Copper Titanium Alloy

C1995-GSH(HP) Extremely High Strength Copper Titanium Foil

Overview

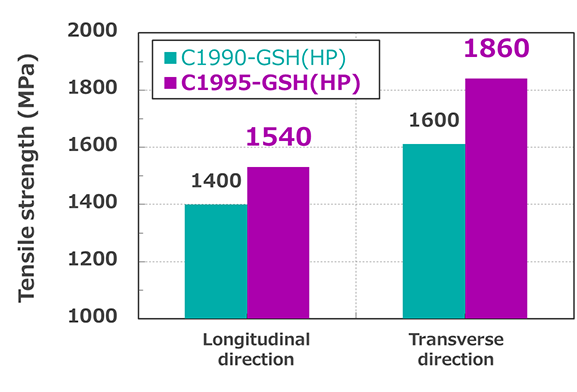

- Employing advanced thickness control techniques developed in the manufacture of treated rolled copper foil for flexible printed circuits, we have enhanced the strength compared to the conventional Copper Titanium foil C1990-GSH(HP).

- This product has the world's highest tensile strength of any copper alloy, at 1,540 MPa, and contributes to improved reliability of camera modules for smartphones as a spring material for lens support.

Features

- High strength

- Excellent spring properties

- High thickness precision

- High reliability

- Excellent stress relaxation resistance

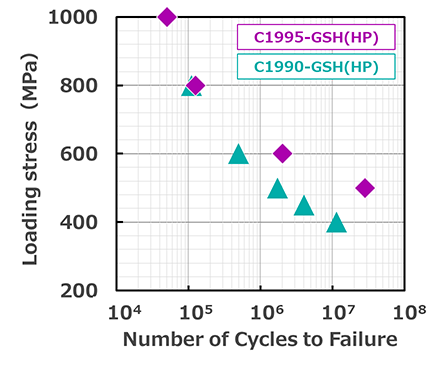

- Excellent fatigue properties

- Full-process production for quick delivery

Manufacturable thickness (typical dimensions)

- 27.5~200µm

- Maximum width 450 mm

Typical applications

- Connectors

- Spring material in autofocus camera modules for mobile phones

Table 1. C1995-GSH(HP) chemical composition (%)

| Cu | Ti | |

|---|---|---|

| Standard composition | Remainder | 4.0 |

Table 2. Physical properties of C1995-GSH(HP)

| Electrical conductivity | 8 | %IACS (@20℃) |

|---|---|---|

| Specific resistivity | 216 | nΩ·m (@20℃) |

| Thermal conductivity | 39 | W/mK |

| Linear expansion coefficient | 18.6 | ×10-6/K (20 to 300℃) |

| Modulus of elasticity | 127 | GPa |

| Specific gravity | 8.62 |

Table 3. Mechanical properties of C1995-GSH(HP)

(upper: typical values, lower: specification range)

| Temper | Tensile strength (MPa) |

Vickers hardness (Hv) |

|---|---|---|

| C1995-GSH(HP) | 1540 1400-1700 |

460 400-500 |

Figure 1. Tensile strength of C1995-GSH(HP) in Longitudinal/Transverse direction

Figure 2. Fatigue property of C1995-GSH(HP)

Contact Information

From the Web

Inquiries accepted 24 hours a day.