Compound Semiconductors and Crystal Materials

CdZnTe (CdTe) Substrates

JX Advanced Metals products with their consistently high quality are winning customer acclaim and confidence. We manufacture CdZnTe (CdTe) for II-VI compound semiconductors. We supply products meeting the latest demand and product requirements.

| Product name | CdZnTe (CdTe) (Cadmium Zinc Telluride) Substrates |

|---|---|

| Primary Applications | Infrared detectors, radiation detectors |

Lineup

| Size(mm) | Orientation | |

|---|---|---|

| CdZnTe Substrates | 10×10- 95×95 |

(111),(211) |

- CdTe is also available.

| High resistivity CZT Lineup | Size(mm) | Thickness(mm) | Resistivity(Ωcm) | μτ(cm2/V) | Standard pixel design |

|---|---|---|---|---|---|

| Bare substrate | Up to 60x60 | 0.5–5.0 | 107–1011 | Electron: 1x10-4–2x10-3 Hole: 1x10-5–9x10-5 |

- |

| Planar detector | Up to 10x10 | - | |||

| Pixel detector | Up to 40x40 | Pixel pitch: 75 μm Pixel size: 50 μm |

Application Examples

Features

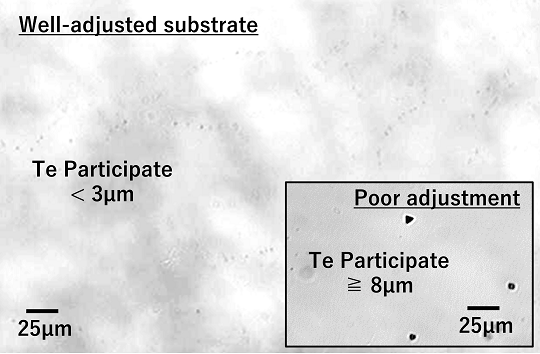

- Large-diameter CdZnTe single crystals of the world’s highest quality are achieved using our proprietary crystal growing technology.

- CdZnTe can detect radiation with higher precision than other materials, for stable X-ray detection.

- Our CdZnTe substrates with uniform Zn concentration enable customers to produce larger infrared sensors.

Features of high-resistance CdZnTe substrates for radiation sensor use

(left: planar device; right: pixel electrodes)

- High resistance reduces dark current.

- Polarization does not occur, thanks to the outstanding stability.

- Excellent interoperability with application-specific integrated circuits (ASIC) is possible.

- Can be supplied as bare substrate or with planar device or pixel electrodes.

Contact Information

From the Web

Inquiries accepted 24 hours a day