HG ― Flexible rolled copper foil

Applications

- FPC for fine pitch

- FPC for high frequency

Features

- The feature of HG foil is to have very fine grains with random crystal orientation.

- Fine crystal grains improve circuit linearity.

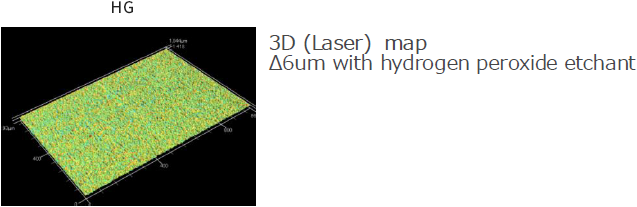

- Fine crystal grains enhance smoothness after soft etching.

- Due to the high elongation of HG, it demonstrates excellent flex capability.

Technical data and Properties

Crystal structure and outstanding properties of HG foil

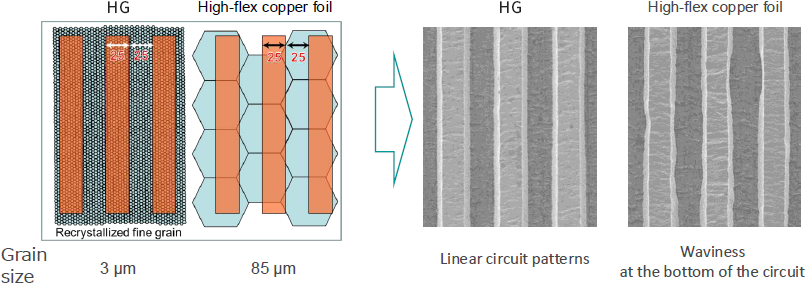

Crystal structure

HG foil excels in fine pitch properties (circuit linearity) due to its fine recrystallized grains.

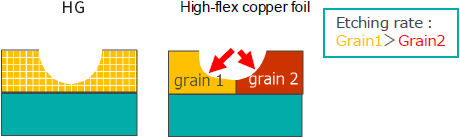

Mechanism of excellent straight-line capability on HG

Although the etching speed varies for individual crystal grains, the grains in HG are sufficiently smaller than the circuit width, resulting in minimal differences in etching behavior between adjacent grains.

The smaller crystal grains result in smaller surface irregularities after soft etching.

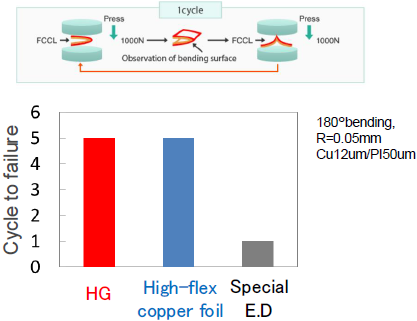

Folding resistance (static bendability)

HG foil exhibits properties equivalent to high-flex copper foil in repeated bending (i.e., folding). In the 180° repeated bending test of FCCL conducted using the method below, special electrolytic copper foil developed cracks in the second cycle, whereas HG foil and high-flex copper foil did not develop cracks until the fifth cycle.

FCCL 180℃ bending test

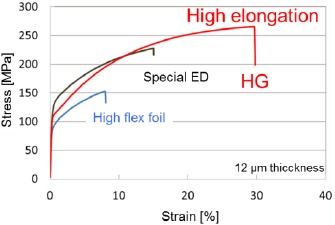

Mechanism of higher fold flex capability on HG foil

HG foil has a steeper slope in the plastic region of the S-S curve compared to other copper foils, resulting in uniform deformation without necking.

Additionally, it has a higher elongation rate than other copper foils. These characteristics allow the copper foil to deform uniformly and significantly during folding, making it less prone to necking (localized reduction in cross-sectional area), which is a cause of crack formation.

Inquiries accepted 24 hours a day.