recycling business. From copper ore and recycled raw materials such as end-of-life home appliances and electronic equipment, we use a highly efficient smelting process to produce refined copper with purity of 99.99% or higher. We also produce precious metals, minor metals, and other products such as sulfuric acid as byproducts of the copper smelting process. In addition to using these products to make our advanced materials, we supply them on a stable basis within Japan and Asia, as well as throughout the rest of the world. The Saganoseki Smelter &Refinery of JX Metals Smelting Co., Ltd. employs an environmentally friendly copper smelting method whereby the reaction heat generated by oxidation of the sulfur contained in copper ore is used for melting, and the surplus heat can be used for processing recycled raw materials. By increasing the volume of recycled raw materials processed in this way, we are contributing to the creation of a sustainable, recycling-oriented society. Furthermore, we are helping to prevent environmental pollution through our detoxification of industrial waste , which leverages incineration and melting technologies cultivated in our smelting operations to achieve zero emissions—no generation of secondary waste requiring disposal in landfills.

Business Areas

Click here for further details.

The Goal of Our Business Operations

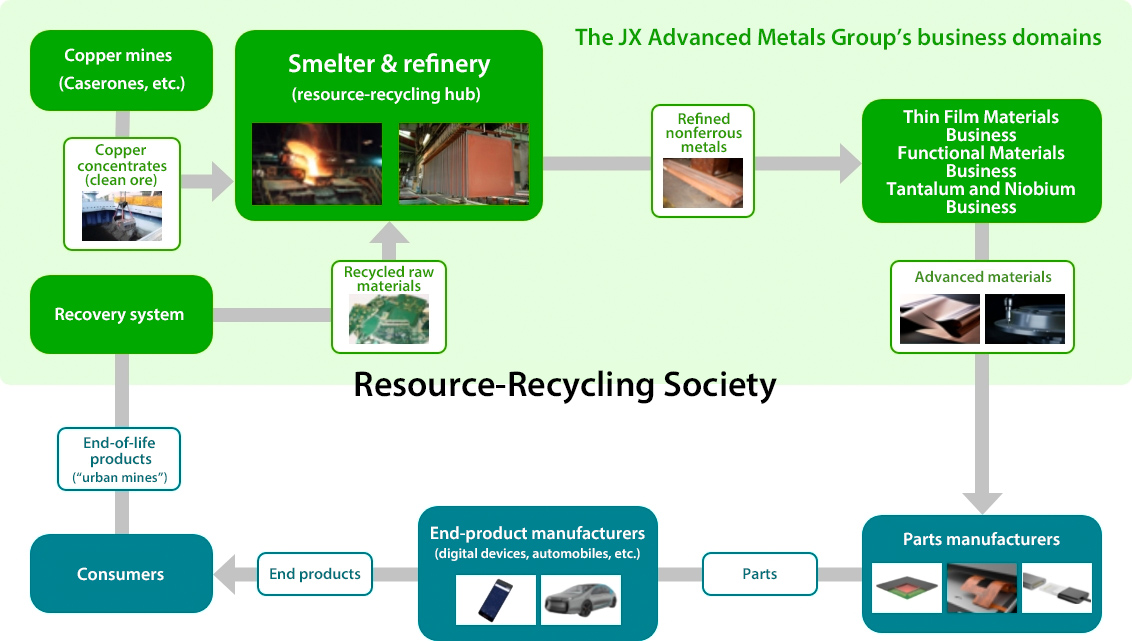

The Resource-Recycling Society Targeted by JX Advanced Metals

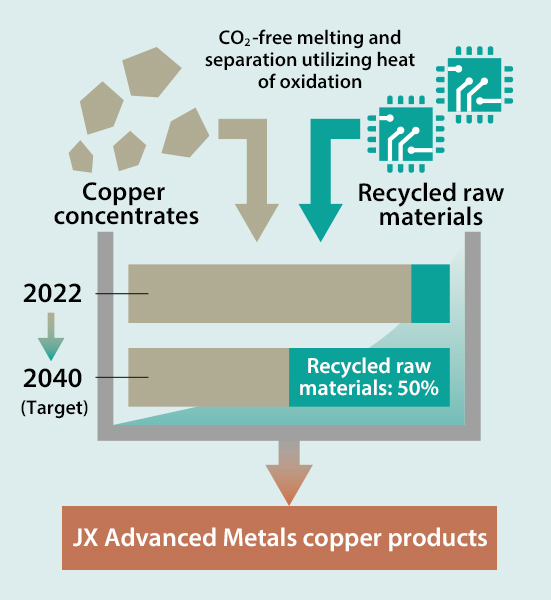

Production and Supply of Sustainable Copper through Green Hybrid Smelting

Increased use of renewable energy and electrification in multiple industries and business sectors is believed to be essential for societal decarbonization. Copper is an essential material for putting these innovations into practice on a worldwide scale.

The Saganoseki Smelter & Refinery of JX Metals Smelting Co., Ltd. is increasing its processing of recycled materials using Green Hybrid Smelting, which makes full use of the oxidation reaction heat generated by the copper ore itself to minimize the volume of fossil fuel used. We believe that copper produced using this process is the optimal form of sustainable copper for achieving our dual missions of offering a stable supply system to support growing demand and conducting ESG-oriented production and supply (characterized by decarbonization, a circular economy, etc.). We will continue developing the necessary technology and establishing the capacity to collect and process more recycled raw materials, aiming to raise the percentage of recycled raw materials used in our copper smelting to 50% by 2040.

Operational Processes

Details of Operational Processes

1. Copper concentrates

The copper concentrates offloaded from ships are carried to stockpile domes, where they are sorted into different types for storing. Multiple types of copper concentrates are mixed together and sent to a flash furnace.

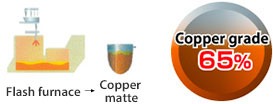

2. Flash furnace

The copper concentrates are blown into a flash furnace along with oxygen-enriched air. An instantaneous oxidation reaction inside the furnace causes the copper concentrates to melt from the resulting heat. Copper matte with a grade of approximately 65% then separates from the slag consisting of iron oxide, silicate, and other components.

3. Converter furnace

The matte created in the flash furnace goes to a converter furnace. Oxygen-enriched air is blown into the converter furnace and the copper matte is oxidized, becoming blister copper with a grade of approximately 99%.

4. Anode furnace

In an anode furnace, butane gas is blown in as a reducing agent, removing the oxygen from the blister copper to raise the grade to 99.5%. The resulting blister copper is cast in a casting machine into anode plates for the electrorefining process.

5. Electrorefining

The cast anode plates are alternated with stainless steel cathode plates in electrolysis tanks filled with copper sulfate solution, and a direct current is introduced into the solution. The copper portion of the anode plates is dissolved in the copper sulfate solution and adheres to the cathode plates.

6. Refined copper

After about 10 days of electrolysis, the adhered copper is stripped from the cathode plates, and the final product is shipped as virtually pure refined copper, and copper cakes and billets. Rated highly for their quality worldwide, these copper products are used for wires and cables, rolled copper products, and a wide range of other purposes.

7. Sulfuric acid

The exhaust gas emitted in the flash furnace and the converter furnace contains highly concentrated SO₂ (sulfur dioxide) gas. This exhaust gas is recovered using a waste heat boiler and dust is removed with an electrostatic precipitator, after which it is sent to a sulfuric acid plant. The plant manufactures and ships concentrated sulfuric acid and oleum (fuming sulfuric acid).

8. Precious metals & minor metals

The precipitate containing valuable metals produced by electrorefining is processed to extract precious and minor metals such as gold, silver, platinum, palladium, selenium, and tellurium, which we sell as products. By efficiently extracting the valuable metals contained in copper concentrates and recycled raw materials, the Group is helping to make effective use of limited resources.

9. Collection

A wide variety of recycled raw materials are recovered, including metal scraps produced by manufacturing plants and discarded electronic devices. Having set up collection centers and other operating sites in Taiwan, the US, and Germany, the Group now has an international collection network.

10. Pretreatment

Recovered raw materials undergo pretreatment at processing centers, which can include incineration, crushing, or other processes, depending on their shapes or other properties.

Products

As a world leader in nonferrous metal smelting, the Group provides society with stable supplies of copper, sulfuric acid, precious metals, minor metals, and other products, which are essential to the provision of social infrastructure. For further details, see the individual webpages below.

Operating Sites

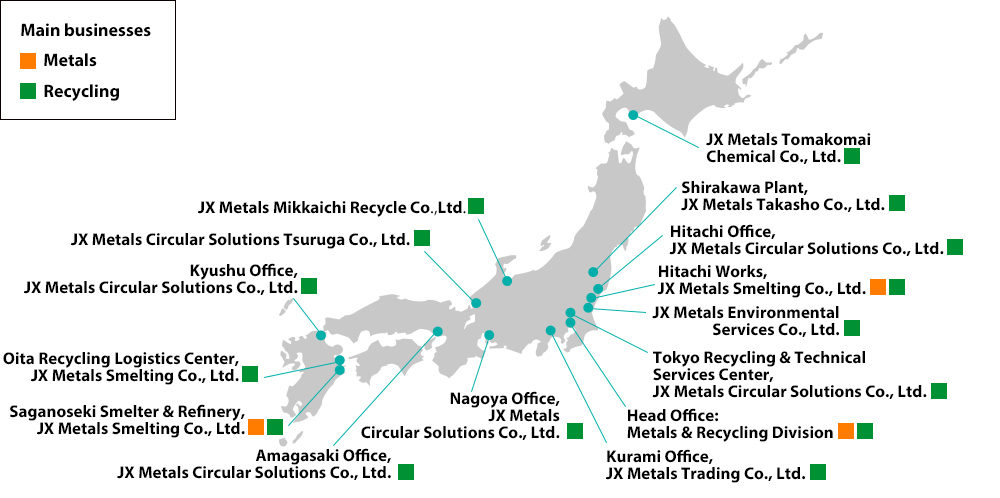

Operating Sites in Japan

In addition to collecting recycled raw materials on a stable basis by building a nationwide collection network, we leverage the strengths of individual Group operating sites to efficiently smelt metals, process recycled raw materials, and treat waste. Following collection, recycled raw materials are pretreated within the Group as necessary, then transported to the Saganoseki Smelter &Refinery of JX Metals Smelting Co., Ltd., where they are centrally processed as raw materials for copper smelting along with copper concentrates. Intermediate products from the copper smelting process and some recycled raw materials are passed on to the Hitachi Works of JX Metals Smelting Co., Ltd., where precious metals and minor metals are recovered.

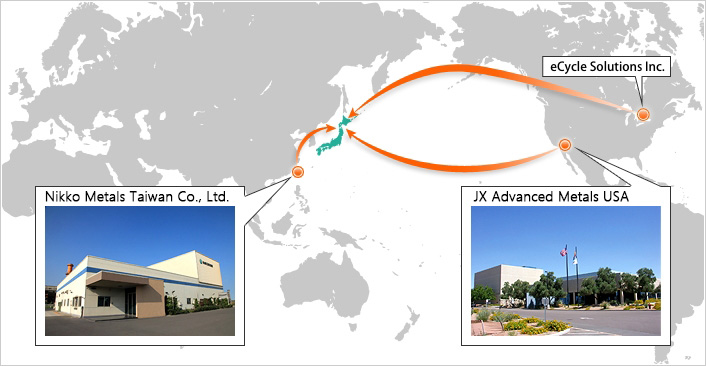

Overseas Operating Sites

The Group established a recycled raw materials collection center in Taiwan in 2010 and increased the capacity of this collection center in 2021. In 2014, the Group set up a sales office in the US. In 2022, JX Advanced Metals Corporation acquired all the shares of eCycle Solutions Inc., a Canadian company that collects and processes e-waste (discarded household appliances and electronic devices). By building up a network to collect recycled materials on a worldwide scale in this way, we are actively contributing to the establishment of a global resource-recycling society.

Zero Emissions

The treatment of industrial waste often results in generation of secondary waste such as incinerator ash or residue, which in most cases is then buried in a final disposal site or other location. Zero emissions targets industrial waste treatment that generates no secondary waste, so as to minimize the environmental burden on the next generation.

The Group is building recycling systems with the slogan, “never discard, never bury,” pursuing zero emission industrial waste treatment and nonferrous metal recycling.