Copper Titanium Alloy

NKT322(HB)

NKT322(HB)

High Strength Copper Alloy for Connectors (UNS Alloy No. C19910)

Overview

We have further enhanced the balance of strength and bend formability by improving the manufacturing conditions with same chemical composition as the conventional NKT322.

Features

- NKT322(HB) has better bend formability and higher strength than conventional NKT322 by optimizing the manufacturing process conditions without changing chemical composition.

- Even with a thin thickness of less than 0.10mm, NKT322(HB) has high strength, making it resistant to plastic deformation and providing excellent drop impact resistance. These properties contribute to the miniaturization and weight reduction of devices.

Table 1. NKT322(HB) chemical composition (%)

| Cu | Ti | Fe | |

|---|---|---|---|

| Standard composition | Remainder | 3.2 | 0.2 |

Table 2. Physical properties of NKT322(HB)

| Electrical conductivity | 11 | %IACS (@20℃) |

|---|---|---|

| Specific resistivity | 157 | nΩ·m (@20℃) |

| Thermal conductivity | 51 | W/mK |

| Linear expansion coefficient | 18.0 | ×10-6/K (20 to 300℃) |

| Modulus of elasticity | 120 | GPa |

| Specific gravity | 8.70 |

Table 3. Mechanical properties of NKT322(HB) (upper: typical values, lower: specification range)

| Temper | Tensile strength (MPa) |

Yield strength (MPa) |

Elongation (%) |

Vickers hardness (Hv) |

|---|---|---|---|---|

| ESH | 1050 (980~1200) |

1000 (950~1050) |

7.0 (≧2.0) |

340 |

| XSH | 1100 (1030~1250) |

1050 (1000~1100) |

5.0 (≧1.0) |

350 |

- Standard values are shown for tensile strength, Yield strength, and elongation, while typical values are given for Vickers hardness.

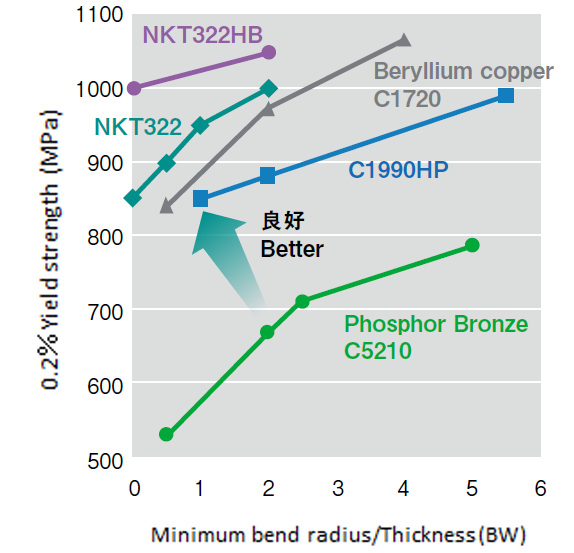

Correlation between Yield strength and bend formability

- Test piece shape: 0.1 mm thick × 10 mm wide × 30 mm long

For reference purpose only. They are observed values, not guaranteed values.

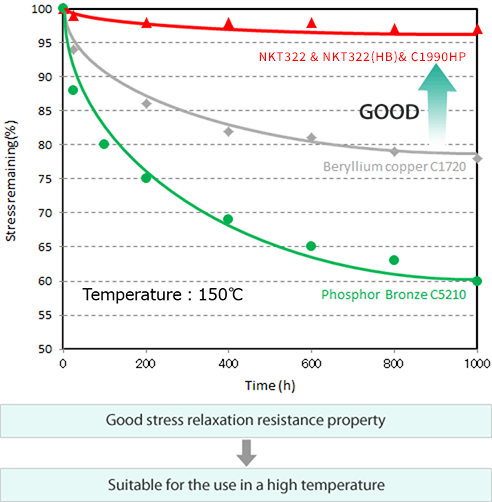

Stress relaxation resistance

- For reference purpose only. They are observed values, not guaranteed values.

Contact Information

From the Web

Inquiries accepted 24 hours a day