Copper Titanium Alloy

NKT322

NKT322

High Strength Copper Alloy for Connectors (UNS Alloy No. C19910)

Overview

NKT322 is a proprietary alloy we developed by adding small amounts of iron to Copper Titanium and further improving processes. It is notably stronger than ordinary Copper Titanium and has better bend formability.

Features

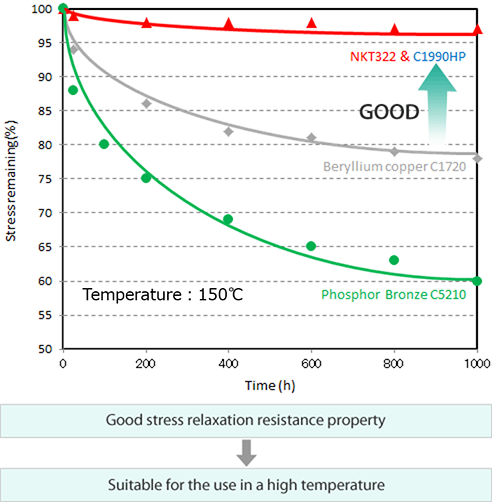

NKT322 has the highest stress relaxation resistance among conventional copper alloys and can maintain contact force at high temperatures.

NKT322 has higher strength and better bend formability compared to phosphor bronze, allowing for high contact force even in small terminals.

NKT322 has the same strength as beryllium copper and is ideal as an alternative product.

Table 1. NKT322 chemical composition (%)

| Cu | Ti | Fe | |

|---|---|---|---|

| Standard composition | Remainder | 3.2 | 0.2 |

Table 2. Physical properties of NKT322

| Electrical conductivity | 12 | %IACS (@20℃) |

|---|---|---|

| Specific resistivity | 144 | nΩ·m (@20℃) |

| Thermal conductivity | 56 | W/mK |

| Linear expansion coefficient | 18.0 | ×10-6/K (20 to 300℃) |

| Modulus of elasticity | 120 | GPa |

| Specific gravity | 8.70 |

Table 3. Mechanical properties of NKT322 (upper: typical values, lower: specification range)

| Temper | Tensile strength (MPa) |

Yield strength (MPa) |

Elongation (%) |

Vickers hardness (Hv) |

|---|---|---|---|---|

| H | 950 900-1000 |

850 800-900 |

18.0 ≧12.0 |

300 250-350 |

| EH | 970 920-1020 |

900 850-950 |

15.0 ≧10.0 |

310 280-360 |

| SH | 1020 970-1100 |

950 900-1000 |

10.0 ≧6.0 |

320 290-370 |

| ESH | 1070 1010-1200 |

1000 950-1050 |

5.0 ≧3.0 |

340 300-400 |

Correlation between Yield strength and bend formability

- Test piece shape: 0.1 mm thick × 10 mm wide × 30 mm long

For reference purpose only. They are observed values, not guaranteed values.

Stress relaxation resistance

- For reference purpose only. They are observed values, not guaranteed values.

Contact Information

From the Web

Inquiries accepted 24 hours a day